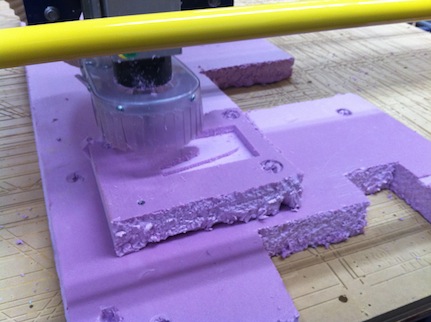

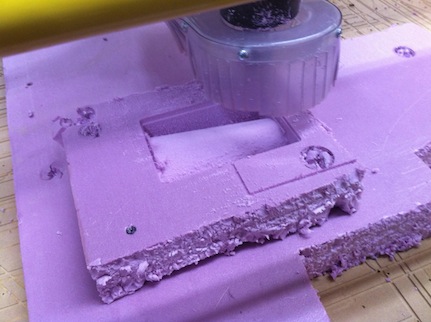

After attending a vacuum forming demonstration by Justin on Monday, it seems like a good way to make a foodsafe glass. I ordered a clear 48"x48" PETG sheet (McMaster #85815K62); while I was waiting for the material to arrive, I designed a mold in SolidWorks and milled it out of foam on the ShopBot (note: select the top surface correctly! If PartWorks3D suggests a toolpath that doesn't make sense, you probably set the wrong top surface). To make a pint glass, I used two blocks of foam. After the ShopBot was done I cut out the two parts out of the foam frame, filed them, and glued them together. Toni suggested applying gesso to the mold to protect it from the heat during vacuum forming, and was even nice enough to do paint it for me (thanks Toni!).

The material arrived on Thursday. As the pictures show, the first attempt was a complete failure. There was too much extra material, which wrapped around main part. So I tried again. This time I drilled a hole through the mold to improve suction and to prevent the foam from imploding. Also, I cut out some of the extra material and placed the mold on a pedestal, to allow extra material to fall down instead of wrap around the mold. There was certainly some improvement, but not enough to make a glass I could actually use.

After spending over two days on vacuum forming and the required preparations, I realized I didn't have much time. I decided to work on controller and application code, and leave the glass making for later. My backup plan--to which I eventually resorted--was to tape the traces onto the exterior of a commercial glass.