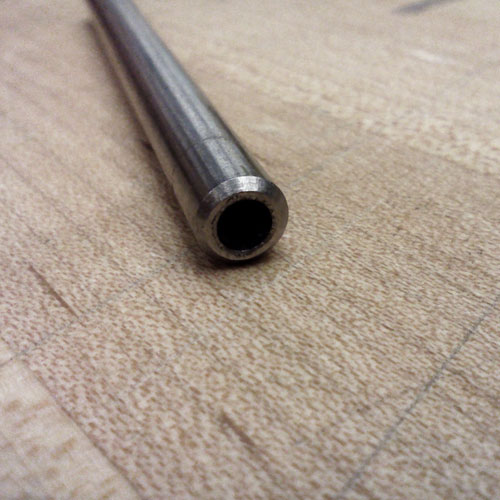

For the MTM this week I worked mainly on the spindle assembly and got to work the lathe to bore out the end of the drive shaft to make room for the end mill.

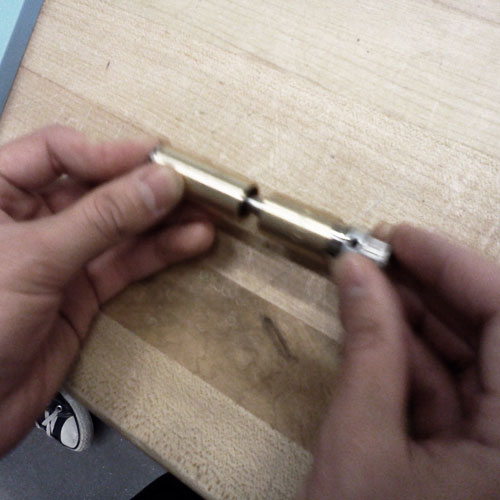

I believe we missed some parts in the assembly, some intermediate bearings.

caption.

caption.

caption.

caption.

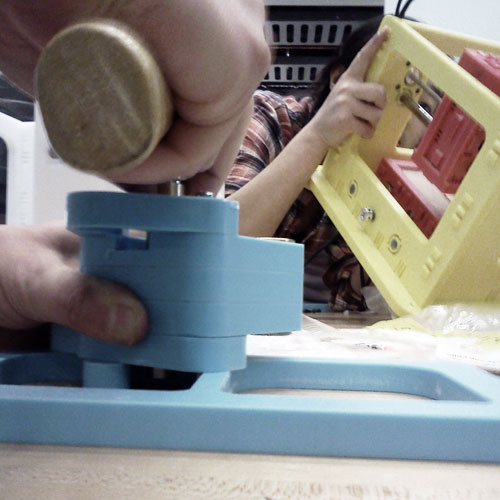

In the end, we hammered the whole assembly into the HDPE assembly. We also hammered the shaft into the bearings which bent the flange on the timin belt pully. Justin and Jonathan had a better suggestion which consisted of cooling the shaft in a freezer and heating the bearing in a toaster oven which would let them slide together pretty excellently. When they return to room temperature, they would be very tight. No hammering required.