stepper figuring?

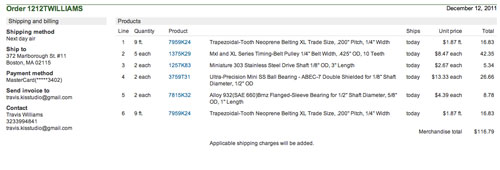

order

order

What will it do?

stepper figuring? |

|

order |

|

order |

What will it do?

This video shows that based on the configuration of attachments between the pieces, a different actuation cofiguration can result. It can be a blackout shade or a table top. |

|

because a lot of my projects this semester have had a lot to do with movement and hinges, I wanted to continue that direction. I was interested in live hinges / curved surfaces from wood veneer. I used this light by industrial designer Lydia Cambron as a jumping off point for patterns that lead to folded plywood shapes. |

|

Cambron's lamp cutout pattern. |

|

Lamp cutout tests for grain direction study. |

|

Bending perpendicular to the grain is less desirable. Even in bristol board. |

|

Paper folding studies |

|

flat sheet. |

|

Curved in opposite directions |

|

This is really leading nowhere. Sort of. |

|

Some hope for something useful. |

|

folding offset. |

|

Offset folding aggregated. |

|

Testing the actuating technique. |

|

First try was less than a success. The frame was very flimsy and the string really got stuck a lot. |

|

So, a new frame using the waterjet. |

|

test surface with non automated / programmed actuation technique. The wood handles would be replaced by programmed stepper motors. |

Not a complete success, but a useful test. |

What's been done before?

This video is not my work, but it shows an electronically actuated surface. I think my precedent example is more related to the bent plywood lamp than this. |

What will you need to develop?

Unit clipping, Unit to string connection, Frame or no Frame?, String or timing belt?, code for Stepper motor, test at full scale using aircraft plywood.

What will be done when?

1. Frame

2. plywood units

3. stepper motor coding

4. stepper motor assembly

What materials and components will be needed?

1/16" aircraft plywood.

2(?) stepper motors

timing belt

either 1/2" plywood/OSB or 1/16" to 1/8" aluminum sheet for the frame unless it turns out to be a better project as a frameless surface ... wha?

What will it cost?

4x4 1/16" aircraft plywood (2) $120

stepper motor (2) $10

timing belt (2) each around 120" (77") long $10

4x8 1/2" OSB (1) $7

total = $150