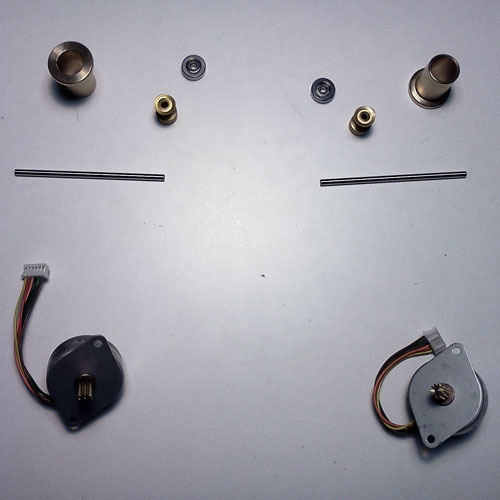

mechanical components

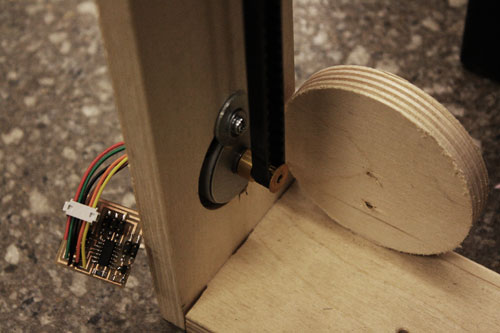

stepper motor at bottom of frame

timing belt pulley assembly

from paper to wood

|

mechanical components |

|

stepper motor at bottom of frame |

|

timing belt pulley assembly |

|

timing belt pulley at top of frame |

|

First attempt at wood slats and their connection mechanisms to each other .... |

|

and to the timing belt |

|

1/16" was not flexible enough. |

|

slat iteration |

|

slat iteration |

|

slat iteration |

|

timing belt location issues |

|

many iterations. |

|

tabbed attachment |

|

slats in frame |

|

timing belt binding issue |

|

The timing belt came not closed, so I made a clamp on the waterjet to try and pinch the ends of the timing belt together. |

|

My clamp snapped in half. |

|

So I took two halves that had slots and bolted them together. |

|

The over/under front/back theading of the timing belt through the slats. Notice the final detail only has a timing belt connection on one end. |

Works with human power. |

|

This image shows surface normals. I decided to try and include some on my surface to accentuate the curving action. |

|

My first pass was molding straight from gessoed foam. |

|

But I used smoothcas 300 and it fused with the gesso, destroying the mold. |

|

The second mold I made a positive from foam (used the ball nose - mistake) |

|

I used the oomoo mold to mass produce the "vectors" |

|

They fit into slots on each of the slats. |

|

actuated. |

|

|

actuated |

|

actuated |

|

code adjustment for regular stepper movement |

el fin. |