Week Six: Molding and Casting

Our assignment this week was to make a mold and cast something. The suggested way of doing this was to make a positive in either wax or modeling foam, then make a negative in silicone, and make the final casted part in Drystone and/or Hydrostone.

I decided I really wanted to make a to-scale model of the Great Dome. I had done this once before, for a paperweight for 2.008. However, the material given in 2.008 for paperweight-making was 5/8" tall, so I had a really tiny dome, and it was pretty disappointing.

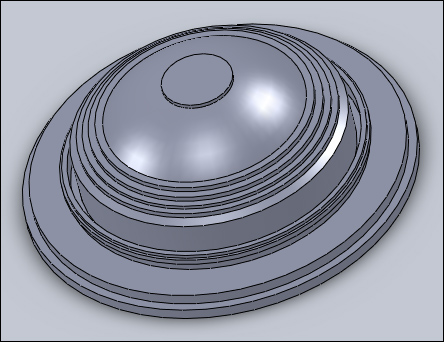

As always, this started with a Solidworks model. My friend has a to-scale dimensioned .png image of the dome that has been passed down since who knows when, so I traced the image and revolved the sketch to make the dome. I then remembered that the wax is only 1.25" tall, so I tried to limit this dome to about 1" tall. This meant I had to remove some of the lower details, which I was a tiny bit disappointed by, but oh well.

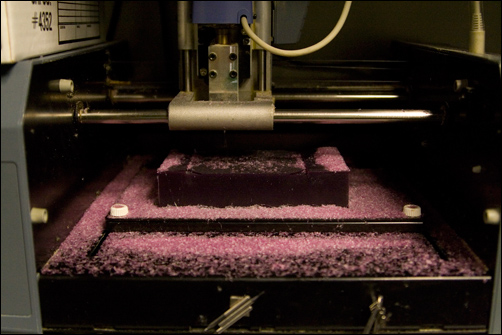

I then took my model, converted it to an .stl file (case matters here -- for some reason Solidworks converts to .STL file, but fab modules only reads .stl files), and fed it into fab modules to generate a .png image. I then hot glued the piece of wax down to the Modela, set my z 0, and set up the z settings on the Modela. I went with an overlap of 0.5 (which turned out to be way too high), a z step of 1mm, and set my z top to 0mm. I used a feed rate of 20 mm/s due to the recommendation of classmates, and a jog speed of 1mm/s (default). I set my x and y zeroes, and started my roughing pass.

As it turned out, using the default overlap of 0.5 was way, way, way too slow. I think the whole roughing "pass" took about 5 hours....including when I got fed up halfway through and decided it didn't really need to cut that far out for making the silicone wall thick enough. For comparison, the aluminum dome paperweight took all of 10 minutes (although the machine was already set up, but still). And I still didn't make the finishing pass! Anyway, I did a finishing pass which took about 15 minutes, but at that point I'd gotten really fed up and just did an xy path with .2mm z step and didn't do an actual finish pass because I didn't like how it looked, and it turned out not as smooth as I would've liked. If I had bothered staying around for another hour or so I probably would've gotten a nice finish, but it was around 4am at this point and I was pretty fed up with watching the Modela.

On Friday I went into the shop and cast silicone in the wax mold. I first clamped two pieces of MDF around my mold so the silicone wouldn't spill out due to the shape of my mold. I then mixed the OOMOO 25 Parts A & B in 100:130 weight ratios. I poured my silicone in only to realize I needed another ~1/2cm of silicone, and hastily made a tiny bit more by eyeballing the volumes because the scale was in use and I didn't want things to cure. This actually worked out fine, although the silicone took more than 75 minutes to achieve a non-tacky state.

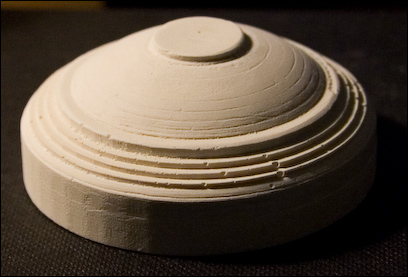

Next was casting the final piece out of drystone. The drystone mixes in 5 drystone:1 water weight ratios, which creates this pretty viscous fluid. I poured it into the mold slowly, and after it was all in I realized it was pretty bubbly, so I hit the silicone mold against the table a few times to try to get the air bubbles out. This seemed to get a lot of them to rise up, so I stopped after a while. Unfortunately, there ended up being a few air bubbles still stuck on the bottom, and I learned that you should tap the drystone while it's still in the cup to minimize air bubbles.

I then tried casting hydrostone. The hydrostone had roughly the same weight ratios, but was a little less viscous. This time I did tap the cup against the table before I poured, and the hydrostone piece turned out seemingly air-bubble free. The hydrostone also took a much longer time to set -- I think the drystone took less than half an hour, while the hydrostone took more than an hour before it was no longer warm (exothermic processes are pretty interesting!). Anyway, both molds took a little bit of filing action due to my impatience with the Modela, but turned out pretty well.