3d scanning and printing

from physical to digital and back again

there were two main aims for this week: to scan an object and to print an object. my personal aims were to try and scan and print objects that are hard or impossible to machine or replicate otherwise.

Scanning

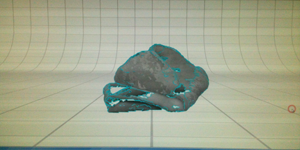

using dough, I made amorphous shapes which I tried to scan. I ran into a couple of barriers arising from the following issues

1. It's important to be able to scan from different angles, and soft models can's be picked up and rotated without ruining their integrity.

2. If you can move the scanner around the object then this can be diverted.

3. The texture wasn't great for the scanner.

Result: Scan had many holes. Too many to rectify for 3D printing.

Printing: Replicator

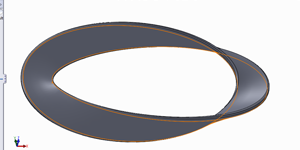

I twisted a rectangle along the profile of an oval in Solidworks in the same way you would make a mobius strip. The quality of the print varies along the model.

Printing: Dimension

The quality is much higher. In order to remove the support material the parts remained in the bath for just over a day, so further comparisons will follow.