Molding and Casting

multi-output molds, lego men and aliens

My goals for this week: To make a mold and cast with it.

Inspiration: Can a single mold output different shapes?

Casting is classically used to create many identical pieces, but what if you could create a mold that produced hundreds of different designs, or variations from one mold? For example a person with a head in different positions, or a tree with branches in different orientations.

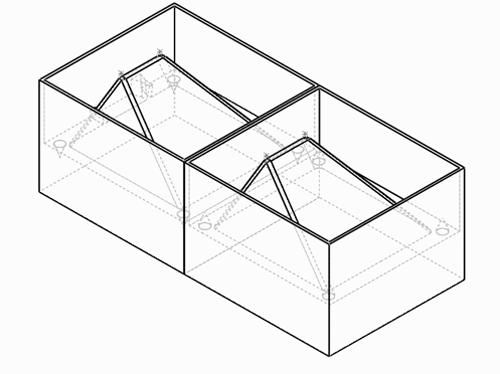

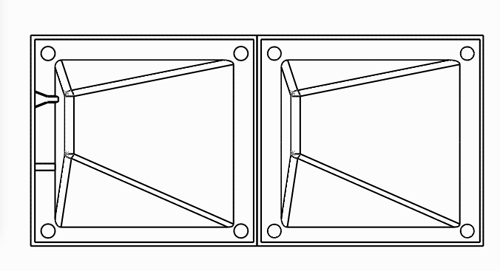

1. Design a part that can be machined with the Roland Modela, which means no undercuts.

I used Solidworks to design the mold, including an air-hole and an inlet. It was tricky to find a complex enough shape to show differences but a simple enough shape to make in a two part mold.

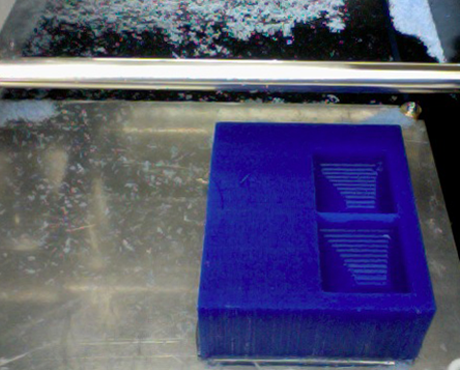

2. Make the parts using FabModules and the Roland Modela machine

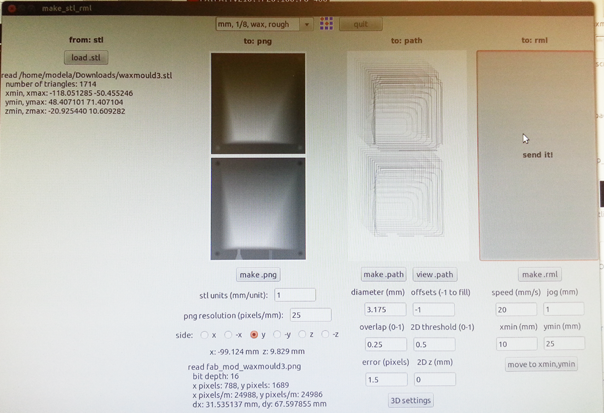

The FabModules take .stl files and create a bitmap image with the shallowest point to cut documented as white, and the deepest point is marked as black.

Make sure you have no through holes, as these will be marked as black and the machine will miscalculate.

I had the FabModules set up as shown in the picture.

When drilling, glue the wax to the base with hot glue. Make sure the bit is set high enough to clear the wax when initialising the xmin ymin location.

3. Make a soft, negative mold in silicone.

Measure the volume necessary using water. Mix the parts really well, and remove air bubbles by tapping the cup on the table, using a vacuum chamber and pouring out the silicone using a really really fine stream.

Leave for a minimum of 1.5 hours.

You can see here that my locaters were too small for the mill-end so I have been left with small holes in the corners of each part.

4. Cast the part

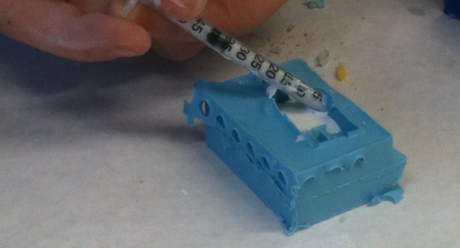

I found using a syringe really useful for getting the plaster into the mold, and play-dough was a great support for the base.

5. Results

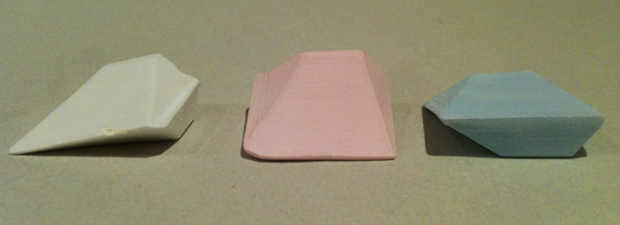

Two Part Mold

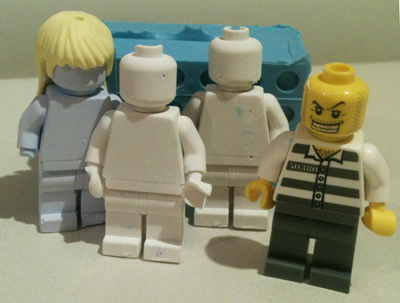

Playing with Lego

I wanted to make little chocoloate lego men, so set about making a lego mold for a lego man. The pieces fit together so tightly that the lego made a perfect mold. I still need to experiment with split lines for getting the hands out, but I am approaching a complete lego man.

Aliens and Sheep

With Catherine, we started to experiment with different shapes that we could cast. Pip showed us a trick with sellotape as a splitter and we used that as in inlet for the material.

one three-eyed alien!