Flexible LED Array

Vinyl cutting and charlieplexing

The goal for this week: Use a microcontroller to make an output do something.

So, charlie what?

I had not heard of Charlieplexing until this week. For those students who are newer to the electronics side of things: Usually when controlling LEDs with a microcontroller each pin controls one LED. A 1:1 ratio means multiple microcontrollers for arrays of anything over 10 LEDs. With Charlieplexing, you can control a large number LEDs using just a few pins. To be precise, one pin per row. n pins can power n2-n LEDs

Method

1. Vinyl Cutter

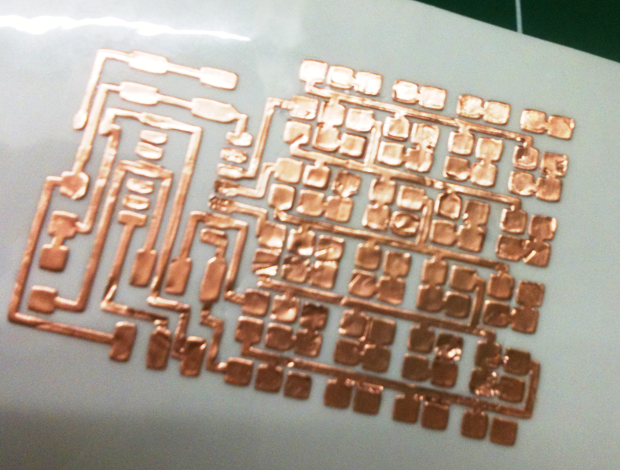

The flexibility of the vinyl cut circuits is something I am planning to use for my final project, so I decided to make the Charlieplexing LED example from Neil's page with the vinyl cutter. I used force 75 and speed 2.5(tutorial)

2. Weeding the Board

The Charlieplexing traces are cut very close together so weeding was a little tricky, especially in between the little pads for resistors and LEDs.

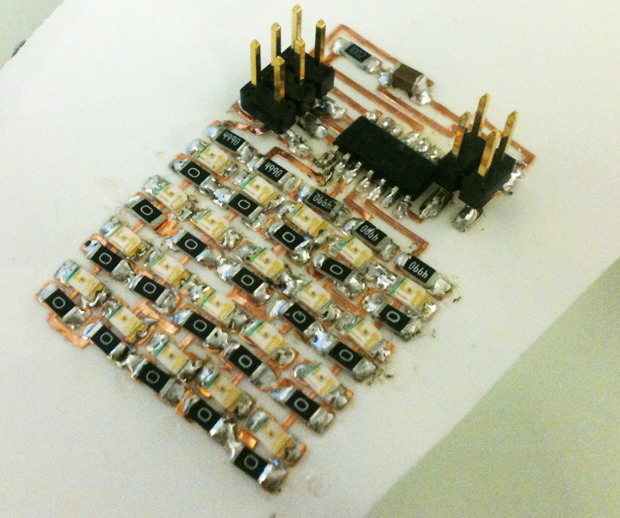

3. Stuffing

Soldering a vinyl cut board needs the greatest speed and deftness of hand. The small size and lack of a flux pen meant I over heated the traces a little and ended up with a decidedly messy board.

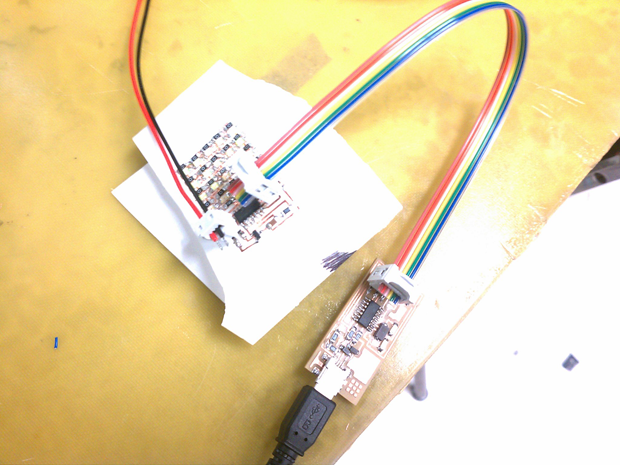

4. Programming

In order to program the charlieplexing board, you need to run "make", then " program-usbtiny":

5. Troubleshooting

When I tried to program the board it wouldn't program, and I got the response:

make: ***[program-usbtiny] Error 1

This usually means that there is a problem with the board. Some of the vinyl traces had moved, and some of the connections were either weak or too large.

6. Success!

7. Programming the .c file:

I started making changes to the c file to alter the light patterns. My goal for the final week is to create images with the LEDs, but I'm not quite there yet.