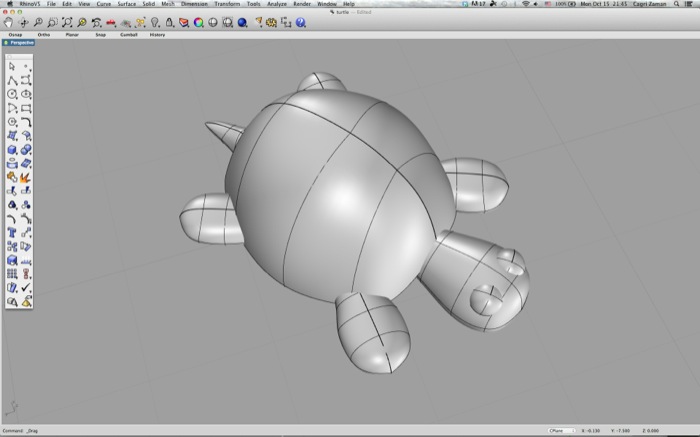

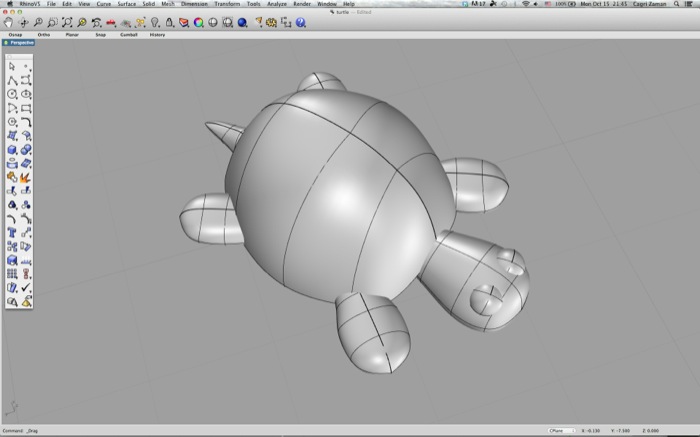

For this week, I modeled a turtle for molding and casting. I used rhino for modeling and exported stl.

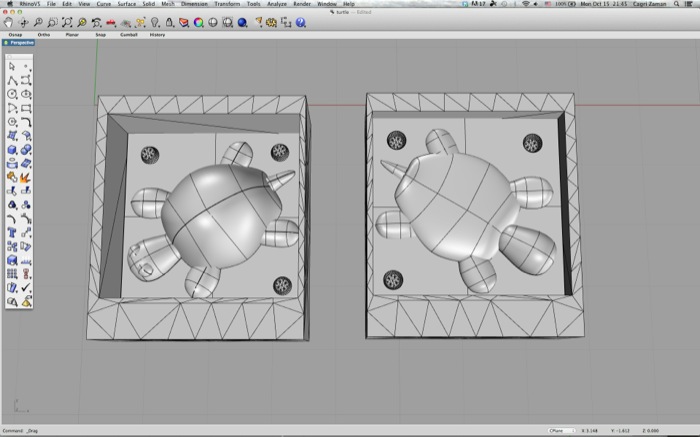

After creating the turtle, I split it into two parts in order to create two molding pieces.

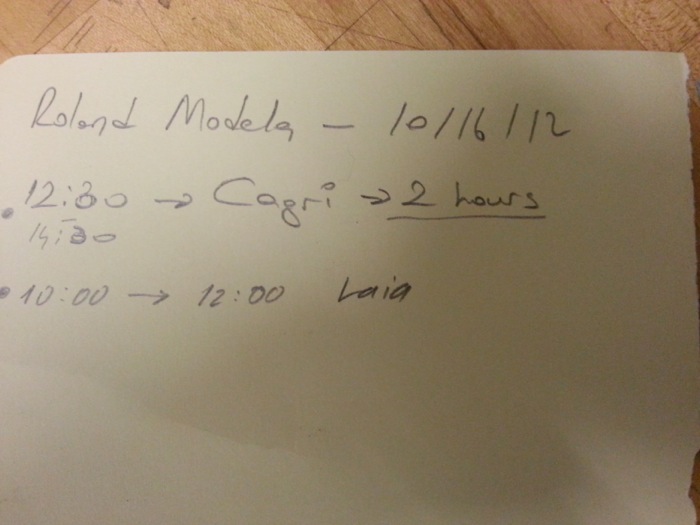

Milling took too much time. I reserved 2 hours for this purpose, which eventually ended up being 6 hours just for milling.

I made several attempts for milling. In one of them, in the finishing phase coordinates massed up and it drill through my object.

In an other attempt, since I did not tight the set screws enough, milling head pull off from the machine again drilling trough my object.

In the end I was only able to create upper part, and keep the lower part for another day.

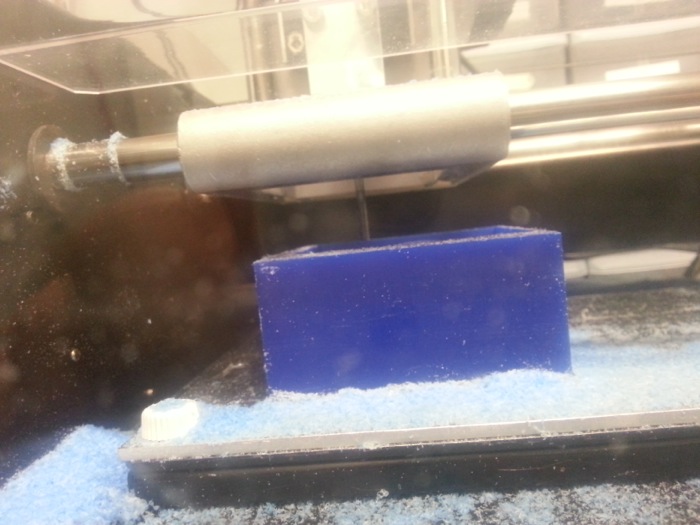

Wax molding.

It take a little time to remove bubbles from rubber, I mixed the parts in a wrong way which leaded a lot of bubbles inside it. Anyway,

I was able to remove them by shaking and vibrating it.

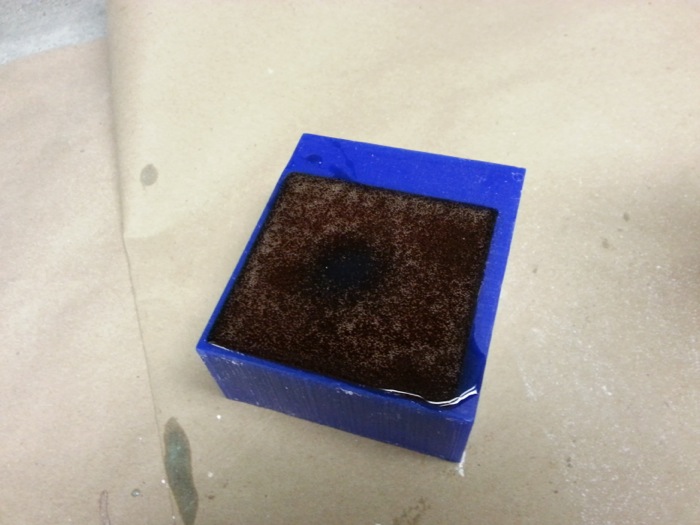

Final rubber casting.

Since my model was designed for two pieces, I had unnecessary vantilation and pouring channels in my model.

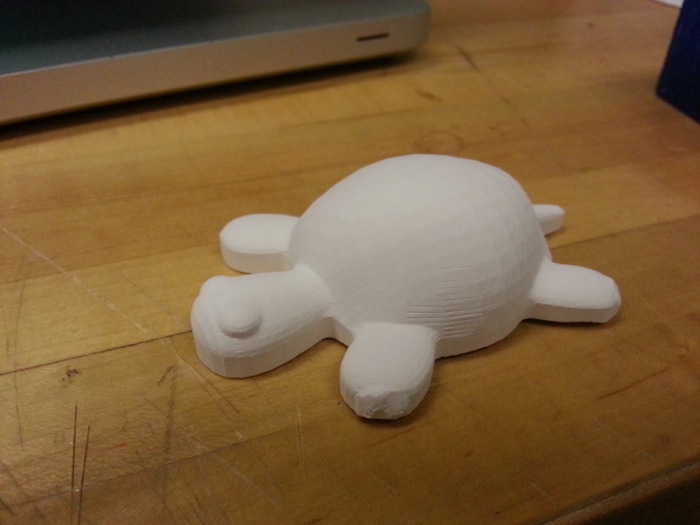

I used dry stone mix for my turtle.

The half turtle.