Week 11 - Output Devices

Chintan Vaishnav

Goal

Create a board to drive an output device. After several trials to vinyl cut different boards, I resigned to milling the speaker board.

Vinyl Cutting Trials

I experimented much with vinyl cutting this week. While I have not yet succeeded in cutting a full circuit, I can speak about several improvizations that might help. I will continue to try it to see if there is a combination of techniques that could make vinyl cutting easier.

The process for vinyl cutting has the following steps: 1. open traces png file with a fab module to convert to .camm; 2. turn on the vinyl cutter and set the role, origin, and pinch roler; 3. vinyl cut the circuit; 4. after cutting out your circuit, stick the white masking tape no the copper, remove the back sticker and stick the glossy white sheet on the other side (this sheet will be come the base for the circuit; 5. weed the excess material, and your cirtuit will be ready.

Here's what I tried

- On the fab module, I varied the setting for "force" while making a .camm file. The value that worked me for without stripping up the FR4 was 68 or 69. Above this value the sheet started to get damaged. Alternatively, at very low values (below 50) the tracks were too light, making weeding hard.

- Weeding is hard. It requires a good pair of eyes (I have high miopia). I first tried with multiple tweezers, holding the tracks I want to keep with one, and pulling what I want to remove with the other. Two tweezers help in some situation, but pressing the tracks with one tweezer muddled up the parts where the cuts were made, which complicated the furhter cutting.

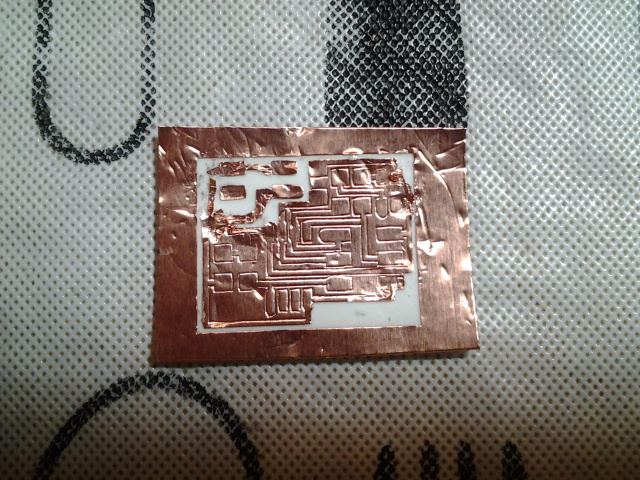

One of my many bad boards where I ultimately ended up ripping a track.

I then got into a bunch of experimentation.

Can tools help you?

- Balance the combination of tools used.

- A good magnifying glass and bright light are helpful

- Weed as much as possible with a single tweezer and chip off pieces as you go along. Thick, extended pieces of vinyl tend to rip the tracks (you want to keep) along.

- Use a pair of tweezers around close corners. But avoid using the second tweezer in open areas as they disturb the tracks.

- Hold the circuit in hand as you weed because you will need to turn it around and maybe even bend it to peel of pieces.

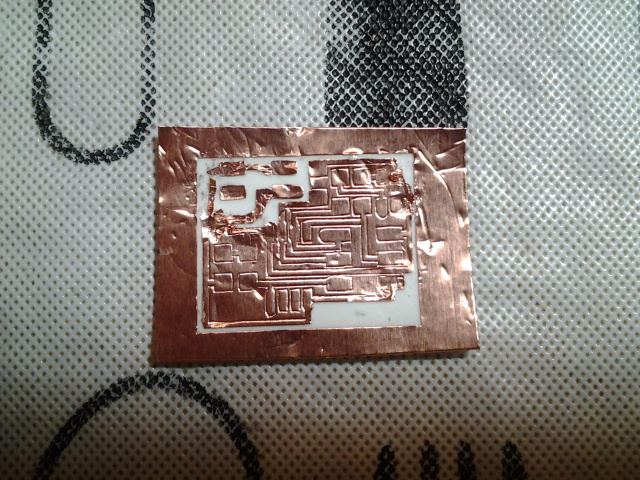

Tools I tried for weeding.

Can the Vinyl Cutter help you?

I ran a bunch of experiments with the Vinyl cutter. These experiments were along two dimensions: (a) inverting the board image to control whether the machine works on tracks or the excess material, and (b) to alter settings on the fab module to control cutting vs. etching.

Here are a few things that will make weeding easier (I am still playing with them).

- First etch the tracks and then cut them. You do have to do both.

- Etch the tracks not the excess material. To do this, you will need to invert .png of the board traces. This will make the tracks stick a bit more than the excess. Use "force" and

"offset" setting to ensure tracks don't overlap. The setting that worked best in my trial was force = 40, and offset=-0.75.

- Now cut the traces using the original (not inverted) board file.

- Follow the rest of the procedure. This circuit should be much easier to weed.

-

Speaker Board

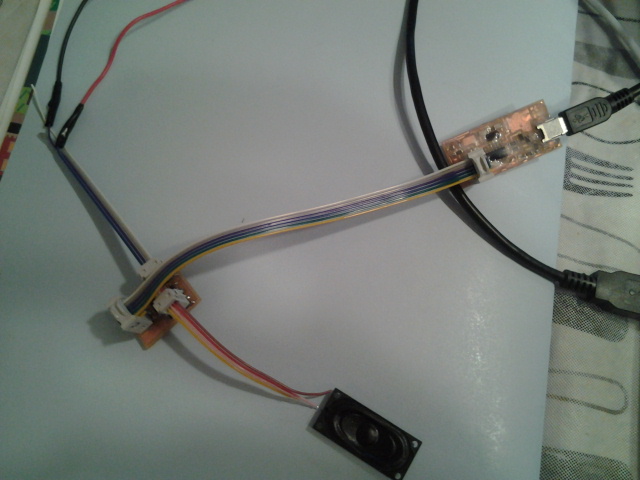

After failing to vinyl cut for two days, I settled for making a speaker board by milling and stuffing it.

speaker board setup

Milling and stuffing went fine, but I am stuck on not being able to download the program onto the board. The "make -f program-usbtiny" works only intermitantly and partially. Both usbtiny and avrisp exhibit the same symptoms.

- Most of the time, it fails with rc=-1, asking to check the board connection. The connections look right with multimeter. I have resoldered the chip because it appeared slightly slanted and not sitting properly.

- Sometimes, the make command with "program-usbtiny" does go through most of its operation, but then stops with complains about lfuse, hfuse, and efuse. It says lfuse has changed from 62 to 0, and asks whether to accept it (y/n). Answering "y" hangs the process, and answering "n" ends with an error.

Here is a screen shot.