Week Three – 3D

Scanning and Printing

Heart Rock and Datsun

Hub Cap

3D scan an object. Design and 3D print an object.

Original concept: Heart Rock

My wife found a rock in Maine with a perfect heart shape naturally embossed on it, and ever since it has been her good luck talisman and has accompanied us everywhere. We have nearly missed flights as she argued with security personnel in Central America over having a heart rock in her carry on.

So it made perfect sense to make a lightweight heart rock replica that would pass through a TSA scanner.

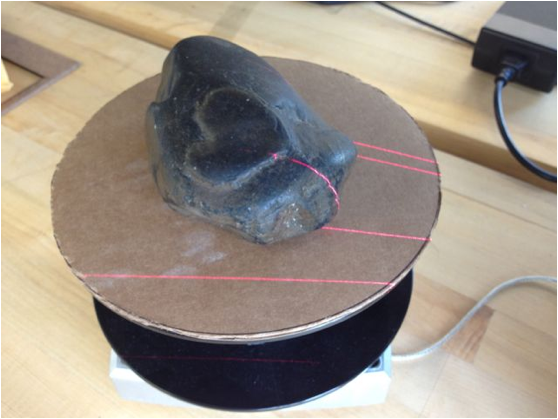

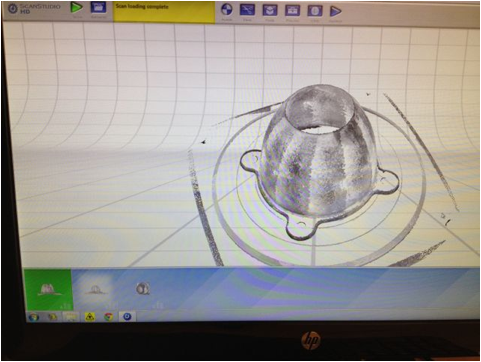

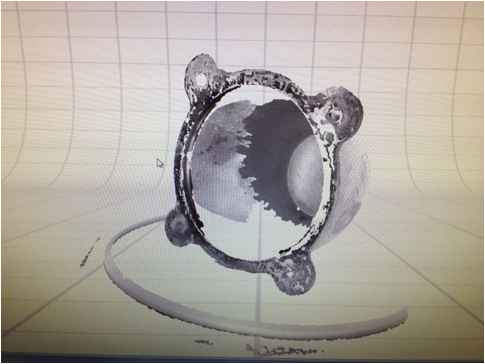

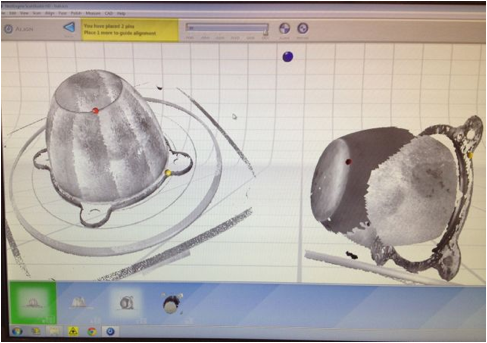

Took about 4 scans at

different angles, but they stitched together well/

I also tried using 123D Catch on the iPhone, which worked up to a point, but resulted in an incomplete image.

Take 2 – Datsun 260z mag wheel hub cover

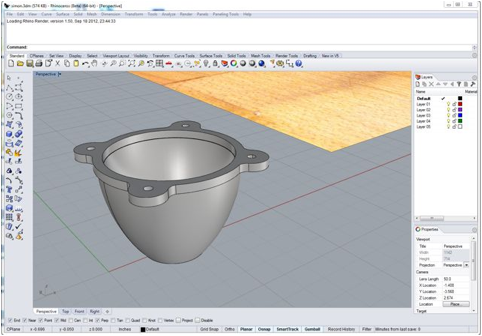

The hub covers on my wifeÕs 1974 car are original, made of chrome plate plastic, and beginning to look the worse for 38 years of wear. This seemed like a more achievable project.

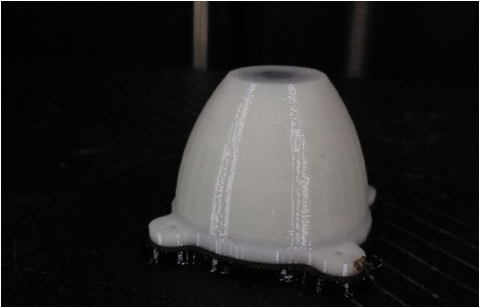

The challenge for the scanning process was reducing the shine. While most of the chrome has worn off over the years, there was enough to be problematic. A generous application of talcum powder was sufficient

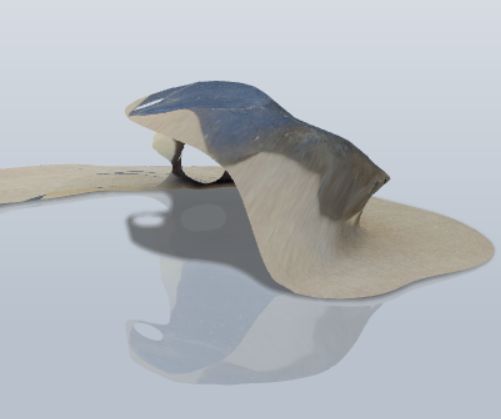

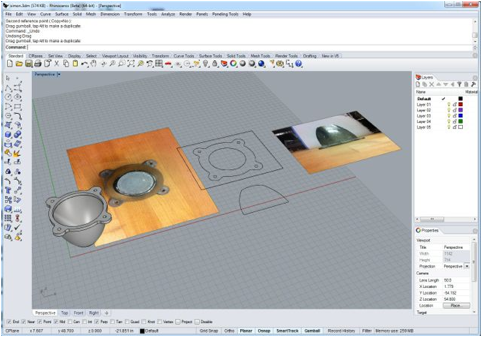

James managed to convince me that the work required to make this data set pint-ready was significantly more than designing the piece from scratch. Enter the Rhino. Starting with some photos of the piece, it probably took less that 15 minutes to create the .stl file for the printer. It would have taken me significantly longer on my own, but IÕm hoping to improve my skills in order to finish my ship project from the first week.

The result is a scaled down prototype, made out of ABS in the Dimension. The intent is to use this file to make the mould for the casting project, where IÕm hoping to make four hub covers out of an alloy.