Week 8 –

Computer-Controlled Machining

Make something Big.

Plans

delayed due to storm – unable to get machine time. My primary plan was to make a book shelf without screws or nails – essentially a

press fit where the shelves protruded through the uprights and are locked in

place by a fid (peg). I still like

this idea if I can get wood that isnÕt OSB. The other idea is to make a half model,

and it is in this pursuit that I have been spending most of my time.

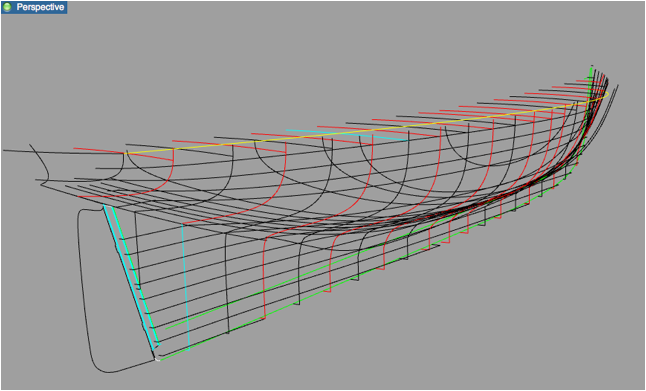

A

half model is basically a scale model of a ship profile, and is usually the

step before lofting plans for a hull.

Some boatbuilders were known to only use the

half model as a reference for a build, never referencing the actual plans

The

idea came up because Ken in the Hobby shop said that he had lots of foam that

heÕd bought from the class that he wanted to use, and that we only had

restricted time (and foam would mill faster). The plan was to mill the hullout of foam, and mount it on a piece of mahogany or

similar. I have the CAD files for

the lines of Spirit of Bermuda which IÕve been wanting to use for a press-fit

model – I figured his would be an opportunity to manipulate the flat

drawings into a 3d model, and get better acquainted with Rhino.

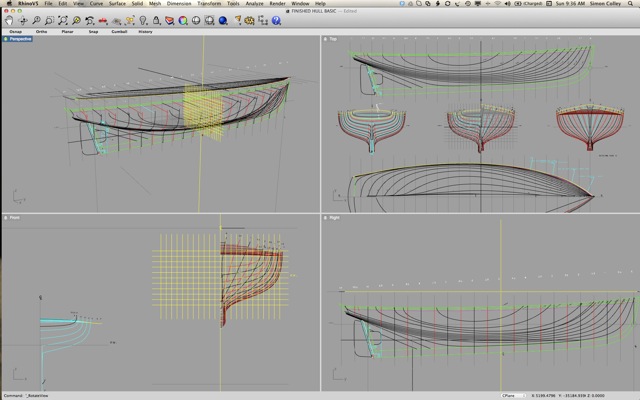

Ended

up spending days on Rhino. I found

a tutorial on lofting hull forms from transverse curves which was informative

The

method was for cargo ships, which have relatively box-like hull forms, and the

method was described as not very effective foe sailing vessels, owing to their

more complex hull shapes. I

interpreted this as a need for more data, in the form of the longitudinal

curves.

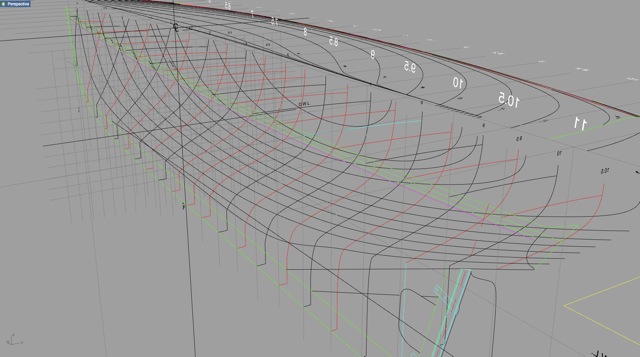

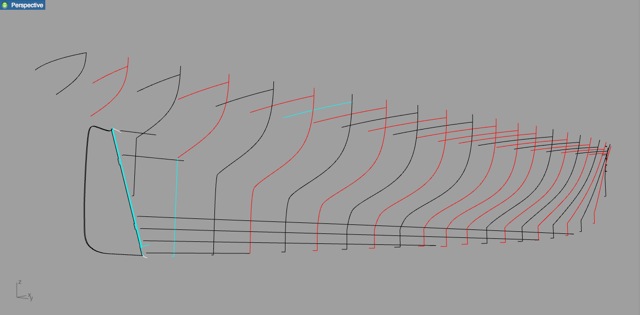

I

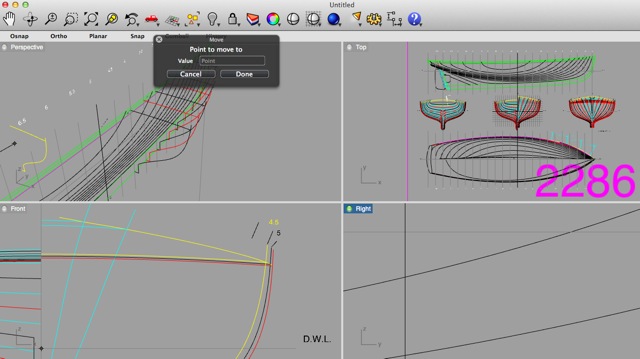

basically selected the lines one by one from the flat CAD file, rotated them

into alignment with the appropriate axis, and moved them into position. Not being particularly Rhino savvy, it

took me a while to find a good method, but progressed well enough from there. It was painstaking work – I probably

put about eight hours into getting all the curves oriented correctly.

More

data is good right? Not this much

data. This process was satisfying,

but ultimately not very effective for creating a 3D model.

I

tried with just the transverse sections, without success. Rhino 5 for Mac Beta just did nothing,

while Rhino 4 for Windows (WM Fusion based) crashed with an out-of memory

message. It was only after asking

for help (once the storm cleared and people returned to MIT) that I realized

just how much data I had been asking my Macbook air

to deal with.

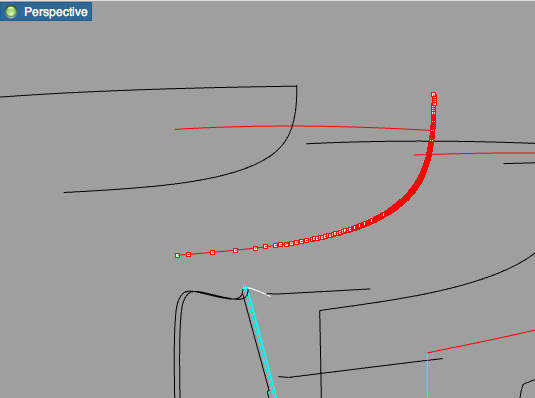

First Significant learning: The curves in the CAD files I

had imported have a lot of control points (thousands). This is a pretty quick way to stop your

system (well, my system).

So

the next step is to explode each curve, rebuild, and join them back together. Book shelf

looking more and more like a good idea.