For my 3D print I decided to do something that would tie into my final project, so I chose to make a wheel for a 1/5 scale RC tire I had lying around. I bought these tires last year because they have a "run flat" design and looked fairly realistic. Here is my attempt at making wheels/rims for these tires:

I wanted to make a wheel that can hold this tire through tension alone, like a real wheel does. To start I grabbed my trusty calipers, and took a bunch of measurements (which turns out is very hard to do on soft rubber). At this point I decided to try and 3D scan the wheel instead of measuring it, but this ended in failure since the scanner could not see into the tire. After getting what I hope are good measurements I procedded to make the 3D model.

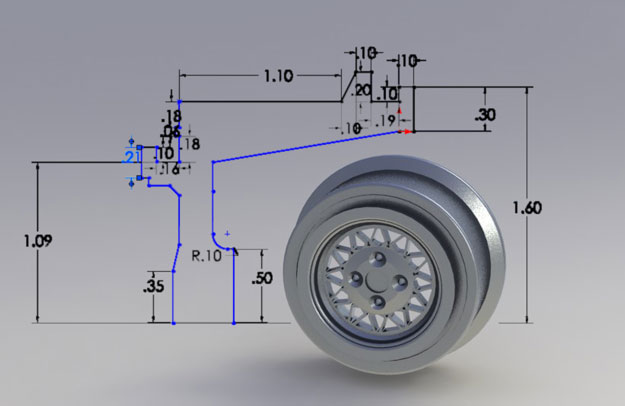

In the past I have used Maya for 3D design, but this time I decided to tackle SolidWorks, as it is obviously the better CAD tool. The work flow in SolidWorks is very different than Maya. After spending a few hours with the help files and various online tutorials I came up with the following model:

Notes from a Solidworks newb:

- There is a very helpful tool called hole wizard. It generates holes for any screw size/head type

- You must exit a sketch in order to do anything non sketch related

- If something won't move, check to make sure it is not over constrained

After that I simply exported the model as an .stl file, and sent it to the printer que.

I am still waiting on my print to come out of the dimension printer at the IDC, here it is in action:

This is what it looks like with the tire mounted on the wheel. I'm happy with the way it came out, it fits snuggly and rolls well.