WEEK 8

For this weeks assignment we had to make something big! To help us make something big we (the IDC shop group) got trained on the hobbyshop CNC, and it was a joy to work in a fully stocked shop. After orientation on Friday, I signed up to cut on Monday, but got delayed because of Sandy.

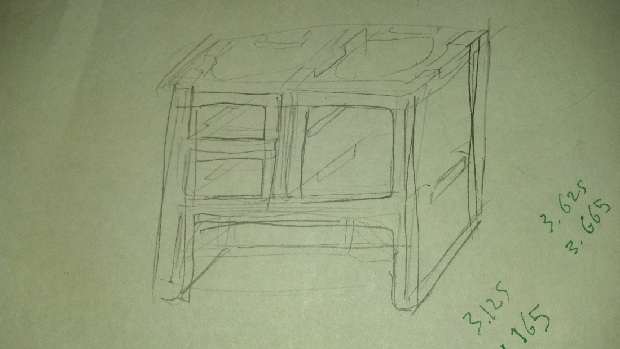

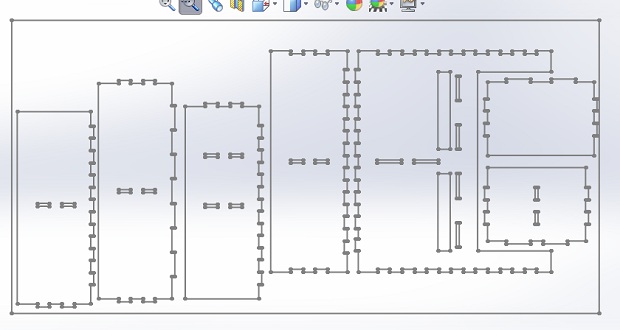

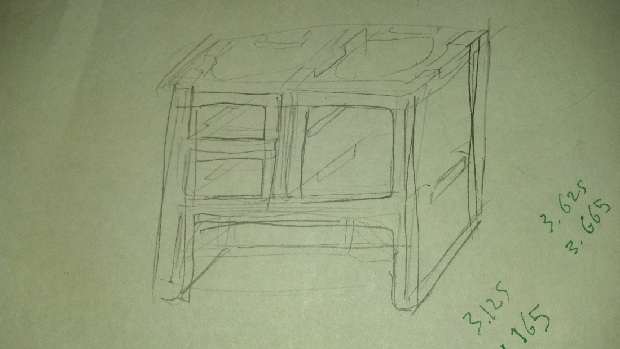

As something big I decided to finally re-make my 38 gallon fish tank stand (It was hastily made a few years ago out of scrap 2x4). This was my preliminary sketch

I measured the fish tank stand to be 36.25" long, and 12.5" wide. I decided to keep the same height, which was about 32".

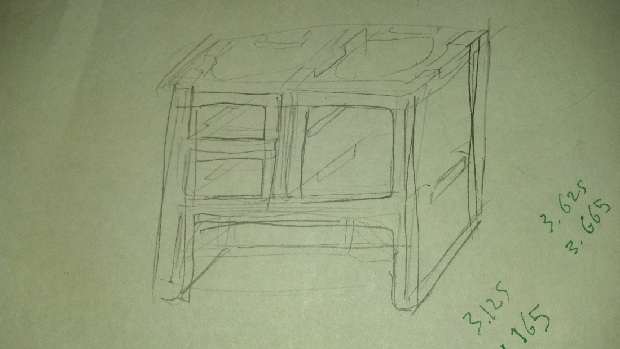

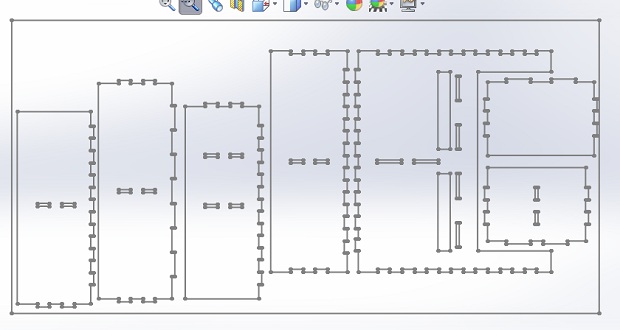

First step was to draw the 2D panels out in SolidWorks, TADA:

As you can see this particular fish stand can be made out of a single 4x8 foot piece of plywood.

As you can see this particular fish stand can be made out of a single 4x8 foot piece of plywood.

Next I exported my sketch as a .dxf, opened it in Rhinoceros, moved things around, and then finally saved the sketch as a Rhino file, and opened it in MasterCAM.

I used the following settings:

-Stock height = .48"

-Tool Diameter = .25"

-Feed rate/plunge rate = 100/50

Here are some shots of it cutting out the pieces

Once everything was cut, (about an hour of cutting) I went to quickly "press" assemble the stand. A nice trusty mallet helps alot!

Upon doing so I noticed that I forgot to add tabs for one of the shelves, so I quickly cut out another (I LOVE RAPID PROTOTYPING TOOLS!)

After cutting out the final (CORRECT) piece, I went about sanding, and then glueing the piece together. Here are some pictures of the super exciting process...

I am currently waiting for the glue to dry, but it stands on its own with friction (from the tabs) alone. I think I will make a "finished" version of this out of real plywood, as I would like this stand to look nice. I'll update this page in the following weeks once I buy my own giant 4x8 piece of plywood.

Back