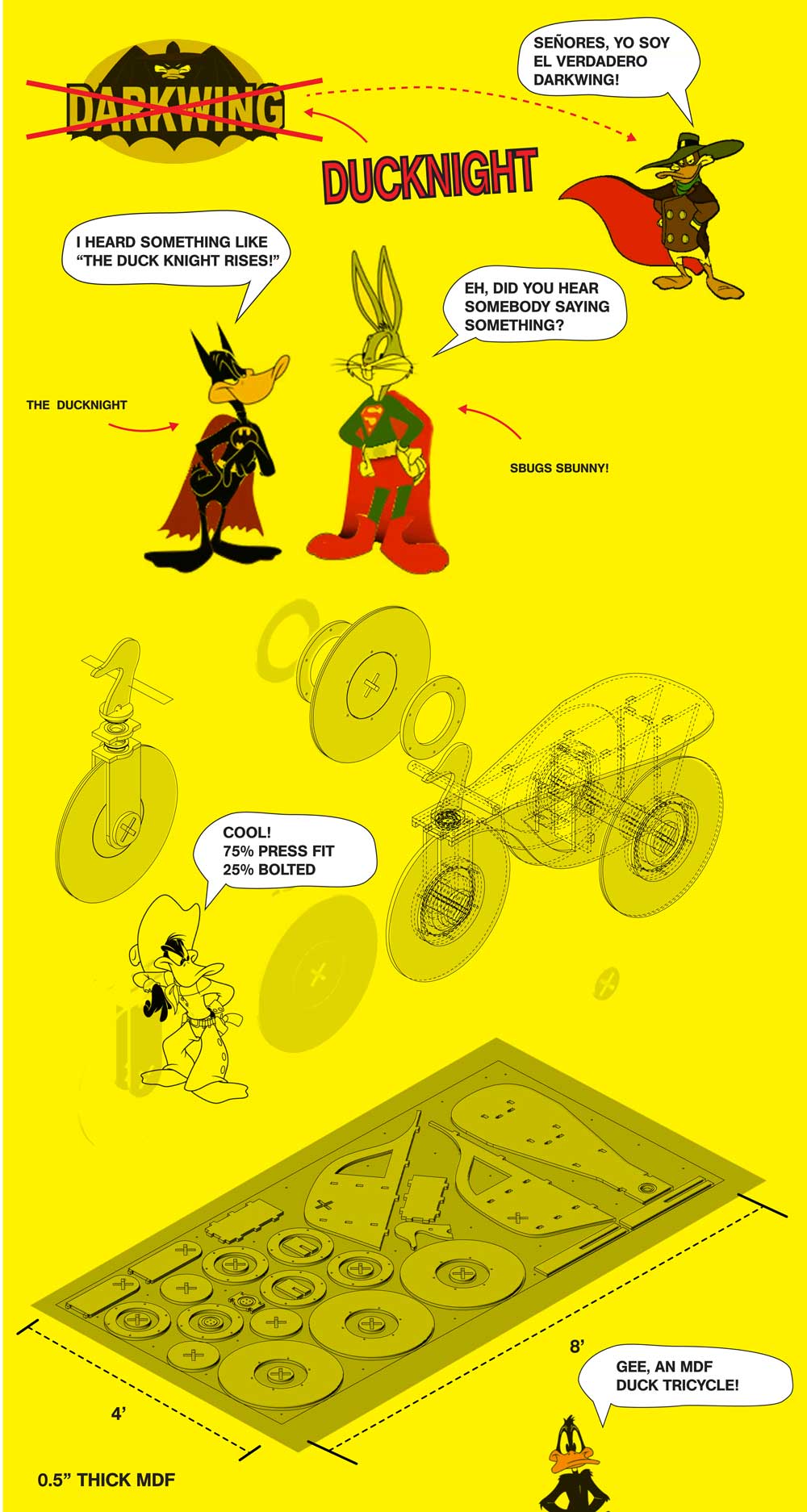

The Duck Knight Rises!

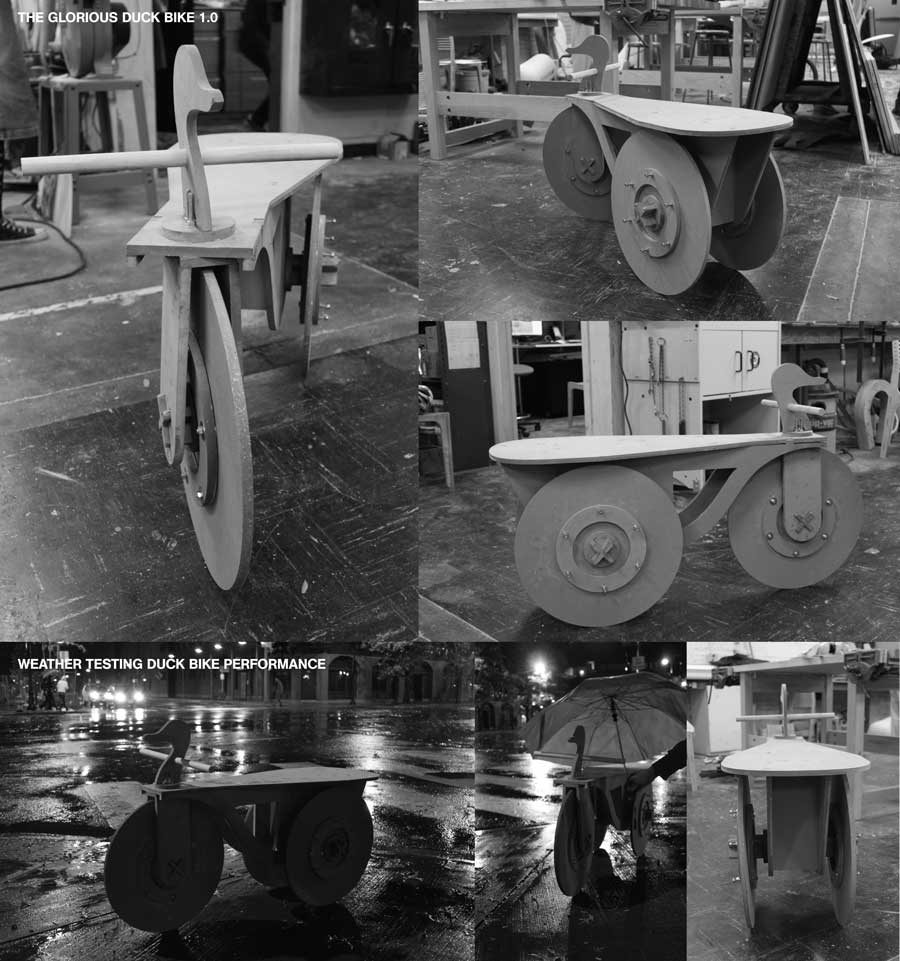

Long gone is the Darkwing era...be ready for the rise of the Duff, eh, DUCKNIGHT! Here is a brief glance on how his first Duck Bike prototype was made!

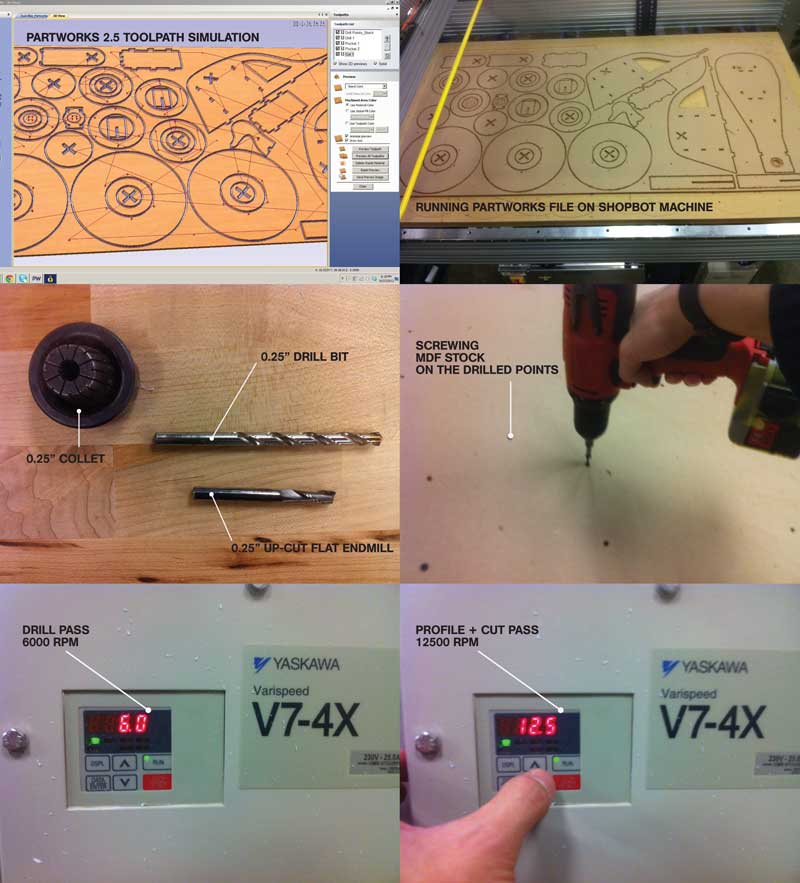

Cut File Setup + CNC Milling

The Duck Bike 1.0 is entirely made out of 0.5" x 4' x 8' MDF stock milled on the ShopBot at N51 Architecture Shop. I used PartWorks 2.5 to generate both the drill and cut paths with 0.25" drill or mill bit.

Here are the settings I used on the job:

DRILLING

0.25" Drill Bit

6000 rpm

1 inch/min

POCKETING + CUTTING

0.25" Up-Cut Endmill

12,500 rpm

2.5 inch/min

Material Processing

The CNC process itself took approximately 75 minutes excluding the time it took to place and to remove the material. As MDF is not the best material there is to cut, I spent most of my time sanding off the bad cut edges until they looked convincing and ready to assemble.

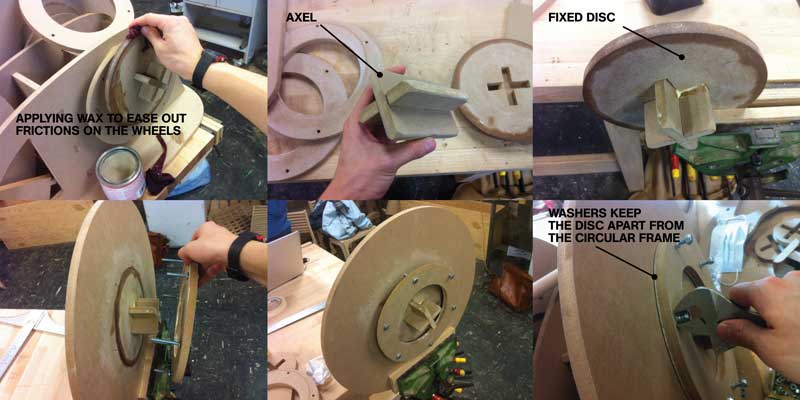

Tricycle Assembly

Just like in the previous programming exercises, I had to physically "debug" a lot of glitches. There are a few notes that I made during this process:

1. Always, always, and always give tolerances to allow pieces to fit together, especially if you do press fit construction, like I attempted here.

2. Never excessively force MDF pieces to snap together by hammering as this will, most likely, damage the structure of the component.

3. If you want surface with less friction, e.g. in the case of making spinning wheels, use the Varnish or Wax, but not Oil / Lubricants.

Wheel Assembly

James Coleman, one of the TAs helped me in developing this MDF wheels detail. The axel is made out of press-fit MDF boards and the actual wheel, sandwiched by two outer discs, rotates around a fixed disc that's glued in place.

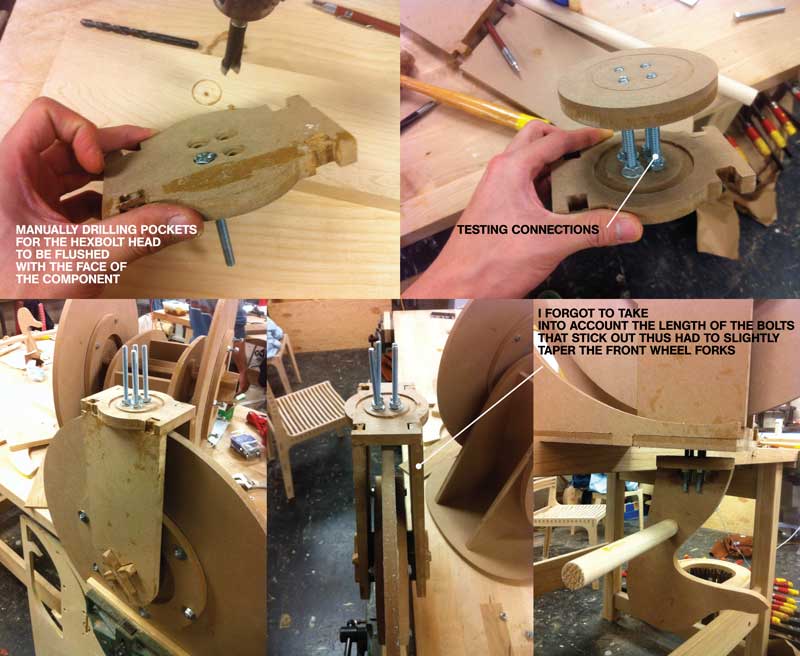

Steering Wheel Assembly

This, for me, was the most challenging part. I based the design of the steering wheel around the size of the Steel Thrust Needle-Roller Bearings that I ordered from McMaster-Carr. Well, unfortunately, this won't arrive on time as Hurricane Sandy postponed the UPS ground delivery.

As I highlighted above, I had to improvise to ensure that the bolts and nuts won't be stuck to the fork, and at the same time, ensuring that the parallel mechanism works. It works -- just not yet perfected! ;)

The Duck Bike Test Drive

Here it is fresh from the shop! Rolling on...Fun!

Duck Bike 1.0 Completed!

The Rise and Death of The Duck Bike!

After having way too much fun in the studio, the Duck Bike decided to surrender itself to the law of force; the MDF seat was way too thin to carry the weight of the knight. It's not glued, only press-fit, so it deformed and created a hinge point, and therefore broke into two parts!

Time for Duck Bike 2.0!