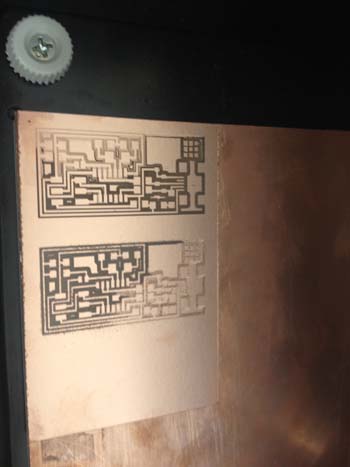

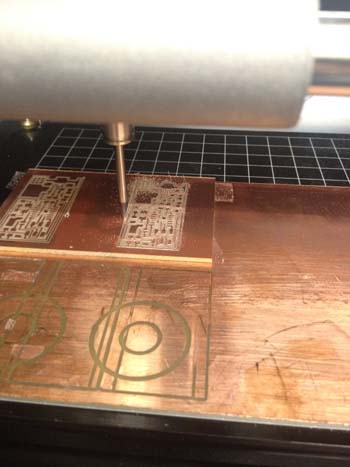

The modella is used to mill FR1, a paper based copper plate.

The process is explained in detail here.

Source Files:

I had issues from the start with milling because there was lefover tape on the modela surface. You can see that this resulting in the board bowing up in the center. At this small of a scale this is enough to cause major problems with the mill paths.

Soldering was not so bad since I have done it many times in the past. The major difficulty was that the components were surface mount style which means very small. The pins on the USB connector surface were very tiny.

MicrocontrollerCrystal

USB connector

ribbon connector

Zener diode

jumper

To make a FabISB, you need to program it the first time with another FabISP or equivalent. Connect the new FabISP to the old FabISP and the both into the computer. The new FabISP is just using the computer for power.

Install:

firmware.zip

In the terminal:

USB power

make clean

make hex

(sudo)

make fuse (check programmer in Makefile, may need to repeat)

(sudo) make program

Once it's done

desolder SJ1 and SJ2

make IDC ISP cable, connecting header pin 1 to pin 1

Then the microcontroller can be programmed from a computer.