Task

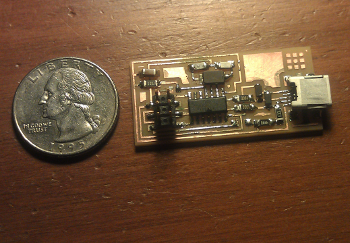

Make the FabISP in-circuit programmer.

- Roland MODELA Milling Machine

- Fab Modules

- Soldering Iron

- Soldering Tools: solder, copper braid, tweezers

Approach

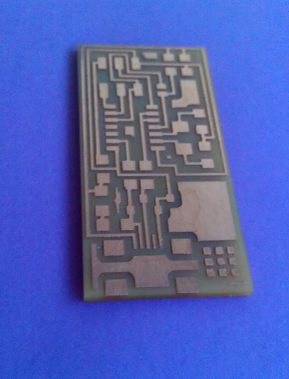

Milling the board

We used the Roland Modela milling machine with a 1/64th and 1/32 endmills to create the board from FR1 paper based copper plates from the trace and interior files provided. The steps in this process were:

- Prepare milling machine: brush off dust and find the most level area of the bed on which to mill the plates.

- Prepare the plates: place double sided tape on the back of the plate to fix it to the bed. Make sure the tape surface is smooth and even--don't use dusty tape, watch for air bubbles, and do not double layer tape at any point!

- Fix the plate to the bed: align edge for a square cut. Smooth plate down to ensure a flat surface.

- Translate files: use the Fab Modules to translate the png files to files readable by the Roland Modela. Begin with the traces file.

- Calibrate location (xy): Use the Fab module xy settings to find the lower left hand edge of the plate. Take note of these co-ordinates.

- Cut traces: find the 1/64th endmill to cut the traces with. The tip should "sparkle" when spun, otherwise it may be broken.

- Calibrate height (z): place the endmill in the machine. Use the alan key to evenly loosen use screws and insert endmill. Tighten screws. Use the Fab modules to center machine on cutting area. Adjust the height through the arrow buttons on the machine so the endmill falls slightly above the plate. Loose screws again and careful bring endmill in contact with plate. Do not let the endmill fall! Tighten screws evenly while holding endmill and pressing down slightly.

- Verify the z-calibration: use the Fab modules to move to another xy region of the plate. Ensure that the endmill continues to be in contact with the plate. Adjust endmill height as necessary.

- Adjust the settings: to cut the traces begin from the traces default in the Fab Modules. Adjust the z depth from -0.1 to -0.12 for slightly more cut depth. If the endmill is new or very worn, adjust the speed from 4.0 to 3.5. Remake files as needed.

- Cut traces: send file to the Modela and wait awhile! Don't forget safety goggles in case the endmill tip breaks.

- Cut out the board: following the above procedures, replace the 1/64 endmill with a 1/32 endmill and use the "interior" file to cut out the board. Do not move the board or turn off the machine between cutting the traces and the board. Use the cutting defaults in the fab modules, set the xy position to match the values used for the traces, and adjust the speed downward as needed. Z-depth may be adjusted from -1.7 to -1.9 for a deeper cut.

- Finish the board: remove the board carefully using a blunt metal edge (ex: butterknife). Clean the board by removing double sided tape, using a ruler or sandpaper to level off copper trace edges, and washing board with soap and water (or Windex) to remove oils.

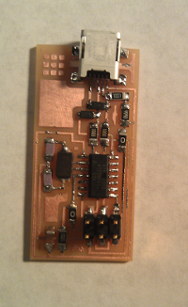

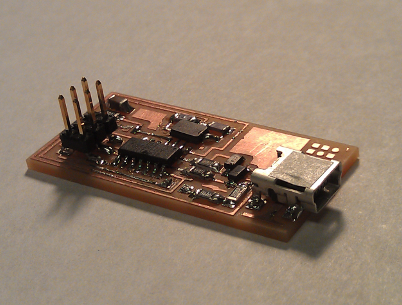

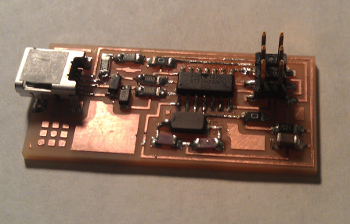

Stuffing the board

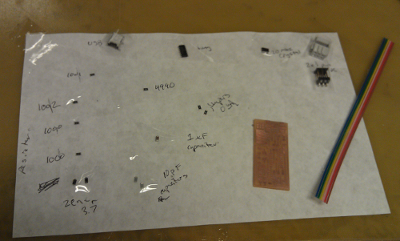

- Gather the components: following the schematic, gather the parts to be soldered to the board. As you go, tape them to a piece of paper and label them (thanks for the tip Dan Novy!). You'll really regret skipping this step.

- Make the IDC ISP cable: you'll use this to connect board to each other. Apply vertical pressure to the ribbon connector headers to get a solid connection through the wire casing. Set it up to connect header pin 1 to pin 1--the headers should either face each other or away from each other--not in the same direction!

- Solder components to the board: starting from the inside out and low to high, solder the components to the board. Anchor down one leg of the component with the other legs else aligned--this will hold the component in place as you solder it. You can remove any excess solder at the end.

- Soldering tips: use the flux pen liberally. The copper braid allows you to solder a whole set of legs at ones, then remove the solder in-between (i.e. get rid of the bridges); have the soldering iron fairly horizontal while you're doing this. Tweezers help when dealing with tiny components. The solder should be smooth and shiny looking at the end, otherwise it won't conduct as well.

- Program board: use a programmed board and your computer to program your board.

- Remove jumpers: once you've programmed the board, prepare it for use by desoldering the two jumpers. To do this, use tweezers to hold up the board by the jumper and use the soldering iron to heat up one end of the jumper. This should allow you to pull one end off and make it easy to remove the other side.

- Wash board: if you touched the board a lot while fighting with components, gently wipe it down to increase its longevity.

Trials and Tribulations

I started with a newer endmill and the cut turned out a bit jagged even thought I reduced the speed to 3.5. Gently sanding it down smoothed it out quite a bit. If it seems like the Modela isn't responding, make sure you're not in View mode.

Soldering these small components took some patience. A magnifying glass helped me to identify bridges and other issues. I also burned myself frequently--especially when removing solder--though I think my heat tolerance increased in the process. It was a bit difficult to juggle all the various tools while soldering though I think more practice will increase my ambidexterity and make life easier.