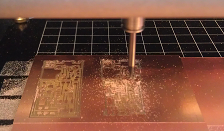

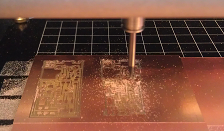

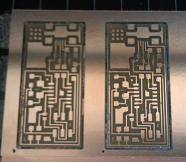

This is my favourite assignment to date, as I can now say "I've milled my own PCB". The hardest part of this assignment was getting the traces properly milled. The biggest challenge was getting the bed to be flat so that the end mill would mill evenly on the copper. We tried increasing the depth of the milling to 0.03 mm but still had a large surface taht was untouched by the bit. After trying to move the X,Y position to use a different part of the sacrificial layer, we gave up and just replace the bottom layer entirely. This was a success!

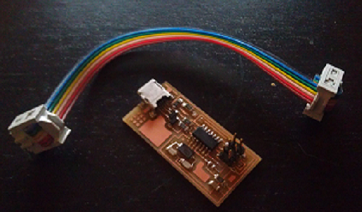

My very first self-made PCB!

I didn't realize how nice this mill worked until I was at a nearby school and showed this to a student in a mechanical prototyping class and got a compliment on my "nice looking board".

Populating the board was fairly uneventful as was the programming. Several people had issues because the microprocessor was out of sync with the external osciallator or had the wrong capacitor on the board. I got to learn about it as a third-party, which is fine with me.