I've made a shovel this week, with a linen/epoxy composite coating on the shovel blade to make it stronger. The shovel is made out of wood, a natural composite.

I started off with a fundamental misunderstanding -- I though you could make a very thick resin/fiber vacuum-bagged composite. Actually, the point of the vacuum is to squish it down to a thin shell, and the exothermic epoxy reaction means that a very thick chunk of this composite is not practical. Some composites (e.g. reinforced concrete, adobe, etc.) can be molded into thick parts. But many composites (like fiberglass, carbonfiber, etc.) are like glorified paper mache, and the point is to have a strong thin layer. The paper mache analogy helped me wrap my mind around composites. I had thought composites were completely new to me, but I've done paper mache before -- here's a paper mache No. 2 pencil I made after a year of multiple Econ Scantron tests a week:

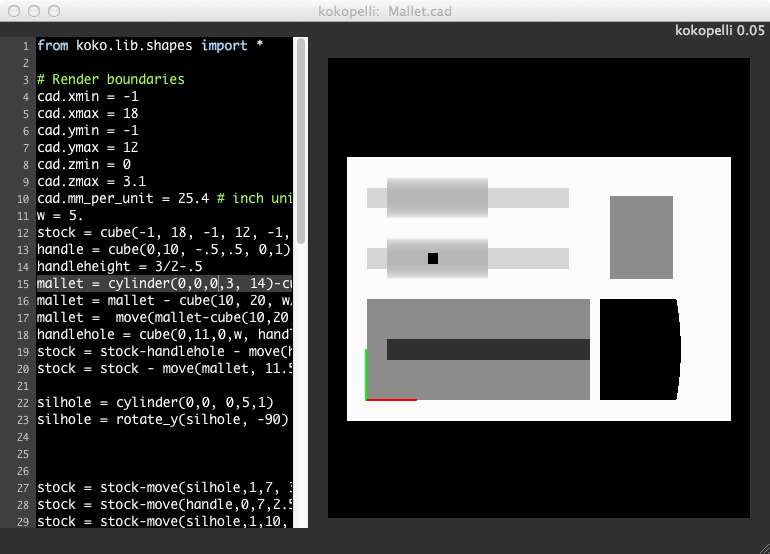

At first, I wanted to make a ladder, and then a mallet, which I designed a mold for. But I really wanted to try the vacuum bag composites, so this wound up not making sense -- in theory I could have made a shell of the mold for a light-weight mallet, or made a foam-core mallet, but this sort of defeats the purpose of a mallet, which should be heavy. Here's my original .cad design for the mallet mold, including a 2-piece mold to make a silicon handle:

After we realized my misunderstanding, Ken from the Hobby Shop gave me a nice piece of white pine, and taught me how to carve from it. I decided to make a trowel. First I drew the cross-sections I wanted with pencil:

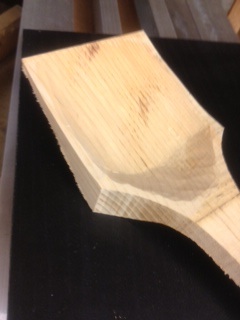

Then I drilled curves near the handle and cut the cross-sections out on the bandsaw. Machining white pine smells wonderful, and it started to look sort of like a shovel:

Next, I carved it and sanded it:

Here's what the sanded wooden shovel looked like. And wood is a natural composite, so that's sort of cool.

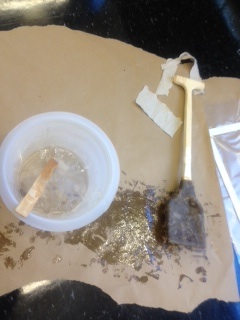

To strengthen the shovel blade, I added epoxy-soaked linen in strips:

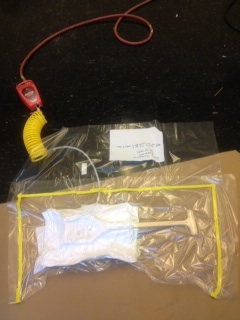

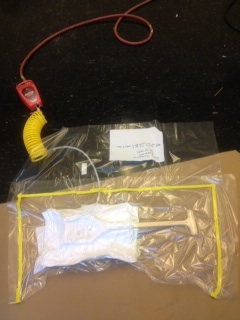

Then I hooked up the compresser to the shop air -> vacuum adapter, and made a vacuum bag for my shovel. I left it in the vacuum bag wrapped in bleeder and breather for 15 hrs in order to create a nice strong thin layer:

Here's how it turned out. In future, I would use a thinner coat of linen-soaked epoxy, and be very careful that it was tightly applied. It's definitely strong, but a little wrinkled and thick:

I'm adding polyurethane so the wood looks nicer:

I wound up doing three coats, sanding after the second one when I noticed some bits that needed sanding. Here's the finished product, from different angles: