3D SCANNING AND PRINTING

After Neil's lecture on 3D scanning and printing, I was really excited by 123D Catch, an app

from Autodesk for iPhone, iPad, and PC that allowed you to take your own series of photos

that the would be stitched together using a cloud service to create a 3D model. I made

two different models: one of a plushie turtle and another of a golf ball decision maker

paperweight. The program asks you to take 20-40 pictures 360 degrees around the object with

a couple of constraints. The object and the background that you're take the pictures against

should not be shiny and should have some variation or randomness on the surface. The app

had a little difficulty "creating" the series of shiny ball bearings at the base of the

golf ball so they came out flat and warped instead of having their own shape. The 3D model

also seems to be more like a 3D surface because if you flip the model upside down, you can

see the reverse shape of your object underneath. It's also best to use a circular table or

something similar as a base so that you take equidistant shots from the object.

If you're happy with your 3D scan, you can export your model (in the PC app) to an .obj format

file. From there, you can download 123D Beta to help convert your .obj file to a .stl

(stereolithography format file) to send directly to the 3D printer. I had trouble getting it

export as an .obj file so since I was running out of time to meet the Sunday 6 p.m. deadline

for a 3D print file submission, I quickly modeled a cup that I would hopefully be able to use

later.

The MakerBot Blog is a great resource about 3D printing and scanning. Their support staff

will write different tutorials and articles about neat tools to help you create better

and faster. For example, an article

from earlier this year talked about Autodesk 123D Catch, the iPhone app that I used

to 3D scan my turtle plushie. Another useful tutorial

shows you how to clean up your 3D scans for a better 3D print.

The $40,000 3D scanner in the FabLab did not seem to work particularly well. After watching

our TA struggle to get through the 14 different calibration movements, the scanner finally

produced...a bunch of surfaces that were unable to be interpolated. 123D Catch seems to be

doing a better job so hopefully, I can get that working soon!

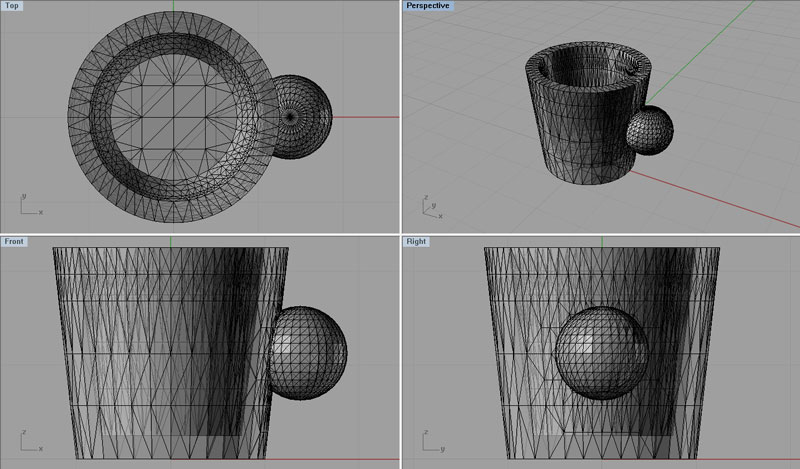

After modeling the cup in Rhino, I exported it as a .stl file using the option:

[ ] Ascii 784Kb

Opening up the .stl in Rhino, the cup became a series of triangulations that approximates

the curved shape of the original cup.

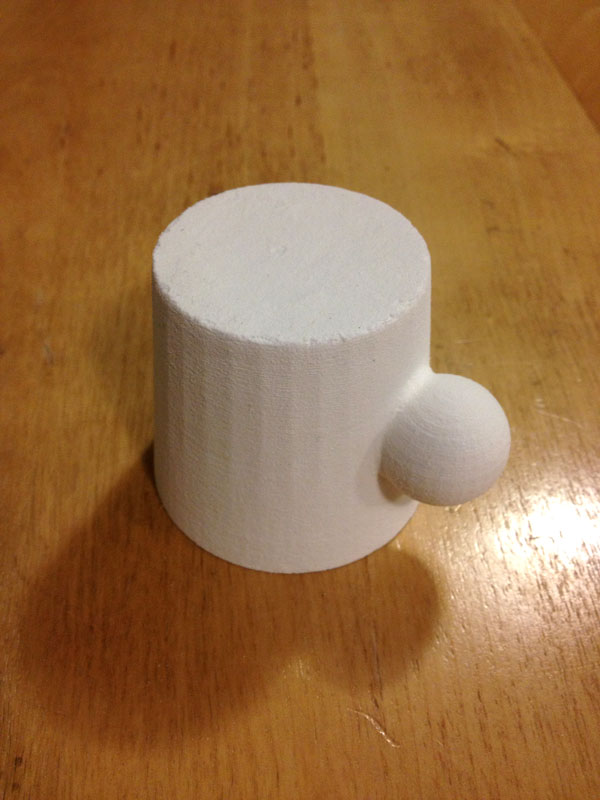

In the 3D printed cup, you can still see the triangulation of the original shape especially

on the ball-shaped handle; however, the inside was very smooth so I'm not sure how the 3D

printer processes the triangulations as it prints. The walls are quite thick, but the cup

survived the excavation process!!

Next step for the cup: a layer of super glue (and maybe something else?!?) so that I can

use it without breaking it!