fabisp

I had a bunch of trouble this week milling my board. My big takeaway from this is to not use the Modela when you are in a rush or tired since it is easy to make silly mistakes.

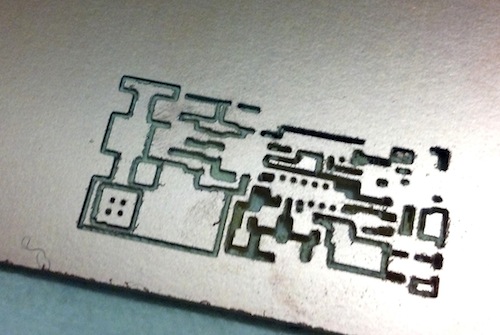

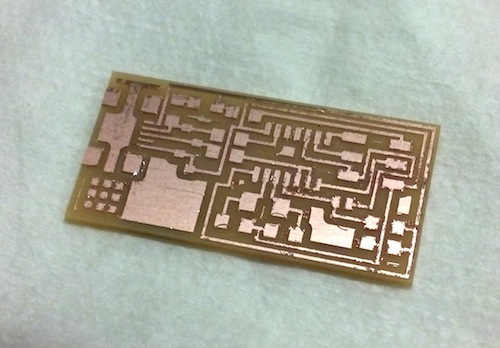

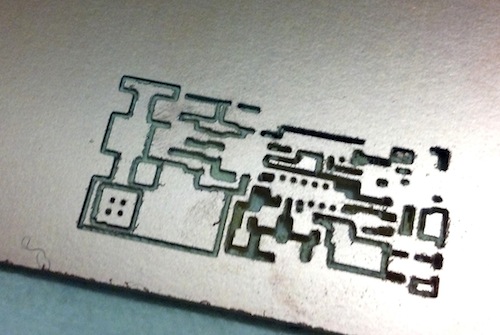

The first mistake I made was to try to mill my board when I didn't really have enough time before the person signed up after me. I think this one would have turned out fine had I not used the "cut board" setting when I was really supposed to be milling traces!

The second time I tried, I milled the traces without much problem. But when I loaded the bit for cutting out the board, I put it in too low and it snapped off when I switched from view mode to the normal mode! After loading a new bit, the machine actually was no longer lined up at my origin. I tried to get it to line up anyways, but it didn't work and I cut off some of the traces.

The third try, I think that when I snapped the bit, it may have bowed the surface I was milling on. I tried milling the traces twice, but it was not milling deep enough in the back right corner. I decided to take a break from this and come back when I had a lot of time and quiet so as not to feel rushed.

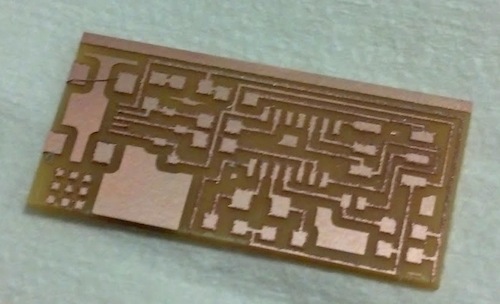

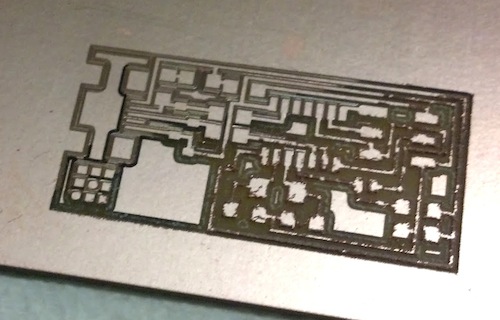

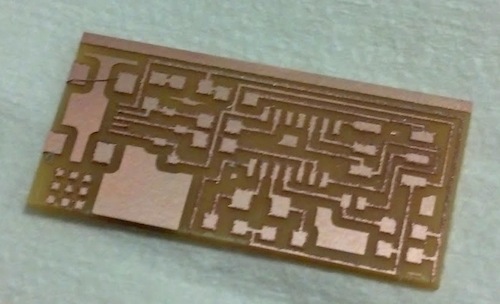

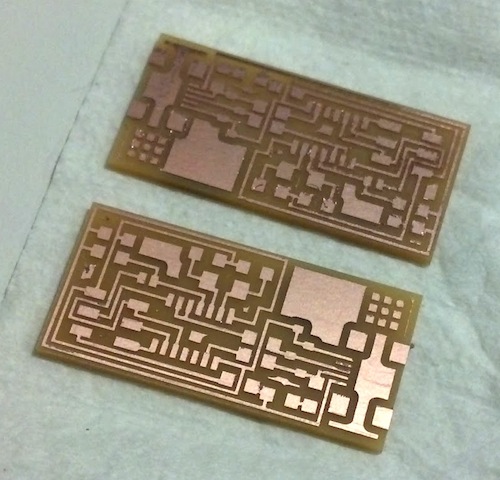

4th time worked! I think because I made so many mistakes and had to do this so many times I actually feel much less intimidated by doing this sort of thing, which is one of my goals in taking this class. Had this worked on the first try, I think I'd still feel nervous using this machine on my own.

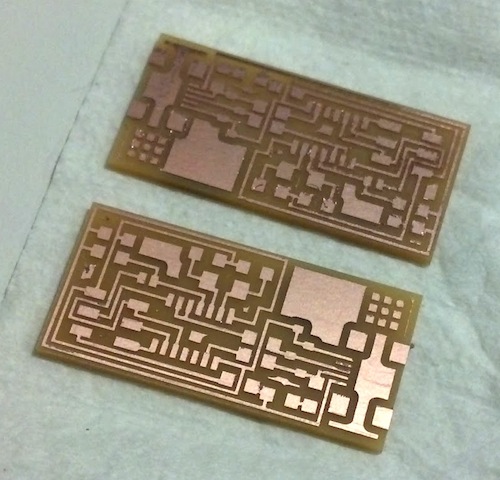

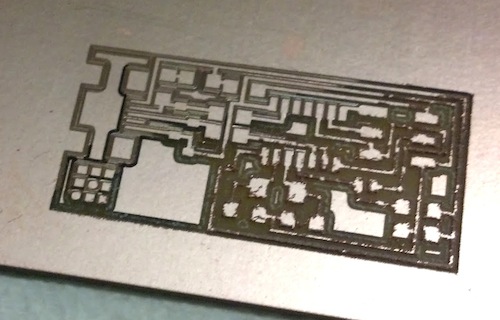

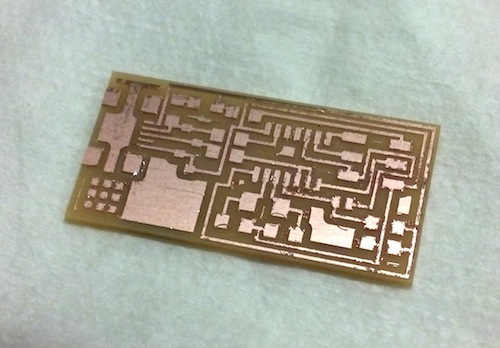

I think the mill I used on this last board was a bit older so there was some burring. I carefully used the spatula to scrape most of them off and used my fingernails for the rest, which worked pretty well. I decided to make a second board just in case. I changed the mill to a new one, and it came out much cleaner.

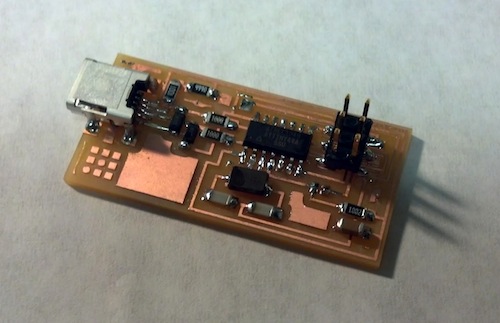

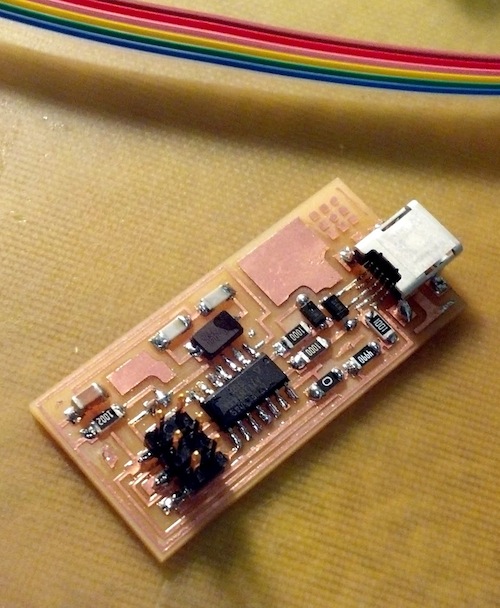

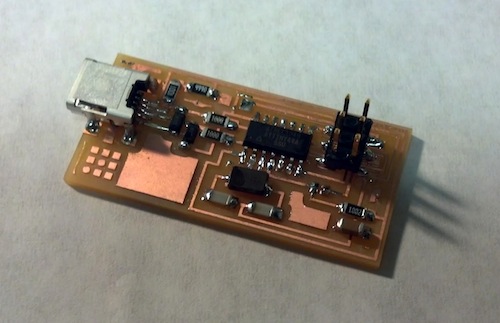

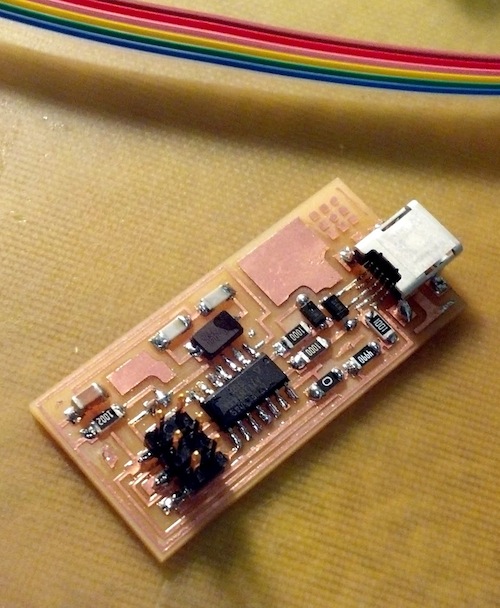

This was my first time soldering, so I had some trouble at first. In particular, I had a tough time putting on the USB connector because of the tiny pins. I soldered it on slightly misaligned and had already soldered the feet, so it was very hard to get off and do over! Eventually we used a heat gun to get the entire piece to come off, which was okay only because I didn't have many other components on the board yet. Once I got the USB connector on, everything went much more smoothly and I finished pretty quickly. Using lots of flux and tacking down one end of the component to keep it from moving before soldering the rest was key. I also found it helped me to tape the board to the table with a small piece of double sided tape. It was easy to pick up and turn it and then stick it back down.

I was able to successfully program my board, but I couldn't get it to program any others. I'm unsure why that is!