Week 10 - Composites

This week I made a bow using epoxy resin composite material.

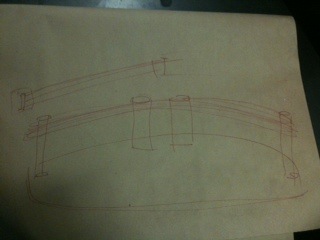

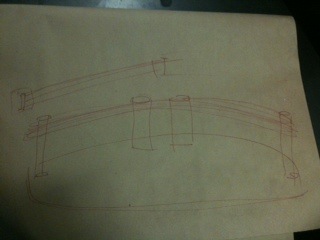

First I made a rough outline of a bow. Since the shape was very simple, I used the chain-saw in stead of shop bot.

I was happy with the smooth finish of the chain-saw.

I initially thought that a crease or resting place for the arrow would be useful.

I followed Kenny's vacuum bag technique.

I wanted to have the limbs of the bow to change shape and then return to original position after the arrow is strung. Kenny suggested that I use sisal twines wrapped around four posts to store the energy. However, I followed a simpler approach of wrapping the linen around the foam core.

Equal proportion of 105 Epoxy resin and 205 hardener were mixed in a cup. It took me almost 45 minutes to apply the resin-hardener mix to the tiny strips of linen and then wrap the linen around the bow shape.

Then the bag was sealed and vacuum pump was applied.

After 12 hours, the bow looked adequately cured from outside.

Without much hassle, I extracted the bow from the vacuum bag.

I drilled two holes at the corner of the two limbs for the bow-string (made of rubber-band).

I cut and bent a metal wire for creating the arrow, and then padded it with packaging foam, so that it cannot create much damage.