WEEK 3: ELECTRONICS

PRODUCTION

This week we started diving into the amazing world of electronics. The

idea was to fabricate an in-circuit programmer, using the provided circuit

configuration and component list.

Cutting the board

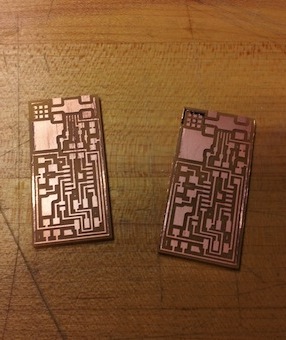

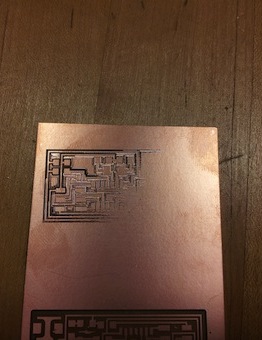

Not trusting too much my soldering skills, I decided to cut two boards

using the modela in the cba

fablab. I started using 0.12mm as the depth of cut

for my first board, but I was not very successful (chech

picture below). I changed the setting to 0.15 and worked pretty nicely.

Soldering

components

The tiny size of the components did not make

this process easy at all. At first, their size pushed me to use the magnifying

glass to get a better view at the circuit, but I soon realized that I was

loosing the parallax of my two eyes and was having problems to locate the

soldering iron in place. That«s why I decided not to use the lens. For the

couple of times I screwed a connection, I found a desoldering

gadget that was very useful (see picture below).

Programming

the programmer

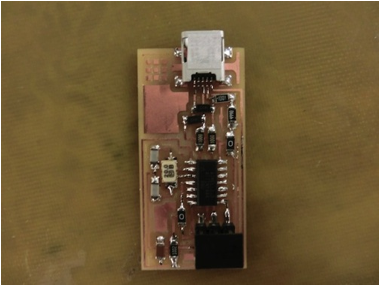

The board was ready to be programmed. I

downloaded the firmware files and, with the help of Dan Novy«s

ISP, I was able to program successfully my board.

* The picture above shows the wrong oscillator in

place (mental note: never trust what laboratory plastic bins say they have)

Last but not least, I desoldered

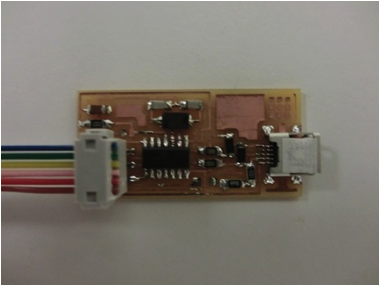

the 0k resistors of the circuit and made an IDC ISP cable. This is the final

result: