WEEK

7: MOLDING AND CASTING

Time for molding and

casting. I would like to share again Jared«s diagram, as I love how neatly he

explains what is this all about:

I really wanted to do a two

part mold, to start getting familiar with the idea of casting pipes and

registration points. I got some inspiration from the movie ÒInceptionÓ (great

movie by the way) and decided to mold and cast the totem like figure that is

central to the plot of the movie.

Using SketchUp«s

library I found a totem, and then added the registration points and casting

pipe. I used cones as registration points, as I was told by

Leigh that cylinder s don«t work too well.

I created a surface to divide the two parts

of the mold and saved both parts as separate stl«s.

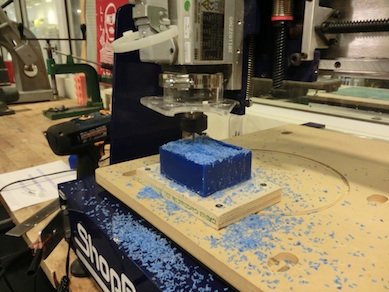

I used the desktop shopbot

to machine the wax. The software used was: Partworks

3D for the pass rough/finish configuration and Shopbot

3 for running the machine. A small detail that was not milled as expected: the

mold on the left shows a canal between walls and the piece in the bottom.

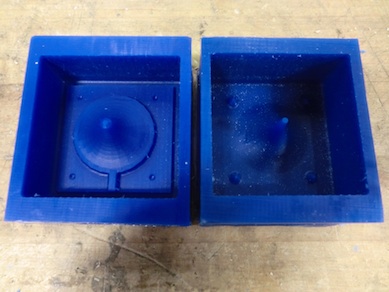

Geoff Duval helped me with the casting

process. We used oomoo to create the intermediate

mold. We also used some acrylics and weights to keep the surfaces flat (just in

case we needed to uniformly apply pressure in the last casting step):

Geoff and I tried to cast urethane. Two

problems I encountered: 1) The casting pipe was not big enough to let the air

escape 2) The urethane cures super rapidly, so by the time we had filled Geoff«s

mold, the mix was not liquid enough to fill my two part mold. In a desperate

move, I opened the mold and tried to cast both parts separately. It was ok for

one, too late for the other (as seen in the right picture below).

I also tried to cast hydrostone

in order to get the complete part. The final result (wax mold, oomoo mold, urethane half part, hydrostone

complete part):