Moulding and Casting

Inspiration

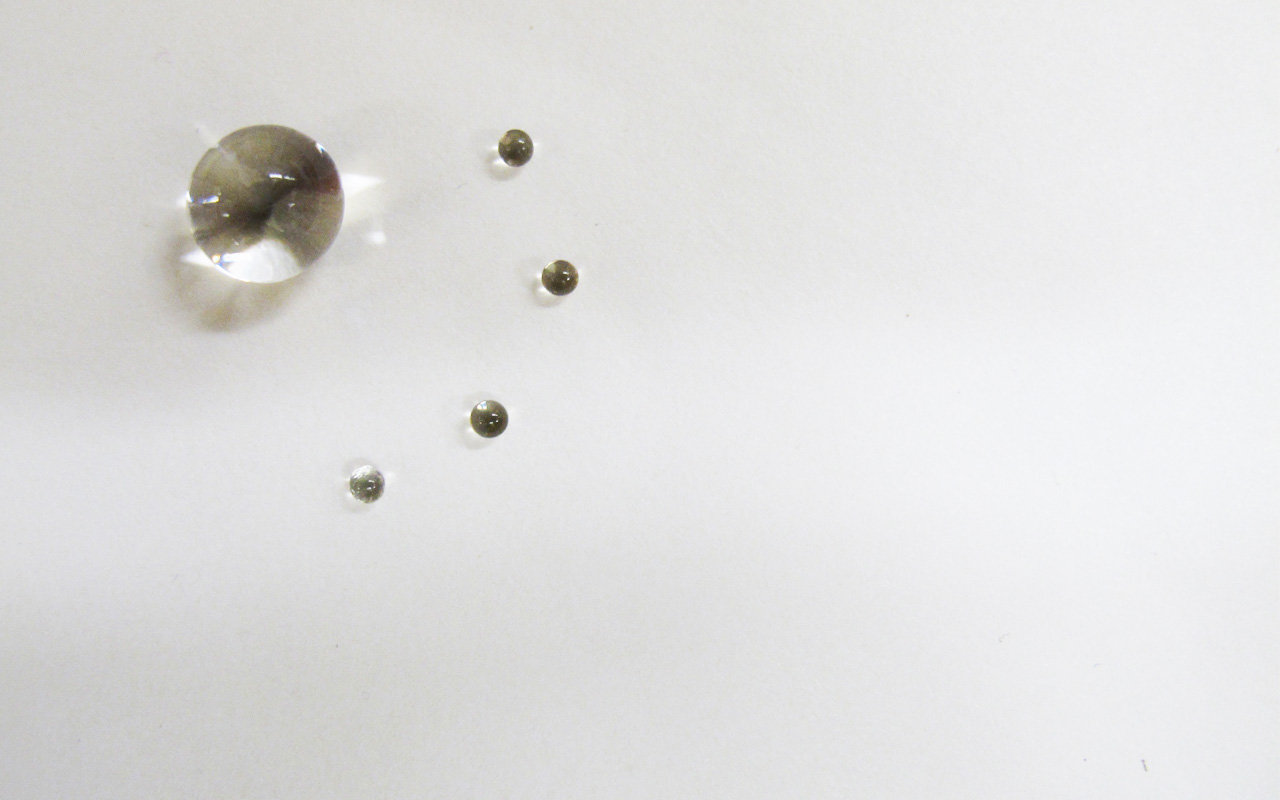

I had some water beads for a studio project, and they gave me an idea for moulding and casting. Water beads are gels that expand once in water. Compare the original size with the expanded one!

For the 3d printing week I made a cheese by booleaning spheres from a shape. These water beads could be the analogue spheres for me to boolean out of a casting and moulding process. What is more interesting is that I can vary the number, density, and size of the spheres to create porosity. Here are some more expanded water beads with texture.

Conceptual Design

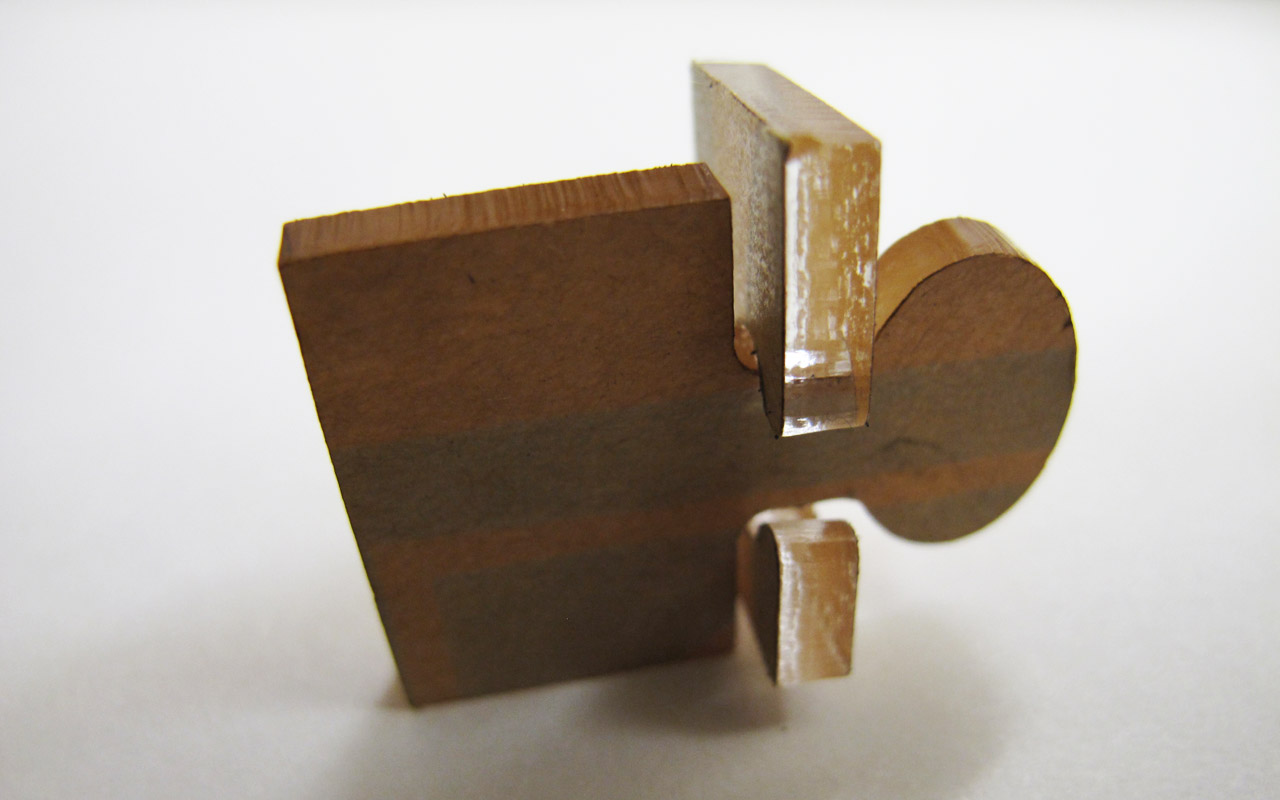

I tested a joint system where you twist and then lock. Here is a mock up of that with plexi.

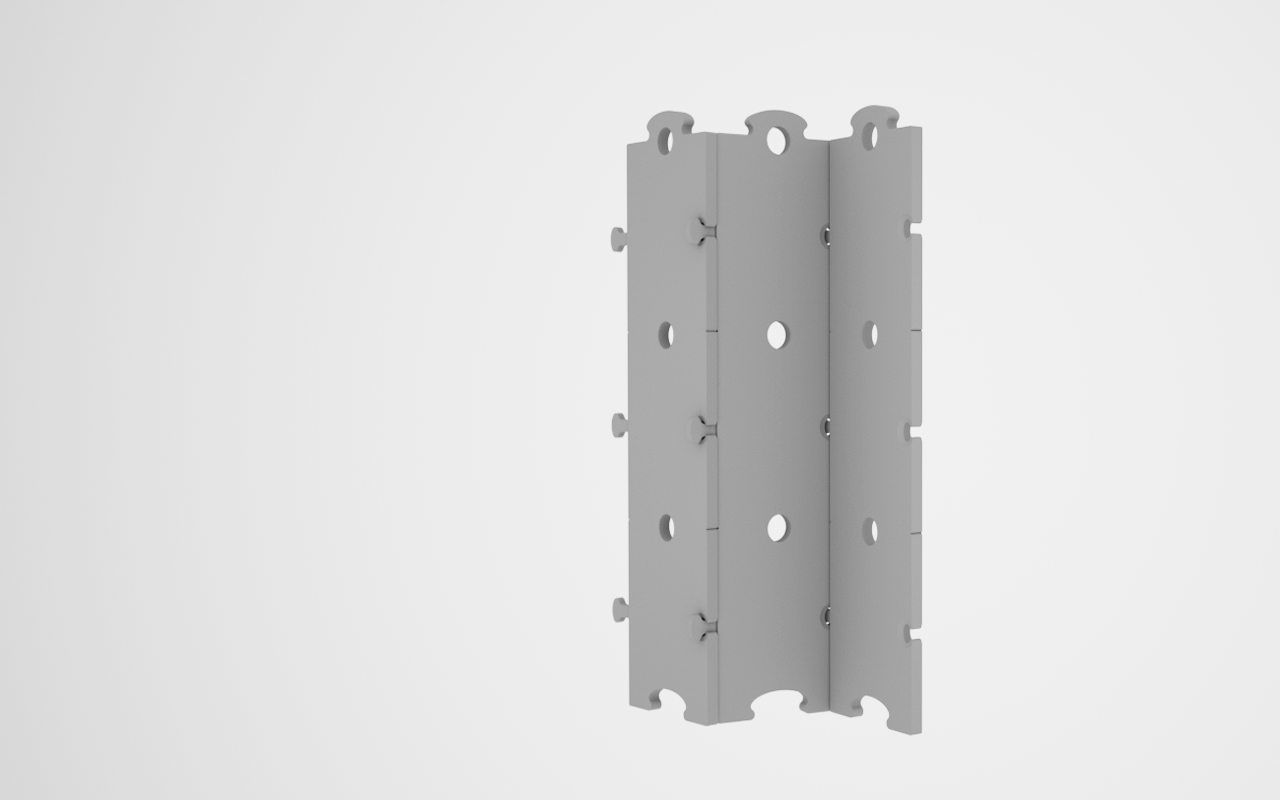

Here is what it might looks like, slotted together and without porosity.

Pre-Fabrication

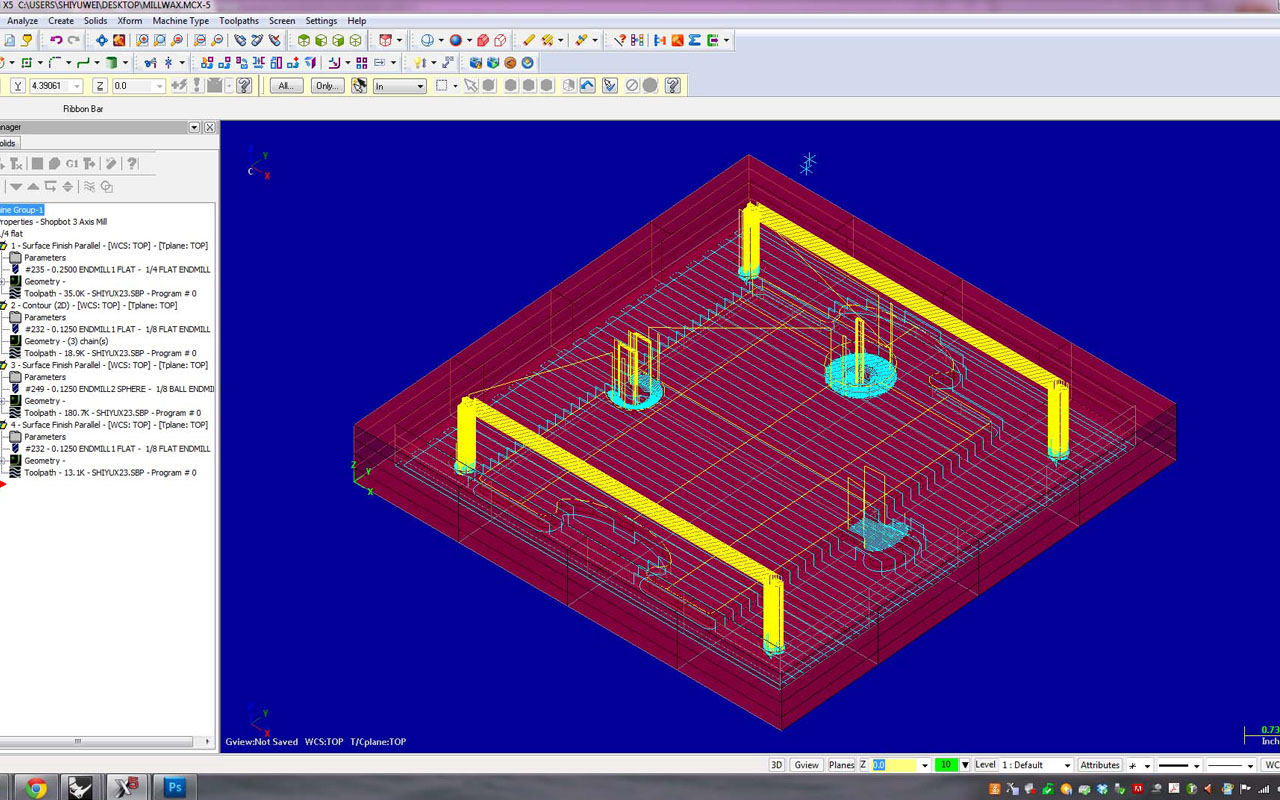

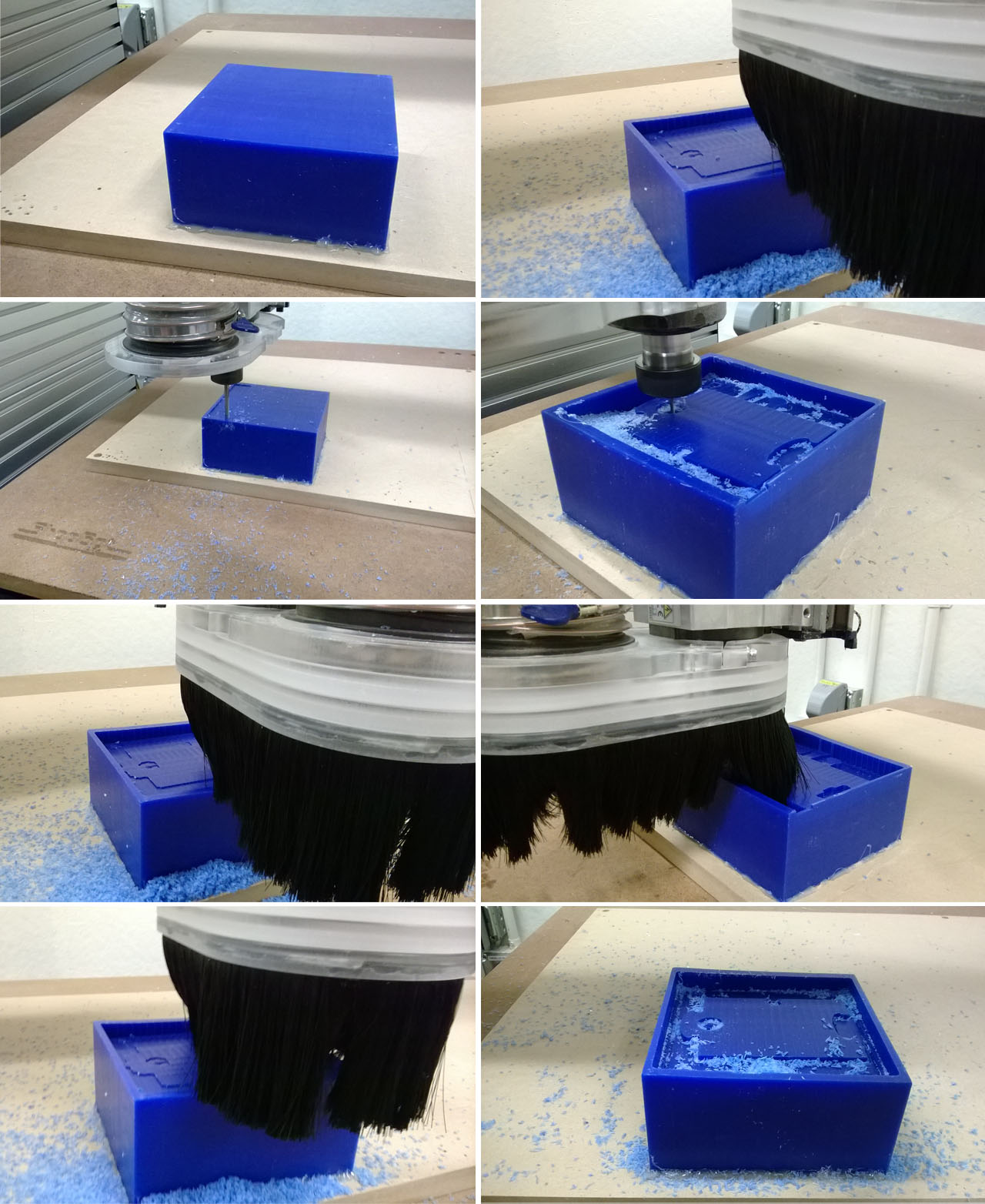

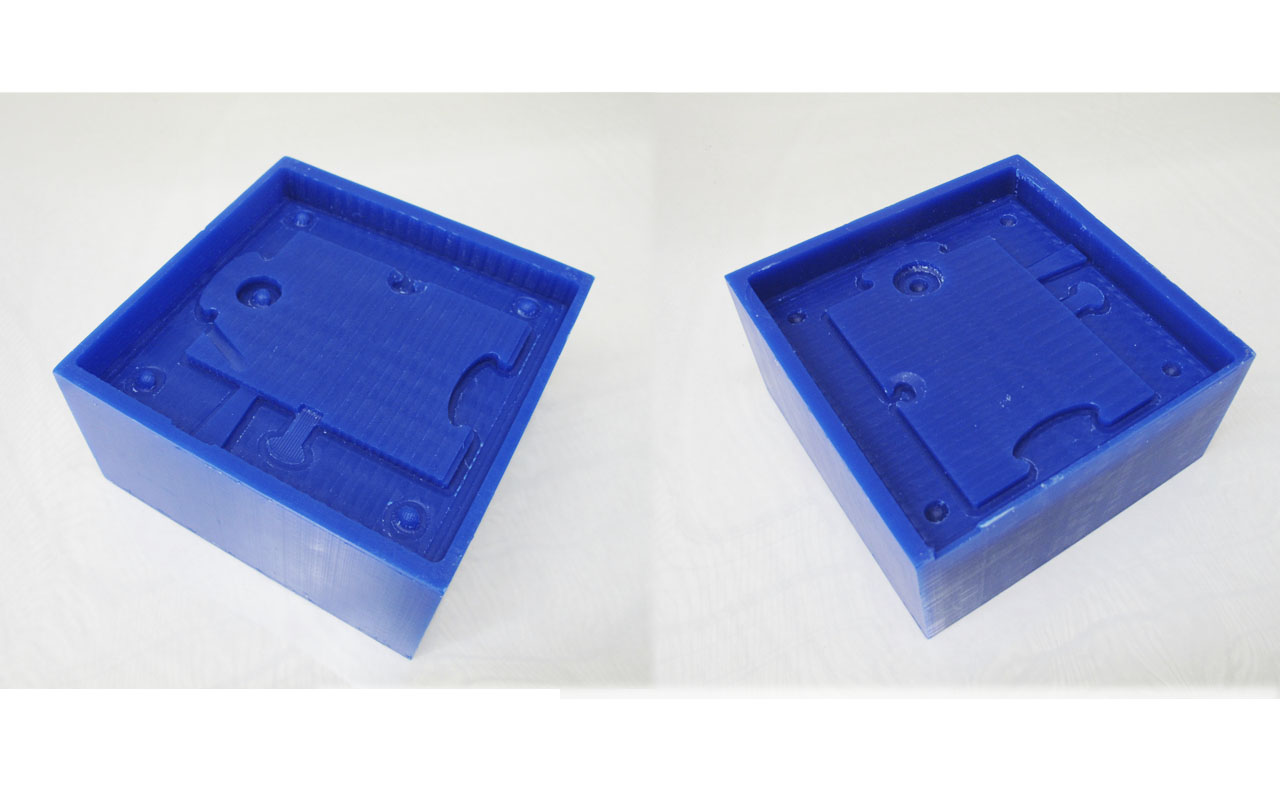

I used MasterCam to set up the milling file. A couple of things learned - to make sure a surface is not accidentally taken; you can do "check surface" to pretect it.

Milling process... At the late hour of the night I forgot that you had to redo the z-zero after a tool change. Needless to say... yeah.

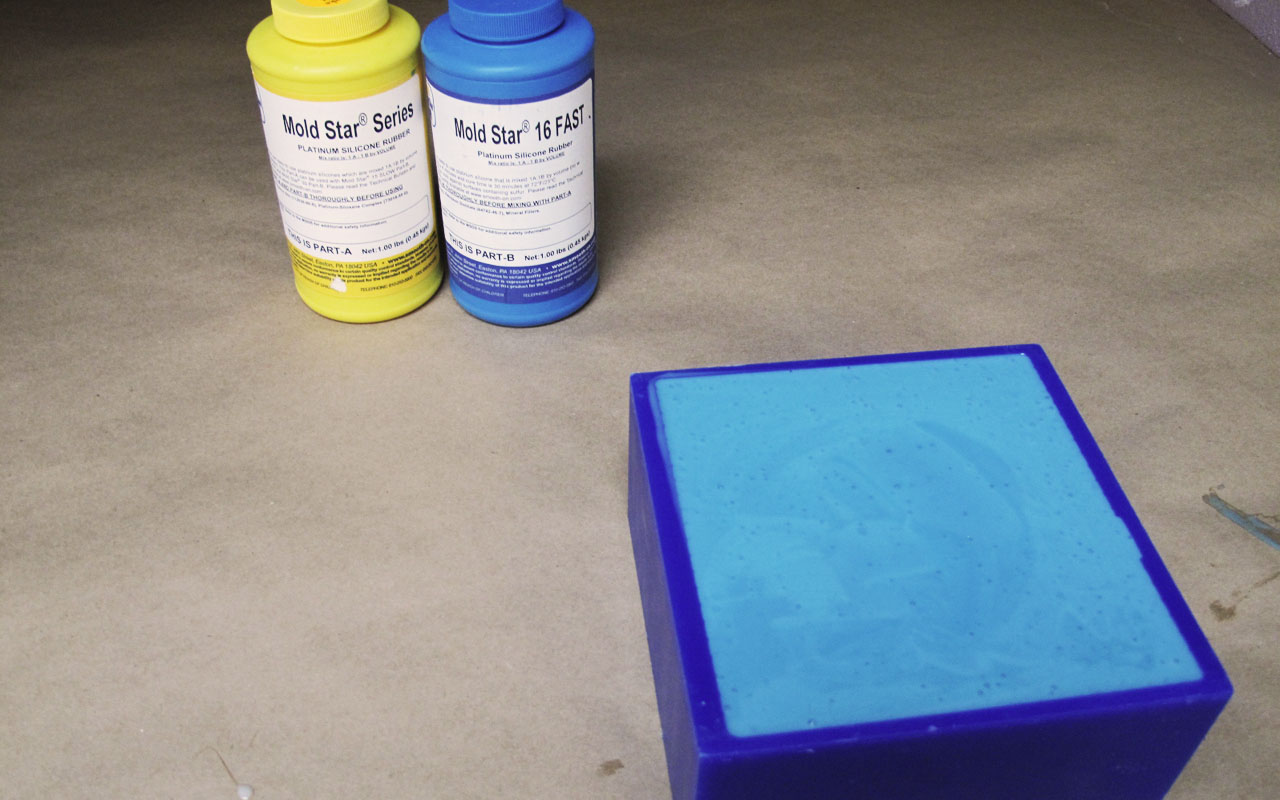

Casting

I used Moldstar 16, which cures in about 30 minutes. I had some left over from 2 years ago and decided to use that instead of waiting 4 hours. I mixed the two-part solution, which was very thick, and then let it cure for about 40 minutes.

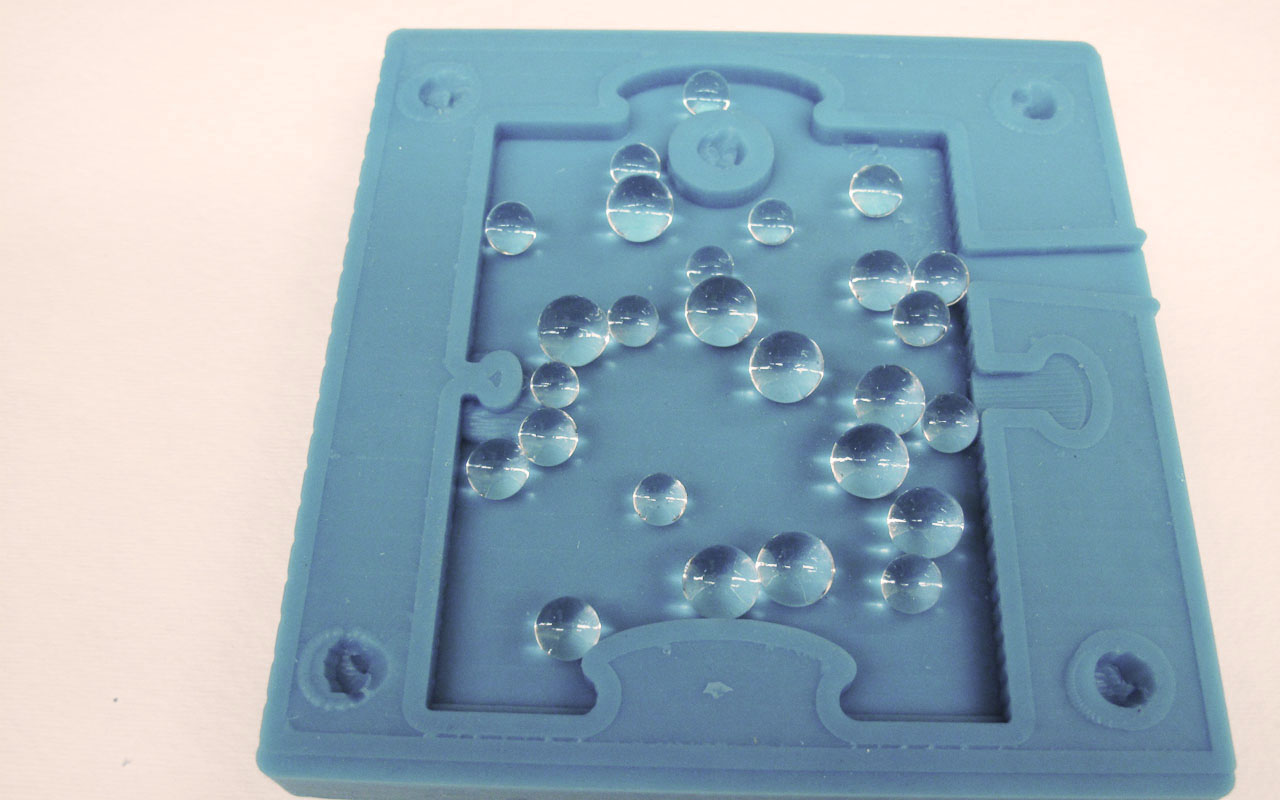

After the silicon dried, I took them off of the wax and them added the water beads to the moulds before closing.

I sealed the two parts with hot glue to prevent leakage, then I used two books as backings to hold the moulds rigid. Of course when I started pouring I covered the books up. This is just a demonstration.

Here is the cast piece. Unfortunately the water beads all clumped together at the bottom; and the moisture in them made the resin dry slower (or not dry at all).