This assignment started like a complete disaster. I failed in almost every step of the way and that's not fun. Having said that, I did learn a lot and hey, isn't that what's it all about?

Let's begin, this week we needed to create something big using either the ShopBot or the Waterjet. I wanted to build a rocking chair - sounds easy right? Well apparently not. After about 10 hours of 3D modeling which ended at 4am I decided to build a rocking stool instead of a chair since I spent too much time designing only half of it and my time is short due to 3 simultaneous projects i'm currently working on. In class we were told that we'll have a full 3D axis machine to work with but in practice, due to machine time limitations, we could only use it for two dimensional shapes. My model was not made for that so I had to make some adjustments on the fly. This means that every round shape hole that I made now needs to be a rectangle or I somehow need to make the joints round. I choose the latter and carved my parts so they fit. This took a while and left me with two broken legs which I had to cut again. That leads me to my next mistake, some joints were a bit too thin - combine that with the Oriented Strand Board (OSB) that we had and you'll get broken parts. Since my design was made for full 3D machine I had to neglect parts which made my stool a bit shaky. The heaviest thing it can hold is my laptop which ended up being not a bad functional bathroom rocking stool ;)

Next time, I need to pay more attention to what tools we really use and their limitations and also stop making thin parts that break easily.

After I cut the parts I used sand paper to make it smooth and added glue to strengthen the pressed-fit joints.

The good part is that it works now and look somewhat similar to my design just without the nice surrounding curves. The process retrospectively was very fun. I have a new skill, I can cut almost anything and that will definitely come in handy. Looking forward to next week when we'll learn to design electronic circuits!

Important notes when working with the ShopBot:

- Make sure the surface and screws are flat

- When zeroing the X and Y axis the drill bit should be half on the material and half outside

- Watch your hands, this thing is no joke!

- Calibrate the Z axis using the metal plate

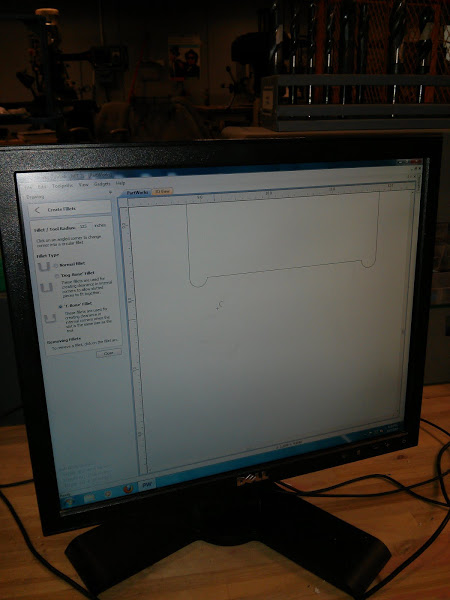

- When creating a tool path make sure there are no open curves and that the generated path is doing what you wanted

- Make room for the drill head by using the Fillet tool