How can you turn a weak foam into a super light rock solid?

The answer is Composites. The art of combining more than one material in order to make another. It's like programming, you create something new and at the end it looks like magic :)

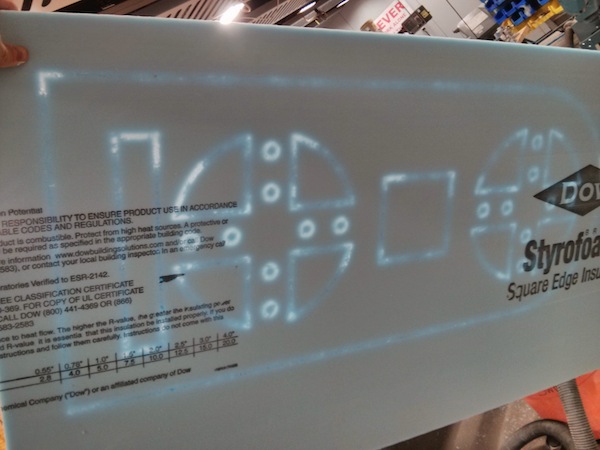

Since time is flying and soon we'll need to present our final projects, which by the way mine is going towards being a hovercraft, I decided to start building the hovercraft structure. Foam is super light, which makes it a great choice for lift power but its also super weak. That makes it a perfect choice for this week's assignment - make it strong while keeping its light characteristics.

Since I only need the bottom part rigid, I vacuumed the burlap with the epoxy and bleeder to the foam and left out the release sheet to make it stick. That turned out just perfect. Now I have a rigid bottom that might sustain hits from the ground.

Tips of the dayAfter learning to work with Partworks3D I forgot about the 2.5D one for models without 3D curves. Since i've used the wrong software I ended up wasting precious time - we all know how sucks that can be... On top of that I skipped the finishing toolpath since I didn't have anything that needed to be smoothed - but that left me with half an inch material at the bottom of my model which made removing the part stage longer than usual and leaving me with really rough ends. The better way to go is using the other software and leaving epsilon inch just to make sure the bit doesn't hit the sacrificial layer and breaks (since you're probably using a really fast speed if you cut foam).

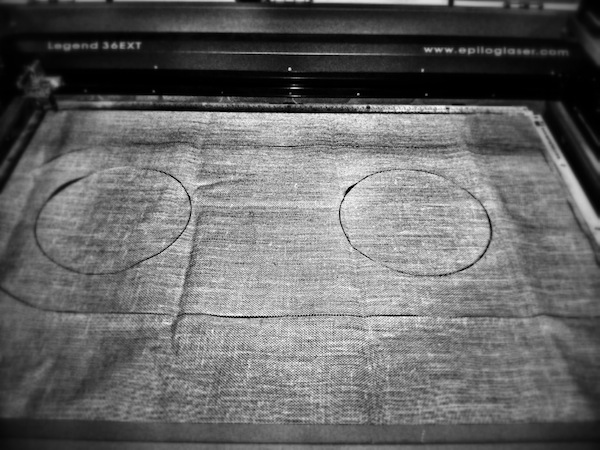

To save time I used the laser cutter to cut through the burlap. First I put a single layer at really high speed (90%) and low power (I think about 15%). Then I overlapped all remaining three layers and used a lower speed with a bit higher power. Nothing was burned and it did the job super quick :)

I wanted to fortify the bottom of my hovercraft so I used the vacuum method. When I turned the vacuum on, the bleeder moved a bit leaving small parts uncovered. That scared me a little but eventually nothing happened since I used the anti-stick spray. Good to know that it works :)