|

||||||||||||

| HOW TO MAKE (ALMOST) ANYTHING MIT MEDIA LAB |

|

PROJECTS | ABOUT | CONTACT | ||||||||

|

|

|||||||||||

| 3D PRINTING - week4 | ||||||||||||

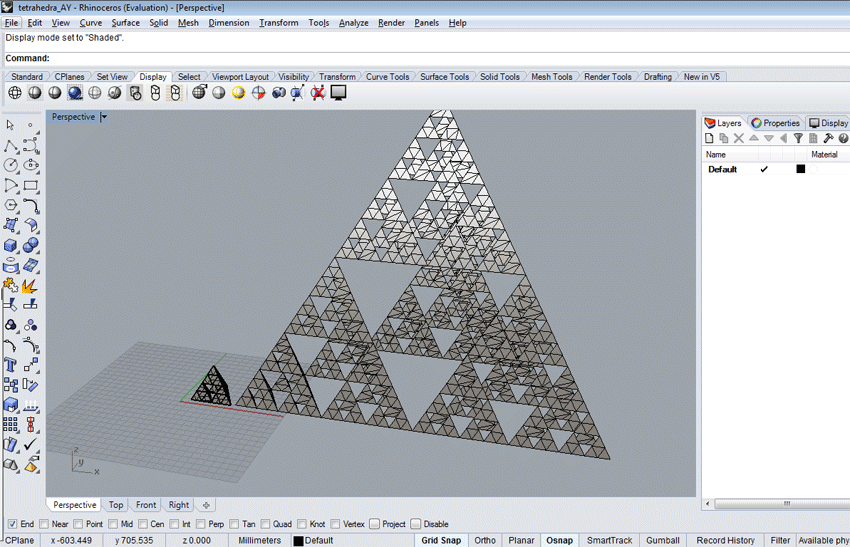

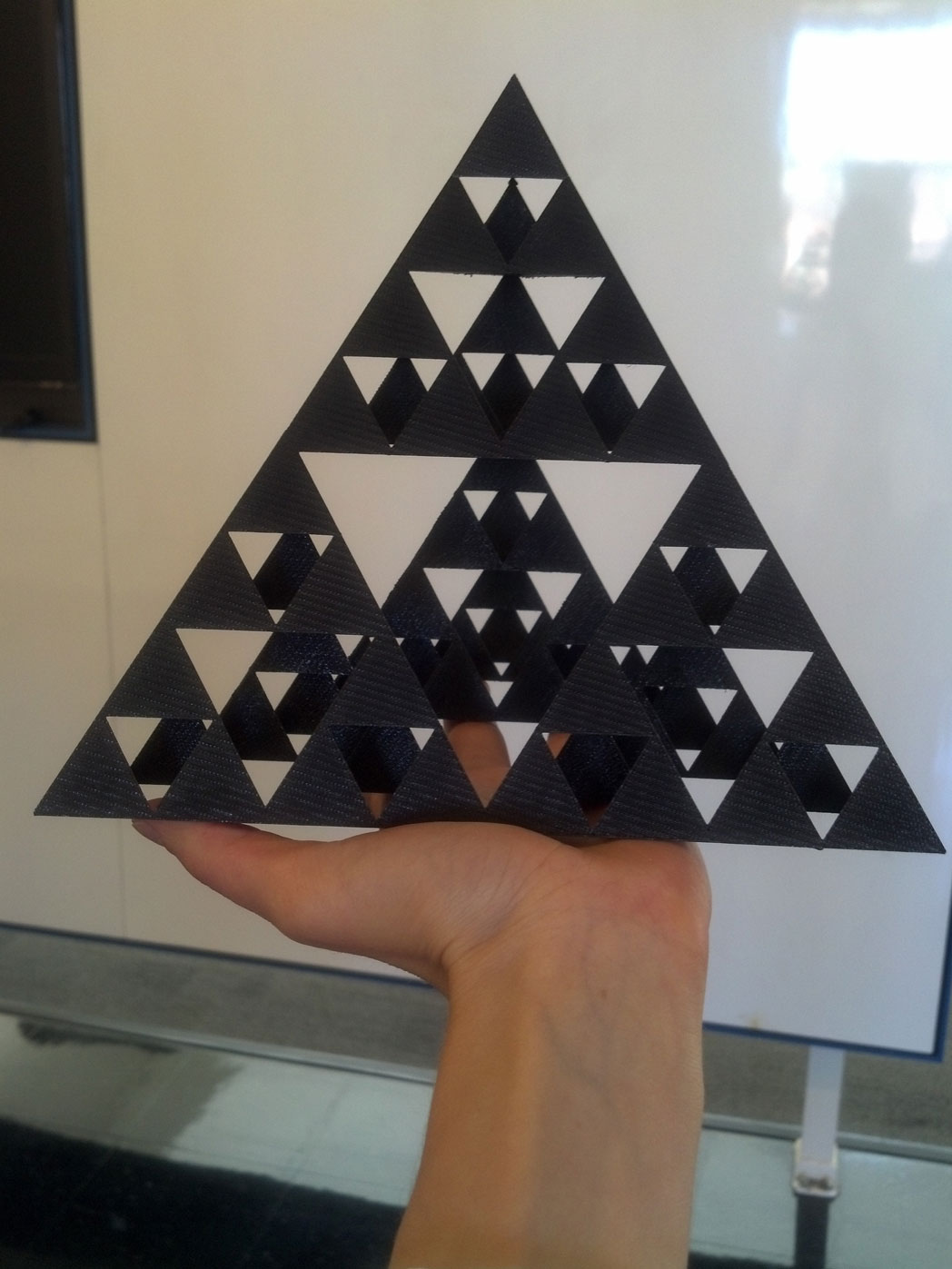

The plan was to make an epic tetrahedron that inside of it had fractal-like series of tetrahedrals. This was the idea: |

||||||||||||

|

||||||||||||

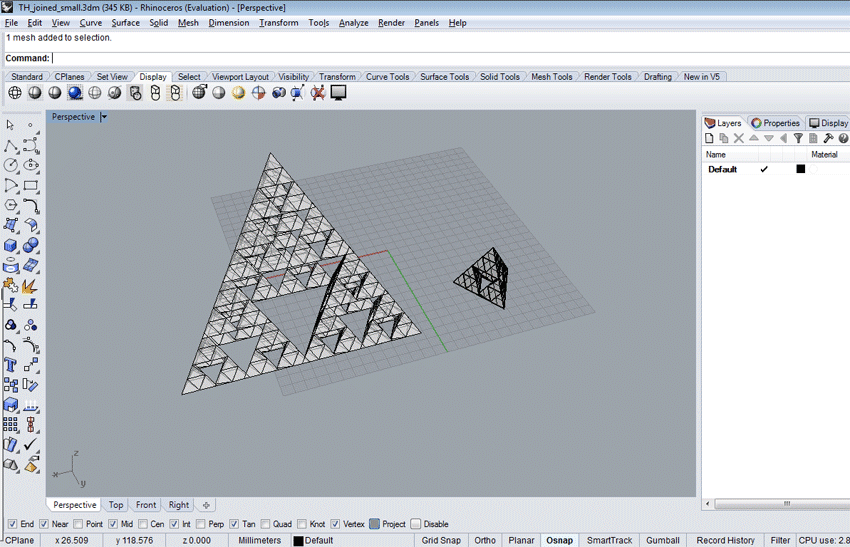

| Download the .stl mesh file here. Rhino was my preferred software, enjoyed immensely the extremely dry or extremely excited voices in tutorials online. I made one tetrahedron with the help of a box, and then used the copy (&translate) command, snapping to endpoints, to get all the other tetrahedra multiplied and aligned. The trouble, however, was that these lines are in themselves infinitessimally thin, and without some more substantial overlap these tetrahedra would not hold together. | ||||||||||||

| Software Problems | ||||||||||||

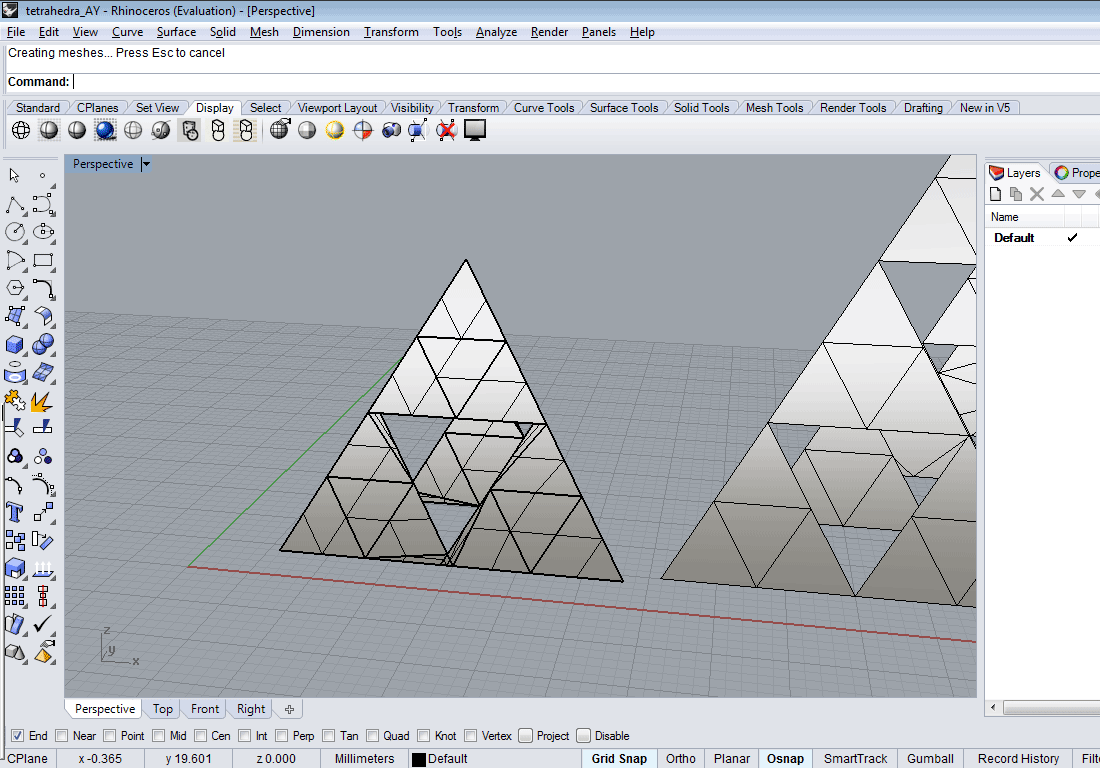

| What seemed like a trivial thing was actually very confusing - difference between surfaces and meshes, and in both cases how to make them into a single solid. Moreover, the difference between meshes and NURB surfaces, and why Rhino does what it does. It turns out that Rhino doesn't really like the name "solid," so the equivalent for it is a "closed polysurface." Also, while it can join meshes over and over again, it doesn't allow you to join closed polysurfaces to other polysurfaces. So, creating one solid tetrahedron from rotating and joining 5 triangles, and expecting it to simply form one whole solid with another tetrahedron just like that that intersects a bit on the edge - was an invalid command. Also, it turned out that - either from polysurfaces (created via first CreateSolid command) or from meshes - a single solid is created by *Boolean* Union, joining overlapping solids (found in the Mesh Tools / Solid Tools menu, the icon looks like two spheres intersecting), NOT by Join nor Intersect nor too many other methods I tried. Before applying that Boolean, the surfaces to be Joined must be closed. Moreover, it turned out that concerns about having one "solid" were unnecessary, since Makerbot needed the file in mesh form in order to print, not a "polysurface." Here is the final product. The intention behind the small tetrahedron was to make sure Makerbot understands a solid in the same way that I do, and that the connecting edges between separate tetrahedra would be thick enough for it to fall apart, but thin enough to preserve the aesthetic. | ||||||||||||

|

||||||||||||

|

||||||||||||

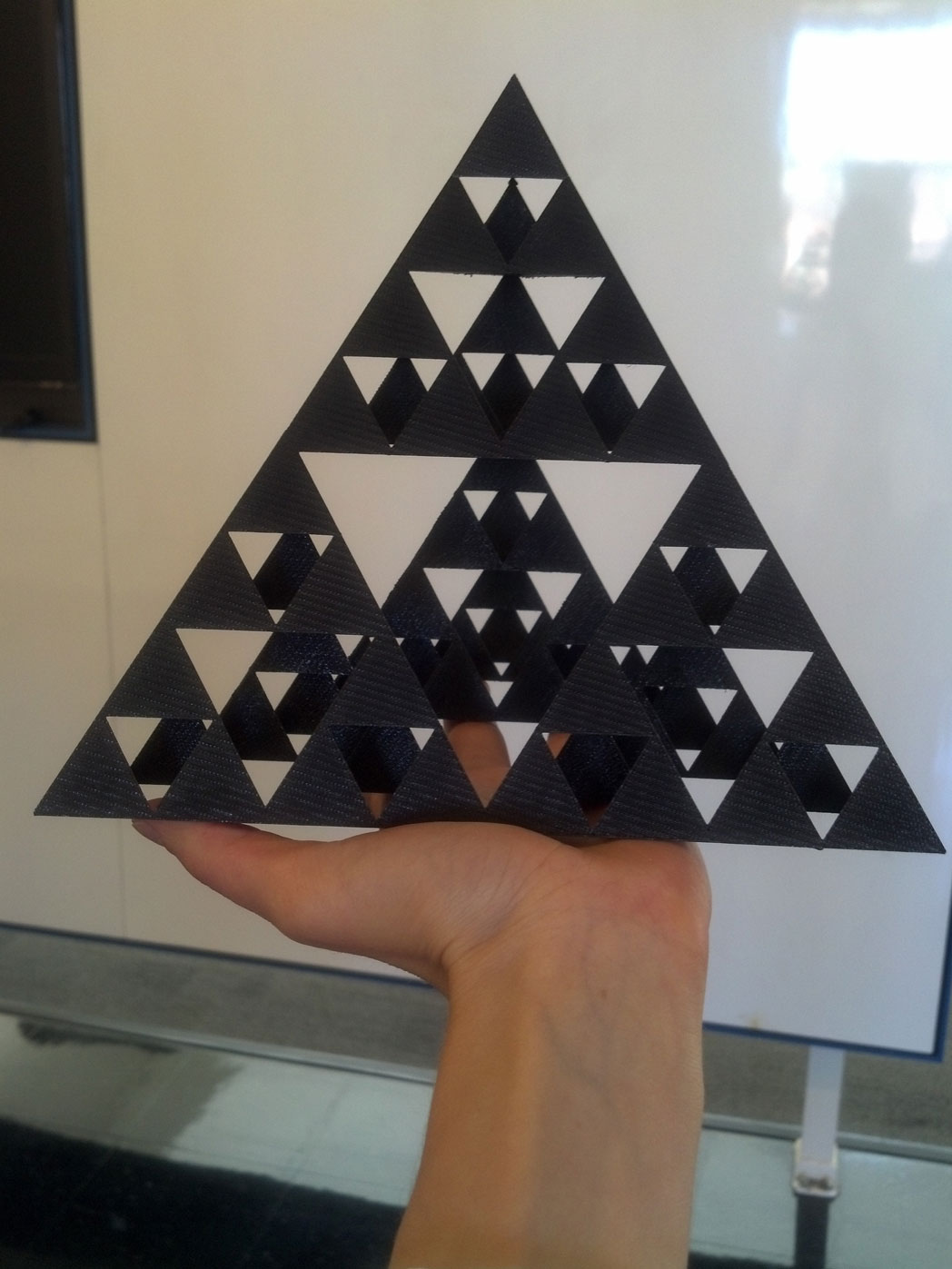

| Printed on the Makerbot | ||||||||||||

| Printing Problems | ||||||||||||

| The difficult thing with the Makerbot, even with the small structure made up of just 2 tetrahedra, was eliminating the support material. The crevices were too small and the connecting joints too delicate to effectively and cleanly get rid of the support material without breaking anything. Hence, for the bigger structure, I turned to the Dimension printer: The Makerbot was also rather unpredictable, and quit 96% into the job, leaving the pyramid tip-less. Didn't seem to be anything wrong with the file, so the pause was confusing. Someone said that there exists another software to check the file *specifically* for Makerbot, but I was too excited about the Dimension at that point to continue trouble-shooting Makerbot. | ||||||||||||

|

||||||||||||

|

||||||||||||

| Printed on the Dimension printer | ||||||||||||

| 3D Scanning | ||||||||||||

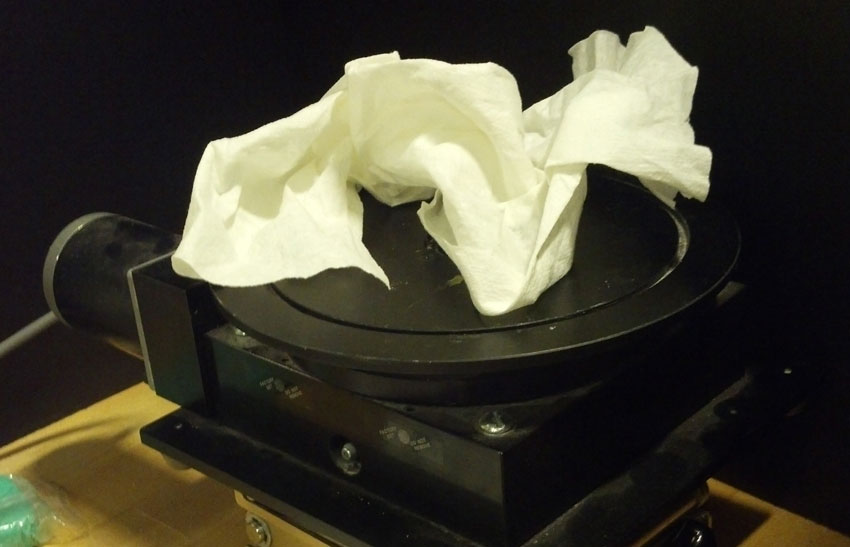

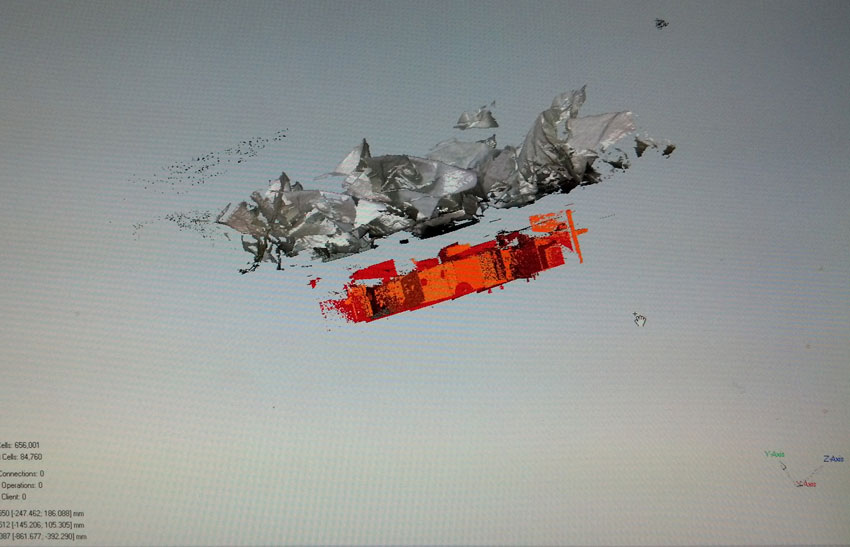

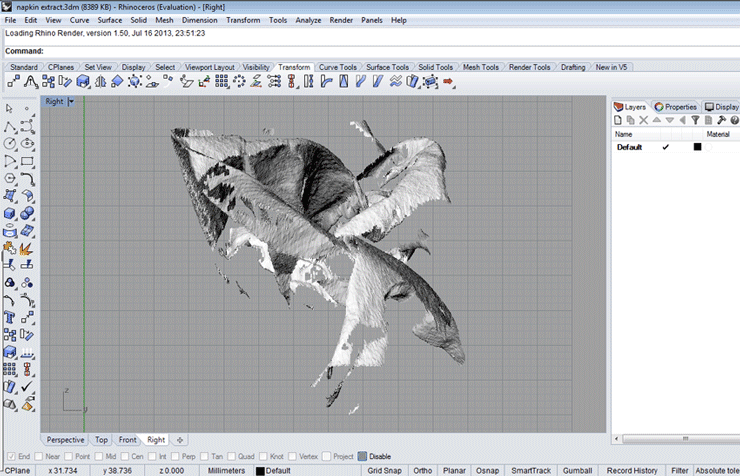

| I wanted to scan something that would be very irregular, and took a crumpled napkin. However great the intent, the scan was far from precise enough to account for all the details in the object. Despite that, playing with the surface was very fun afterward - felt like a mesh of a folded protein, where I was trying to find some continuous bits and find some magic in the surface. | ||||||||||||

|

||||||||||||

| The folded paper napkin as object to be scanned | ||||||||||||

|

||||||||||||

| Using Geometric Studio to remove unneeded portions of the scan | ||||||||||||

|

||||||||||||

| Playing with a portion of the napkin surface in Rhino | ||||||||||||

| Lessons | ||||||||||||

| One thing that I will absolutely get my hands on next time is Grasshopper used with Rhino. Now that I understand how Rhino software works in terms of meshes and surfaces, and what is actually needed to speak to a 3D printer, using parametric assistants would speed up the process significantly. For 3D printing, I would like to try using the 123DCatch that everyone was talking about and see how well it does with something rather complex like a crumpled piece of paper. Also I'd like to figure out ways of manipulating a surface like that in Rhino better: I was able to fill holes in the mesh, but each hole had to be pointed out manually. When I tried to explode the curves, Rhino froze, but another way of adding volume for the missing bits, or even letting new volumes intentionally alter the original shape - would be great to learn. | ||||||||||||

| Copyright 2013 by Anya Yermakova | ||||||||||||