This week for composites I really wanted to make something useful, related to my final project, and incorporated some features from previous weeks as well. I got close, but not all the way.

More specifically, the brief was to get familiar with the process of laying up a thin composite material. So, my first thought was to try and make some type of fenders for my bicycle since mine just broke.

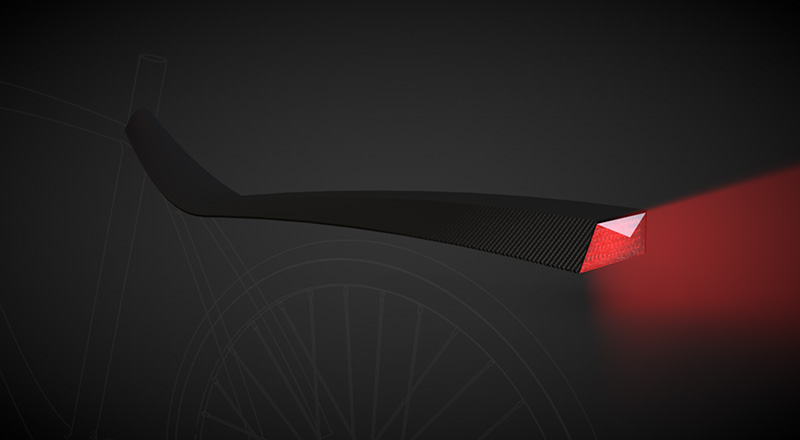

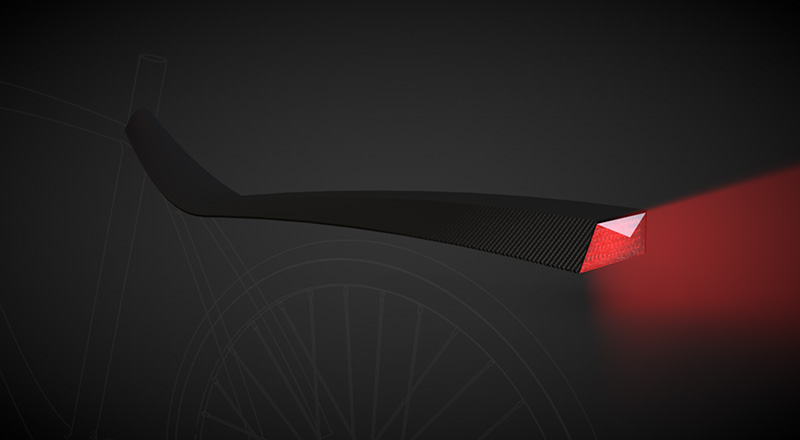

To up the ante and absolve some of my issues with the mold design and issues with fenders themselves, I also decided to make just a "mudguard". (bakc fender only, usually more flat, often connects to seatpost instead of the skewer) However, this one directly integrates a taillight for simplicity and better visibility.

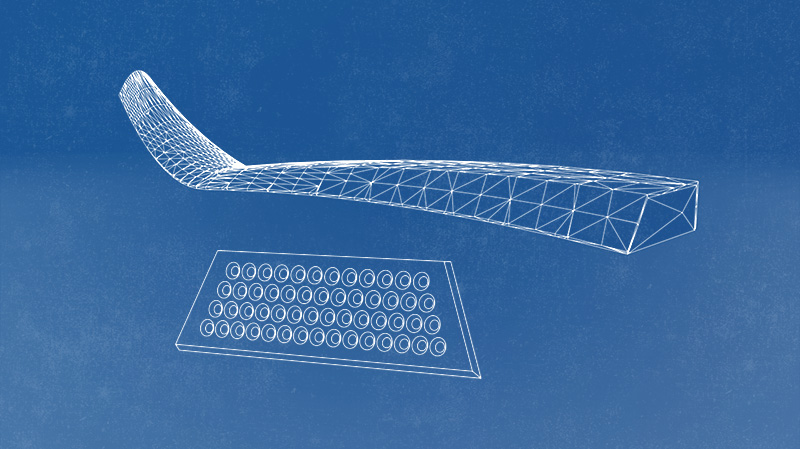

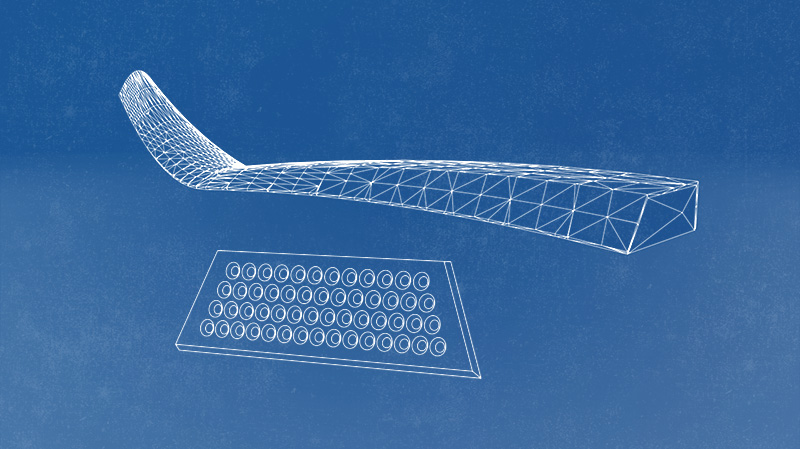

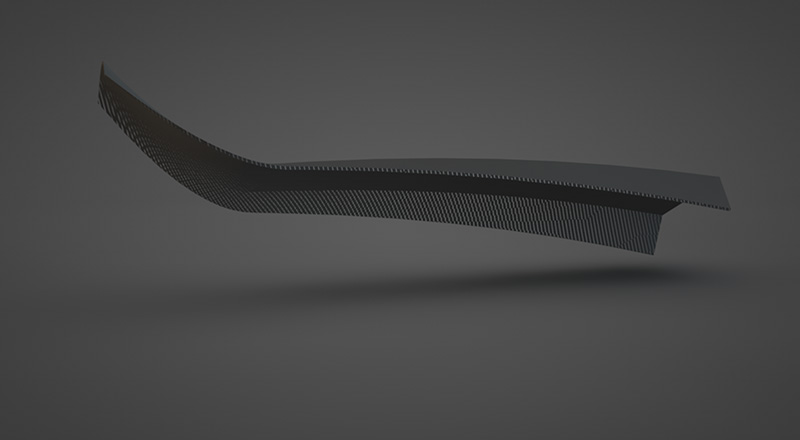

This splits up the project into two parts: composites and molding/casting because I wanted a custom lens for the taillight itself. For the composites section, I used Solidworks and the tutorial from Jared to design my mold.

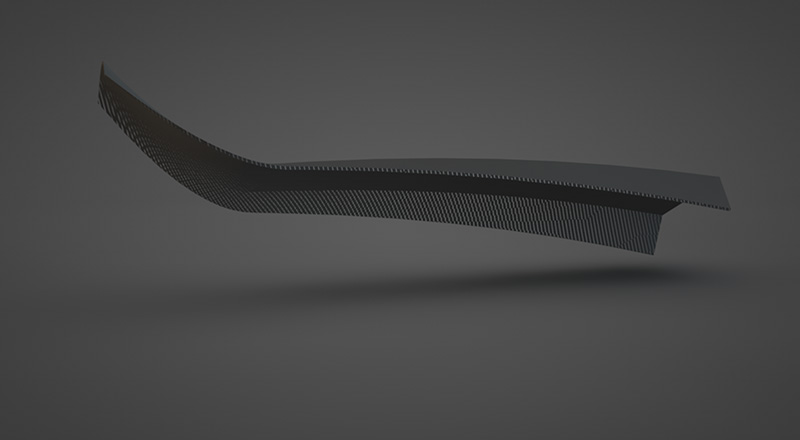

Because we're dealing with fabric and glue, we can't really create something with huge volume and instead treat it like a thick sheet of paper. Ideally this would be out of carbon fiber and/or painted black.

We've got a nice vacuum bag setup so I didn't have to worry about creating a two-sided mold. Instead, by pulling the vacuum, the fibers press against the one side and create exactly the hollow molded shape I needed.

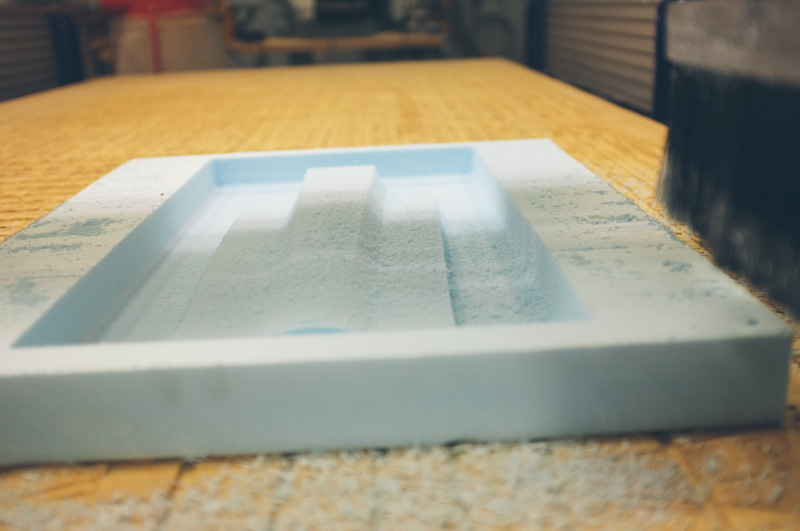

Added four layers of the burlap material on top of the saran-wrapped foam mold (to keep it from sticking), then put a layer of the perforated plastic breather material and two thick layers of the cotton.

Pulled the vacuum with Leigh and crossed my fingers. Anecdotally, the dot pattern from the epoxy leaking just a smidge is really neat.

It came out of the bag really cleanly!

I then trimmed off the extra with shears to get the final tail piece. It's rock solid and it turned out way better than I expected from burlap. Having the extra, horizontal planar width on the sides definitely helped cut this thing really cleanly.

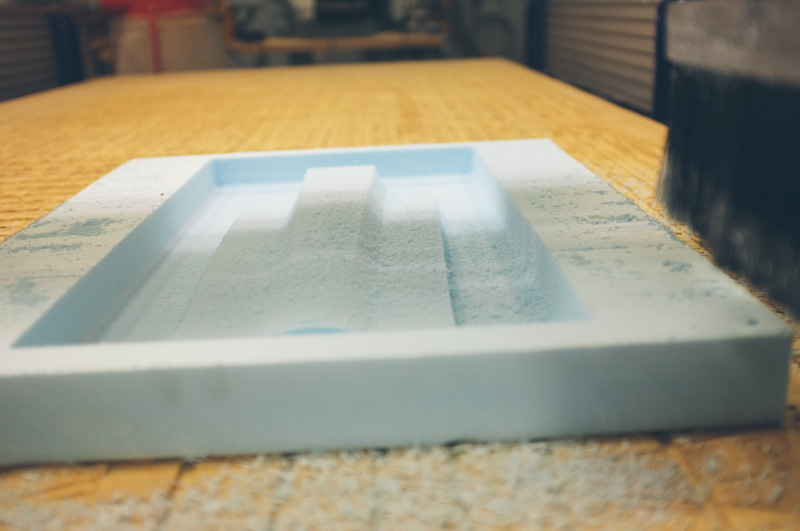

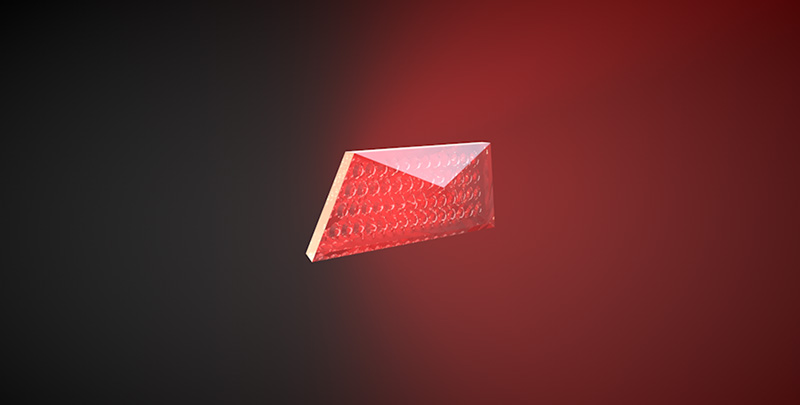

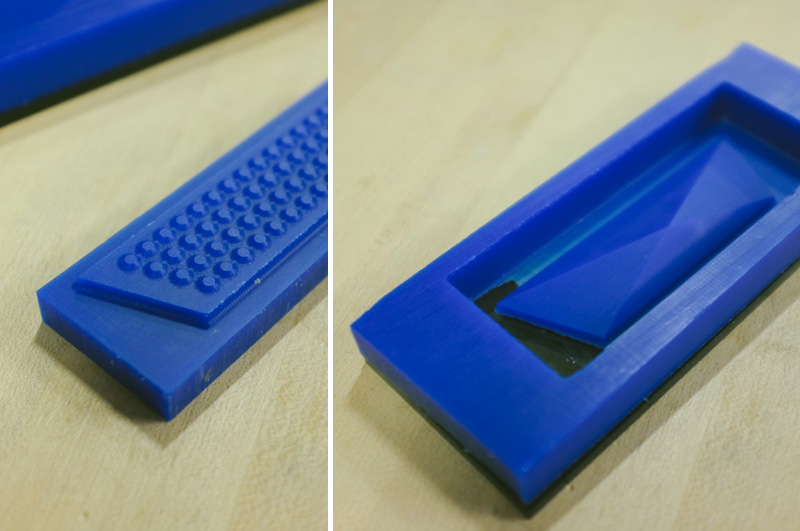

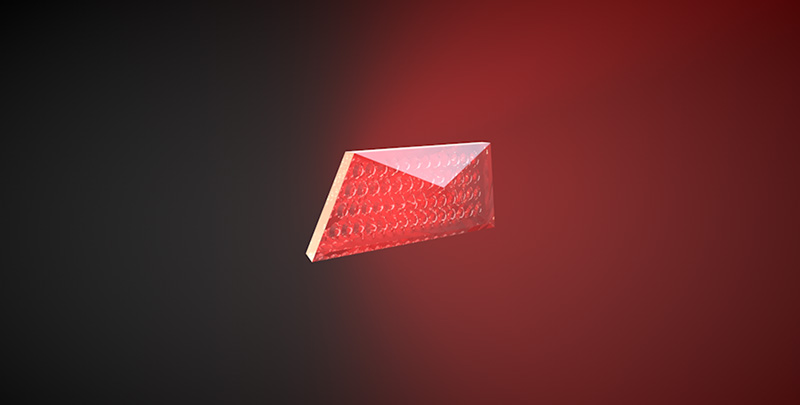

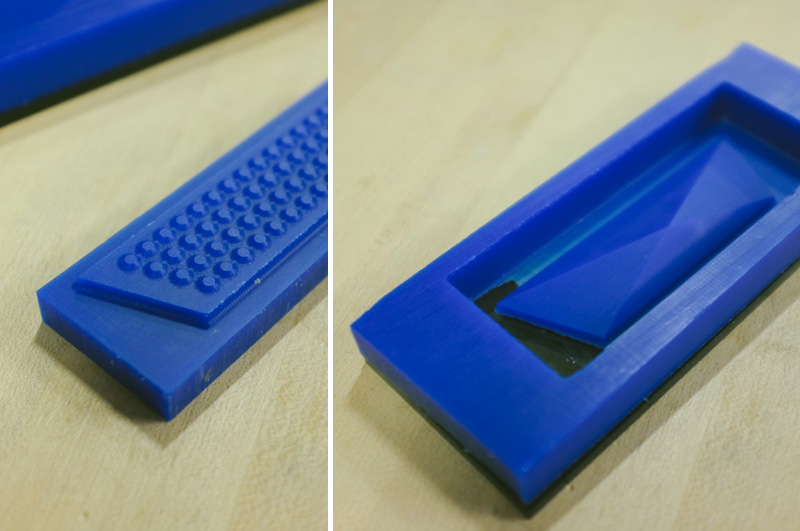

As for the lens of the taillight, I really wanted to do something custom. If I didn't, the design language wouldn't match the fender at all and it would kill any point of integrating the two.

I only managed to get as far as creating the wax and oomoo molds this week, but I've already bought and prepped the crystal clear resin to cast with the red dye. Hopefully it'll look the way I expect it to and the optical qualities will matchup. Until next time.