Project 0/13: Final Project Updated Thoughts - Cybiernetics

Beer drones is an idea I've had for a number of years now and it seems appropriate to develop the idea at this point. I realized that the gripper, while a great product, is too focused on mechanical design and as such is not as interesting of a project for this class. I would really like to spend the next couple of weeks really focusing on learning some networking and embedded systems skills rather than grinding on a mechanical design project. So...

Cybiernetics as a whole was inspired by differential games. I wanted a platform to develop an understanding of optimization and pursuit and evasion optimization techniques. An empty cup must evade the pursuing beerbot who is intent on refilling the empty cup. The complete system would include fluid level sensing, spatial triangulation, vehicle design and kinematics and of course communication and visualization. This project seems appropriate because it can be parsed into smaller, incremental projects that allow an agile development framework. I can pick off pieces to solve and each one is a stand-alone unit. As I see it the basice concepts are the following:

- Cup sensors

- Fluid level sensing

- Radio transmission

- Spatial triangulation

- Packaing

- Beer bot

- Mechanical design of vehicle

- Mechanical design of dispenser

- Kinematics of transportation

- Position Tracking

- Task queue

Project 0: Final Project Preliminary Thoughts - Powered Reacher

In our great years some tasks become more burdensome than we would have imagined. Joints stiffen and become difficult or painful to move. Certain conditions can make it very difficult to reach for items fallen to the ground or otherwise out of reach. My mother, an occupational therapist, has spent thirty years helping people get back to their daily lives and has become frustrated with the limited options available to help people reach for fallen items. As her son and a mechanical engineer and robotics designer, I have been tasked with spending a little time to innovate a lightweight, affordable gripping technology for disabled individuals. (note: I was asked to develop this probably two years ago, and I had gotten as far as ordering some vacuum pumps)

There has been little innovation in the tools available for patients living on their own over the years. The current state of the art is the ultra-cheap string actuated gripper. Despite commonly being prescribed, Judy Carney explains, most patients either cannot hold the narrow handles, or have the strength to tighten a grip. The average reacher is something of the following (the one on the right being one of the most "designed" products available):

The product design process generally involves:

- Identification of the core problems that must be solved.

- Evaluation of the current states of the art.

- Brainstorm additional possible solutions.

- Identify anchor design rules to follow

- Industrial design / prototyping

- Hardware design / prototyping / sourcing components

- Revisit industrial design

- Detail hardware design

- Design verification prototypes

- Manufacture

While not overly complex, this project seems sufficiently scoped to be reasonable to accomplish while also leveraging a number of the skills we will develop in How to Make Almost Anything: electronics, sensors, actuators, carbon fiber, computer controlled cutting (cnc machining), 3d scanning and printing. There are two actuator technologies I am considering for this project. One is the jamming gripper and the other would be using twisted-strings with underactuated fingers. There are pros and cons to each one that will be mentioned below.

Jamming Gripper

The jamming gripper was designed by students at Cornell University (I think in collaboration with iRobot as well?) and seems like the simplest mechanism to allow someone to pick up almost anything from the ground. It is basically a balloon filled with a course substance, e.g. dry coffee grounds, when a vacuum pulls all of the air from the balloon the ambient airpressure compresses all of the bits of coffee into eachother and their high surface area features lock into position. This makes a device that can easily conform to any shape, can hold this shape, and then release when commanded. The only downside to this actuator is the difficulty in picking up a flat piece of paper as grasping is not actually possible.

Underactuated Fingers with Tisted String Gearing

The underactuated finger would allow grasping and conforming to arbitrary shapes, at a cost of increased complexity. The twisted string is a gearing system that has gathered a bit of interest in the robotics community over the last number of years due to its light weight, low cost and large gearing capbilities. This actuator combination is very cutting edge in robotics, but of course includes some complexity in design and control.

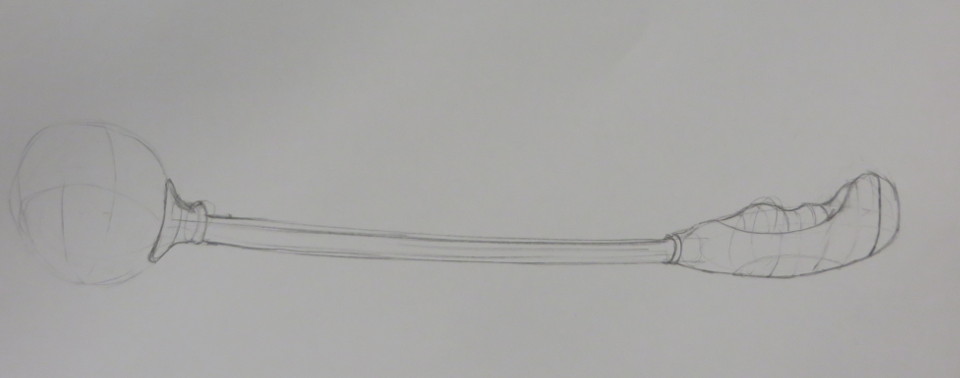

Rough (very) Sketch of Jamming Reacher

A very rough representation of a jamming gripper fashioned into a reacher is shown below. Vacuum pump, battery, electronics would be packaged in the handle. Additionally, a portion of the handle would be pressure sensitive in order to actuate the gripper without requiring significant force application by the user.