Composites

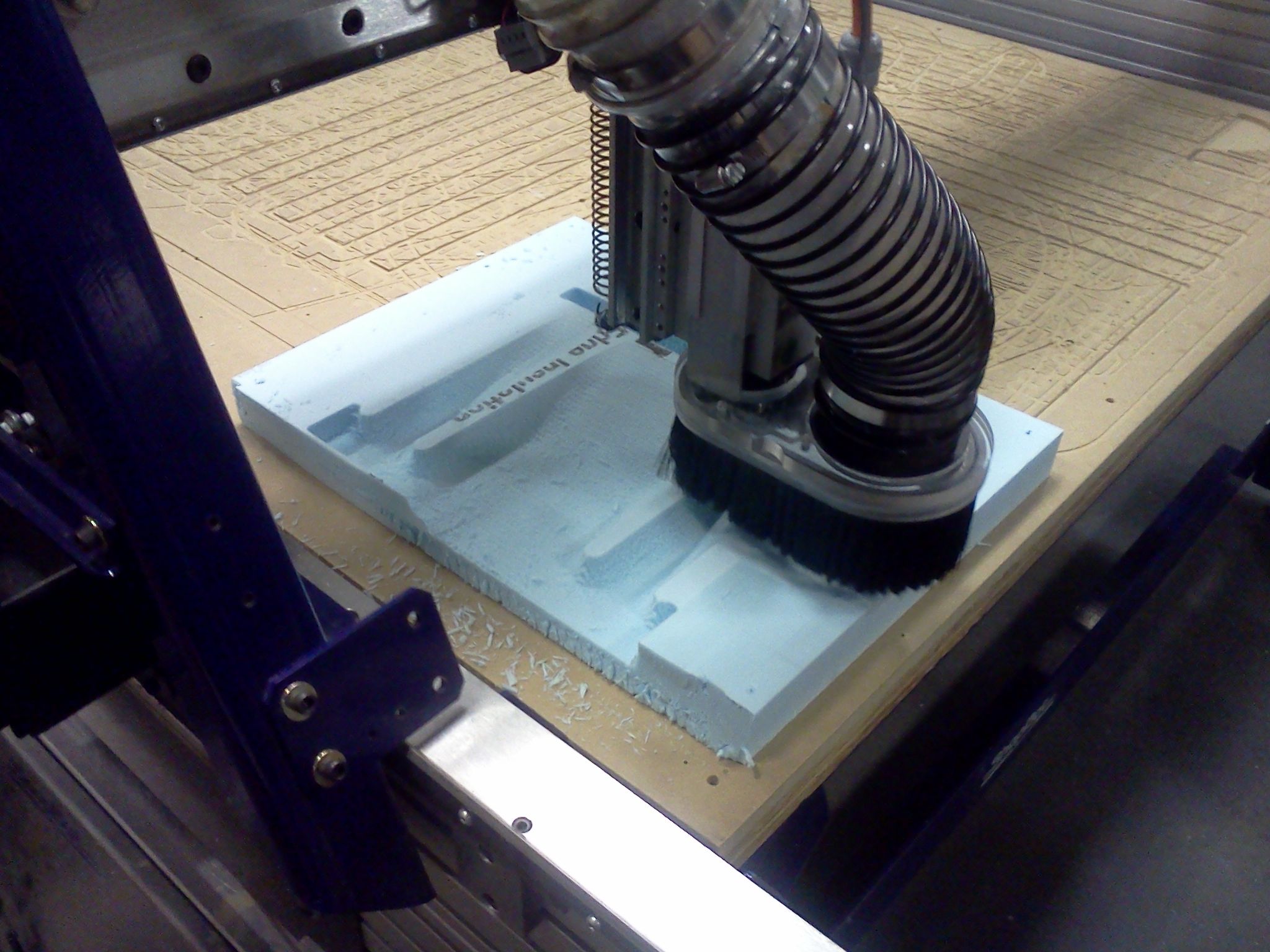

This week we made composites. I designed a tray for a dish drainer in SolidWorks (These are never slanted enough to actually drain into the sink).

The final product is porous, so it might not actually make a good dish drainer. Is there something good to coat it with to make it waterproof?

- One option is just using more epoxy.

- Alternatively you could try using a coat of finishing epoxy. Something like West System 207 can be painted on -- then the brush strokes can be removed with a heat gun.

Composites are made up of a matrix and a fiber. Epoxy is often used for the matrix -- but not always: Che-Wei and Taylor made composites with burlap and drystone.

To fit the burlap to the mold I just pressed a large sheet in, and drew an outline around the edge with a sharpie. This was a little clumsy, but it got the job done.

Slits around the tight corners help the burlap fold into place.

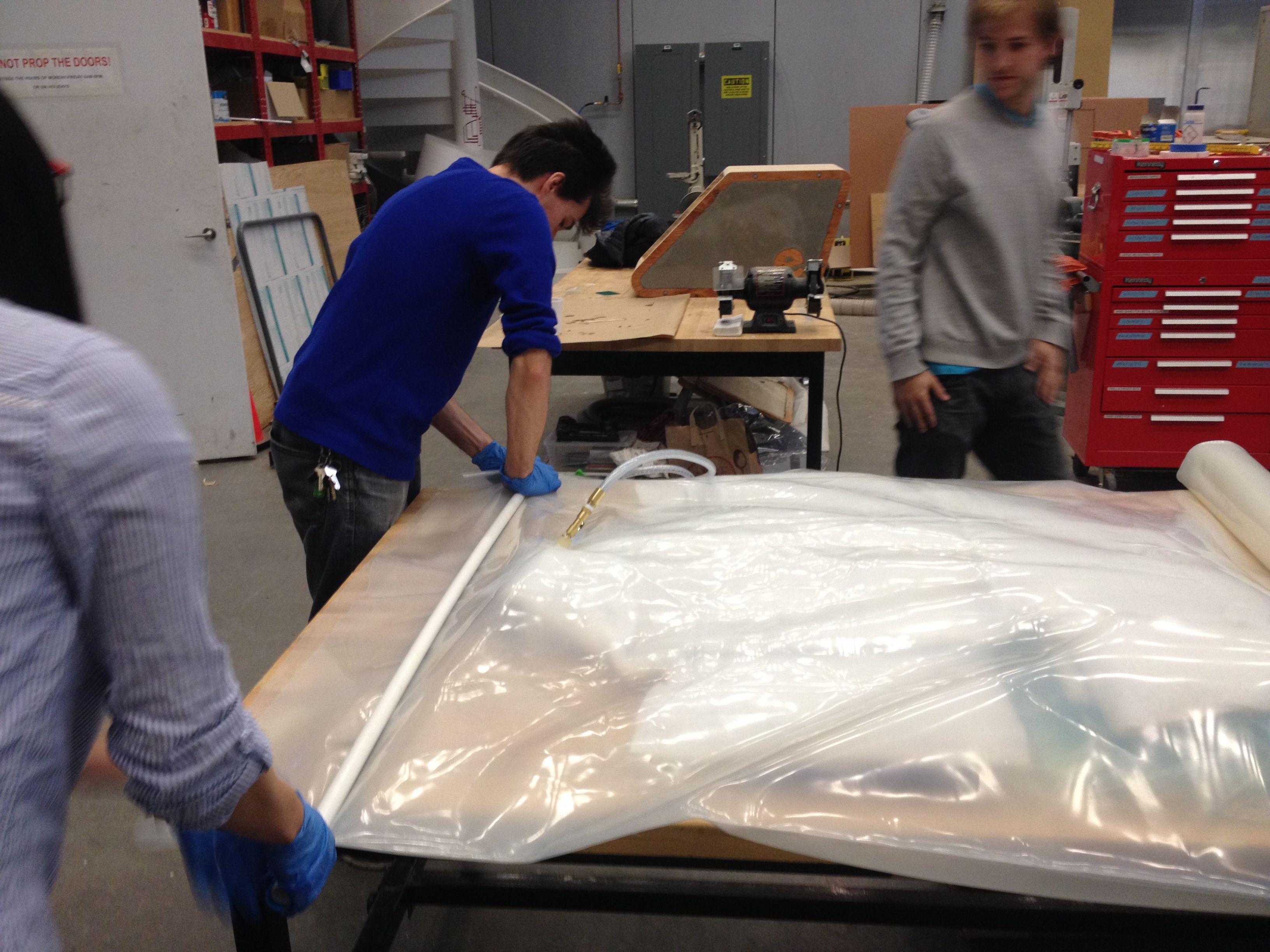

Sealing projects in the vacuum bag

After the resin dried

I didn't use enough perforated plastic to fully surround my composite. Some of the foam snorkel got caught in the actual glue.

Is this material safe to cut in the band saw? If so, trimming the edges should be quite easy.

(Yes, While many composites cannot be safely cut with a band saw, these are all natural, and can be cut safely.