Milling with the Modela

This 6-3 major realizes she knows jack shit about chipsMy initial attempts at boardmaking:

Nooooooooooooo

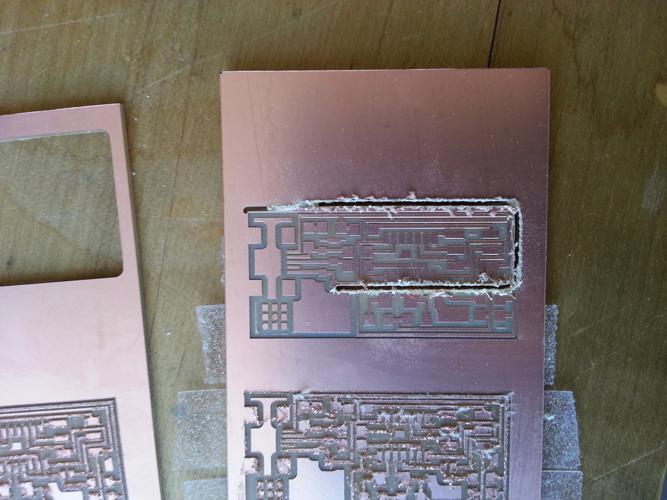

The first board on the left: initially, the bit refused to cut deeply into the board, and after a few passes was practically hovering over the board. Lesson learned: you actually have to tighten the screws on the modela head quite a bit to make sure the bit doesn't move.

The bottom cut on the right board: so that's what a dull bit looks like...

The top cut on the right board: oh good, switching to a new sharp 1/64 tip did the trick! Now let's try milling the board out with this 1/32 tip - what? Noooooo!

(Turns out if you don't tighten the 1/32 tip enough either, the bit might decide to get loose and drill itself into the board. And the sacrificial layer below.)

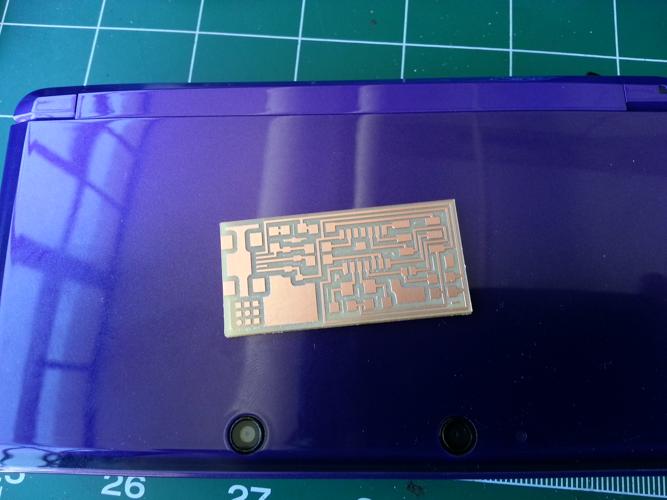

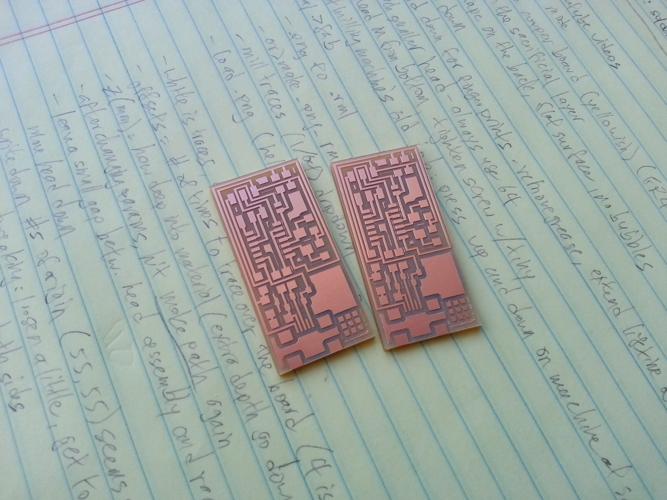

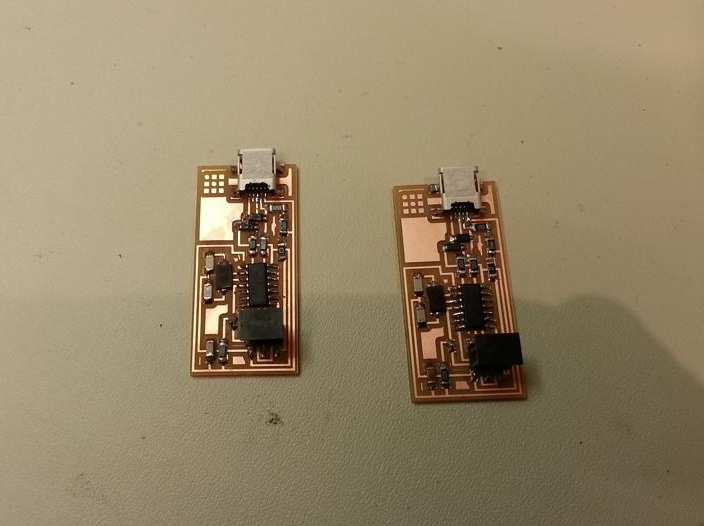

But I finally came out with a correctly-milled board. And then I made a second one because the risk of something *else* going wrong was pretty high.

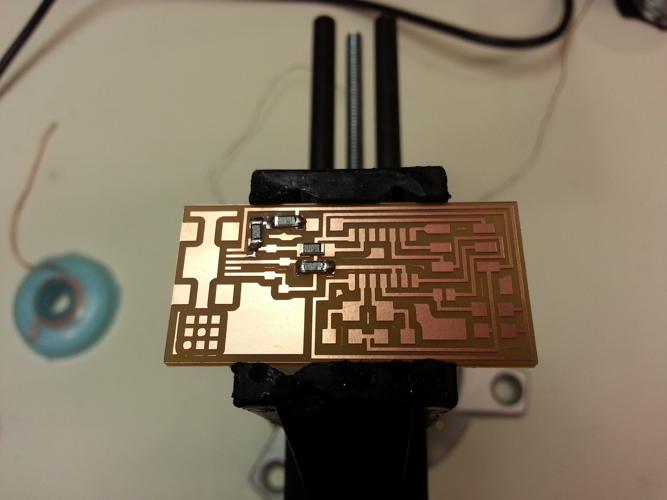

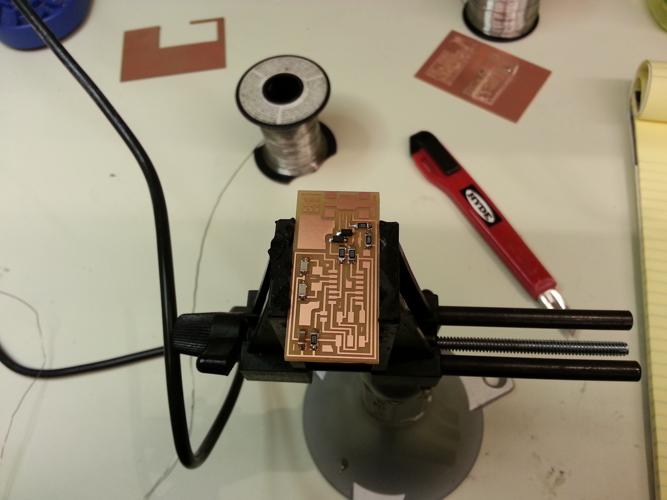

I then proceeded to solder both boards, and realized that you really need three hands for soldering: one to hold the component, one to hold the iron, and one to hold the solder wire. Pictures of the process and the two resulting boards below.

Unfortunately I ran into debug issues when I tried to program both boards with the AVR on the lab computer, and without expert eyes to check I can't be sure what the problem is. I might end up going back into lab to make a new board later, and programming that one.