Composites

You do not want resin shards anywhere near your mucuous membranesI decided that this week I'd try doing some armor design - specifically, a forearm guard in the unlikely situation that I'd need to block a sword. Or a knife. Priorities.

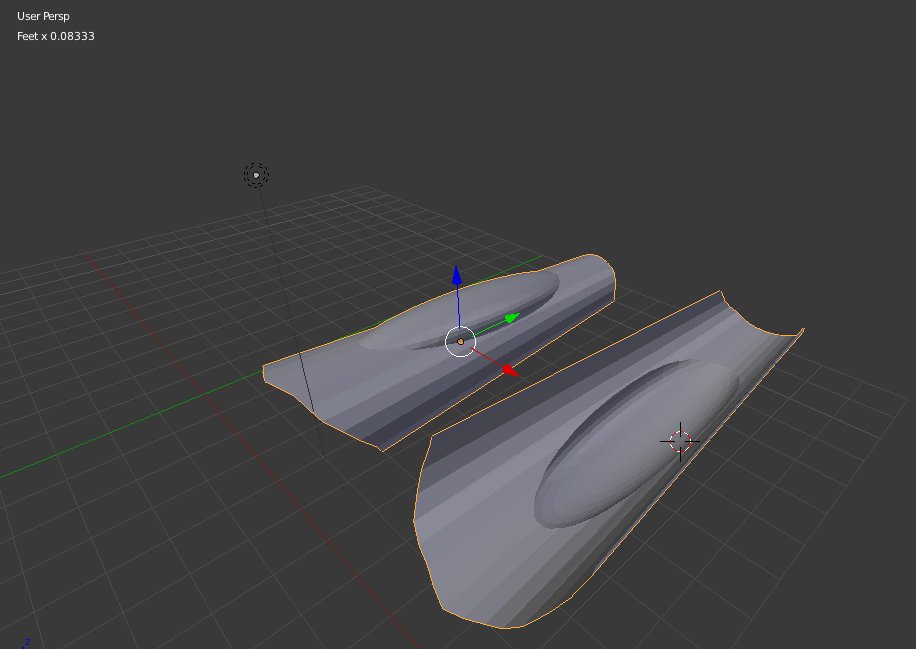

This was a project that was probably better suited to CAD design, since I knew the specific dimensions of my forearm at the wrist and at the elbow, but FreeCAD was inscrutable to me and I'd been using Blender for long enough that I'd grown (somewhat) fond of it. So I eventually modified my Blender workspace enough to work specifically in inches, created a cylinder with the necessary dimensions and length, and reshaped it appropriately to fit an arm. I also added a round-ish surface object to give the armguard some details; as it turned out, this would be vital in helping me fit the two halves of the model together.

I milled out the mold on the shopbot; below is a picture showing the milling in progress. The farther shape has been smoothed out via the finishing path already, and you can see the difference between the rough cut on the closer shape and the smoothness of the farther shape. I also realized too late that the edges of the concave mold (the farther object) were too thin for the foam to hold itself together at the very edges; the picture shows jagged edges on the sides of the concave mold, where the foam was stripped away unevenly by the drill tip.

The below pictures of the finished mold show the jagged edges of the concave part more clearly. The two parts did, however, fit together well.

During the assembly phase of molding, however, I ran into some problems putting together the plastic + fluffy absorber + hole-filled plastic + actual resin-filled burlap:

- I had some sort of strange compulsion to not waste material, so I ended up scrounging someone else's scraps of burlap and fluffy absorber which were roughly the same shape as my mold. However, this meant I didn't have a carefully-calculated fit from material to mold, so some parts stuck out/weren't covered enough. If you're reading this, DON'T BE SCROOGEY WITH MATERIALS. At least for everything that's not the resin/epoxy.

- When I clamped my two pieces of the mold together on top of the burlap, I realized that a cylindrical mold with no flat sides which could "anchor" together was a poor choice. The two pieces began slipping sideways (think a cover rotating about a cylinder) when I applied pressure through the clamps, and if not for the round decorative bulge on the surface of the armguard, the slipping would have been much worse.

- My saran wrap fully covered my foam molds, but the hole-filled plastic did not completely block off the fluffy absorber from the burlap, so some parts of the absorber, filled with resin, contacted the burlap and cured that way. What this resulted in was chunks of fluffy white thing stuck to an otherwise perfectly-respectable piece of forearm armor.

The other thing that I had to watch out for was resin shards: when I tried to remove the cured burlap from the mold and saran wrap, a lot of resin which had leaked out and cured was shattered in the process, leaving a ton of tiny sharp fragments all over the table, the edges of the piece, and my clothes. I couldn't exactly wear something with jagged edges as an arm guard, so it took me about half an hours with scissors to clip away some of the most egregious sharp bits before I dared let it near my arm. Thankfully, the piece actually *fit*, but I hadn't included arm straps in the design (intending to glue them on later).

Some examples of how messy the finished workspace was. Definitely vaccuum up your resin shards! No one else wants to.