My first time in the lab

Week 1: Press-fit construction

I wanted to create a 2D, press-fit set with only one type of piece that could be used to create many different shapes (inspiration: Legos).

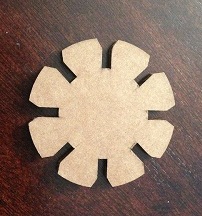

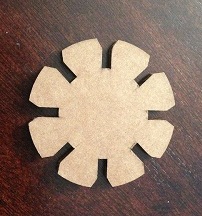

I used this piece, which I designed in Inkscape, to test the width and shape of the joints/notches. I ended up using 0.16" which provided a tight fit with the 0.167" width of the cardboard.

These pieces with 8 notches at 45 degree angles enabled me to create this cool sphere-like object:

Now that I had the joint basics down, I wanted to build a 2D kit that could build a 3D object that moved mechanically. I thought a cool concept would be a physical "dimmer switch" for a candle (or in this case a light bulb so I don't burn the cardboard).

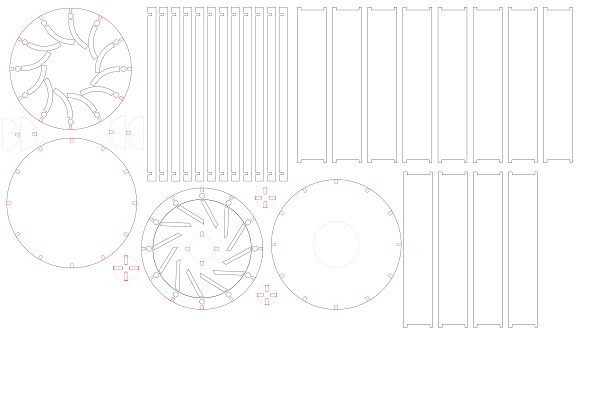

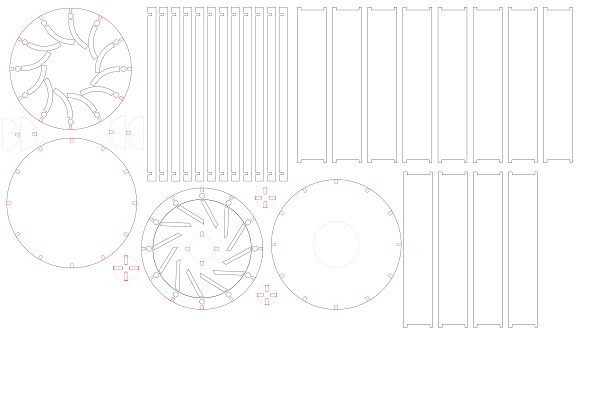

I decided a lantern with vertical blinds around it would do the trick. After drawing an initial concept of what it could look like on paper, I used Inkscape to design the actual parts.

I learned the hard way that 3D, parametric CAD software would probably have been the easier way to go. I made each measurement by hand, marking them on physical paper. After two attempts at full construction, I had all the parts cut.

As a side note regarding laser cutting: I used the following settings: 65/33/~800 Hz. The piece of cardboard I used was slightly warped which made the cuts toward the bottom right not to fully cut through. After trying to finish the cuts manually with a knife, I scrapped it and just re-cut the parts that were affected.

Once the pieces were all properly cut, I had to assemble the lantern. This was more difficult than I expected as each individual blind had to be fit into its hole and cut out path, essentially simultaneously (see below):

In the end though, I was able to get it all assembled and it worked reasonably well. By twisting the top it "opened" and "closed" the blinds. The left image is with the lantern open or "bright" and the right image is it closed or "dim". (I ordered a bulb on Amazon to add to it; stay tuned)

Fortunately the parts all fit tightly (my calculations worked!), but because the cardboard has significant flex to it, the twisting shortened the entire structure, making the blinds "stick" in their grooves because of the extra friction (see image and video below).

You can see it is somewhat difficult to twist open and closed. I believe the design will work even better with a harder, less-flexible material, but for now, I am happy with the final result.

One key takeaway I had was that while a 2D design software like Inkscape may work for something as simple as the first piece I made, with a more complicated, connected, moving-part project, a 3D, parametric CAD software would be much better.

Back