Toks Fifo

Student. Builder.

FabISP: In-Circuit Programmer

Overview

I built an ISP (In-System Programmer) using a Modela milling machine. The FabISP is capable of programming other chips that I'll be making in the future.

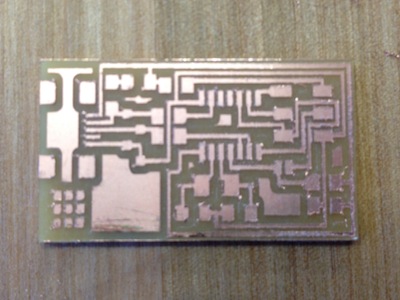

Milling Traces

I downloaded the default FabISP design image and loaded it unto the fab module. After taping the copper-plated board to the machine bed, I used the 1/64" bit to cut the traces. The most difficult part here wasn't in making sure the board was flat or changing the bit, it was figuring out how to use the Modela milling machine.

Milling Traces (Cont'd)

After milling the traces, I used a 1/32" bit to cut out the board. Here is the result. I followed this up by using a steel ruler to deburr the traces, and then I washed the board (with just water).

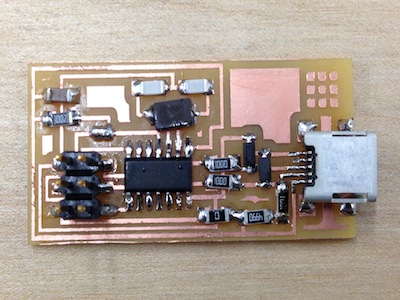

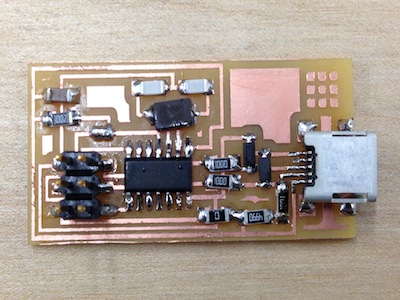

Soldering Components

Finding all the compoonents was a struggle, but soldering wasn't that bad (although the components were really small). The most difficult part here was in soldering the USB connector. I ended up putting a big blob of solder on all 5 traces, before wicking most of the solder out. With just the right amount of wicking time, I was left with those 5 beautiful connections.

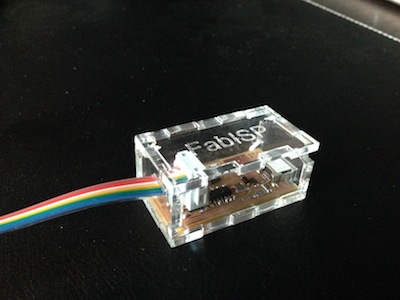

End

With a little help (and some very limited instructions online), uploading the firmware to the board went smoothly. I finished by creating a connecting wire for the board. I also created an acrylic press-fit case for the board using a design from Dan Sawada.

The whole process was a bit tedious. I was frightened that one bad soldering joint would screw up the whole board. I'm much more excited to use the board to make other things in the future!