Casting Metal Babbitt tutorial

Making the Mold

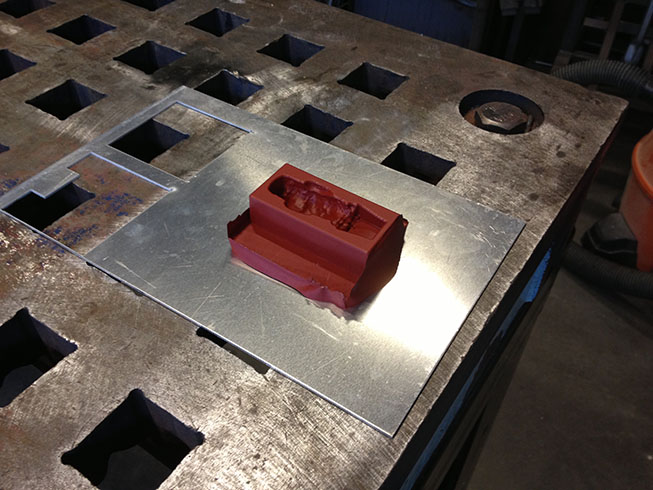

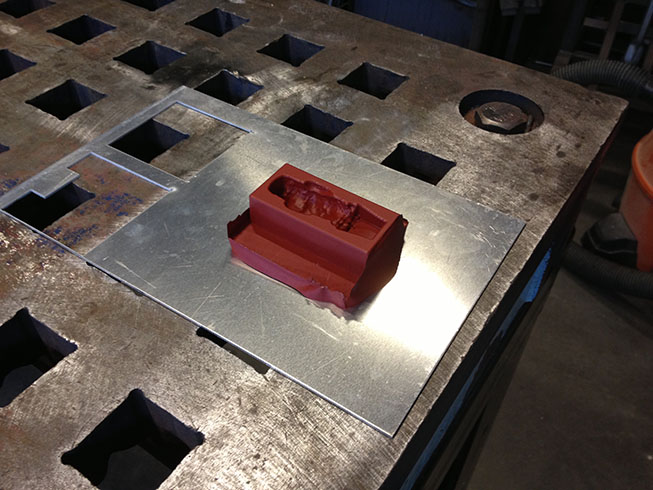

MoldMax 60 is suitable for higher temperatures than Oommoo. However it takes longer to set, and is more toxic. MSDS. Technical Bulliten.

- Silicon rubber compound (red, 100 parts mass)

- Tin based curing agent (blue, 3 parts mass)

- Mix together at 100 parts red to three parts blue

- Do the mixing under the ventilation hood

- Mix the silicon compound and curing agent into a third cup.

- Mix Mix Mix - until completely blended together >= 5 minutes?

- pot life - 40 min - after mixing, you have 40 minutes to pour the mold

- de-mold - 24 hours - after pouring the mold you must wait 24 hours before the mold has finished setting

Pouring the Metal Babbitt

- You need a partner to pour metal

- General casting advice: Think about the pants and shoes that you are wearing

- Place the mold on a piece of scrap metal on the metal table under the adjustable ventilation hood

- Place in the babbitt in the crucible, and melt it in the furnace

- 700 Fahrenheit

- 30-60 minutes in the furnace

Practice the choreography before actually pouring. This is a complex action -- make sure you understand what needs to happen before you actually take the crucible out of the furnace

- Open the furnace and take the crucible out with the tongs

- Carefully move the crucible to the table adjacent to the mold

- Here your partner wearing gloves will spoon the [JUNK] off the top of the melted babbitt and set it in the metal place next to your mold

- Pour the melted babbitt