Week 2

3D PRINTING

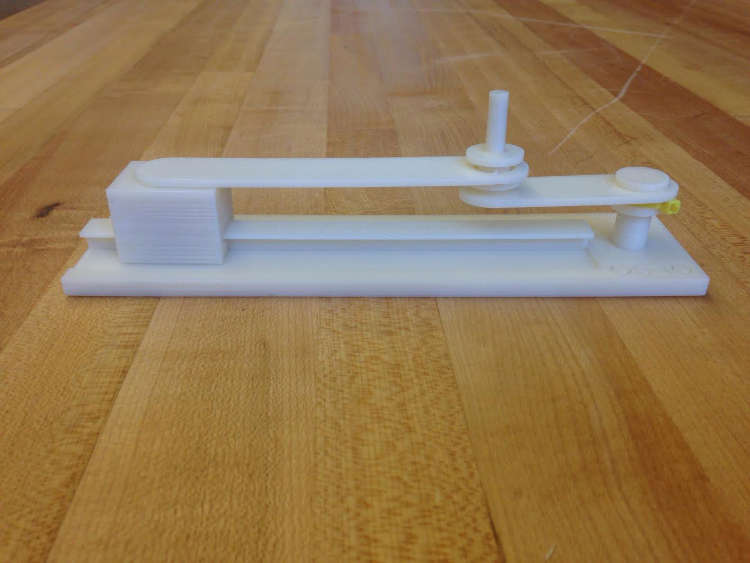

MY FIRST 3D PRINTED SLIDE-CRANK

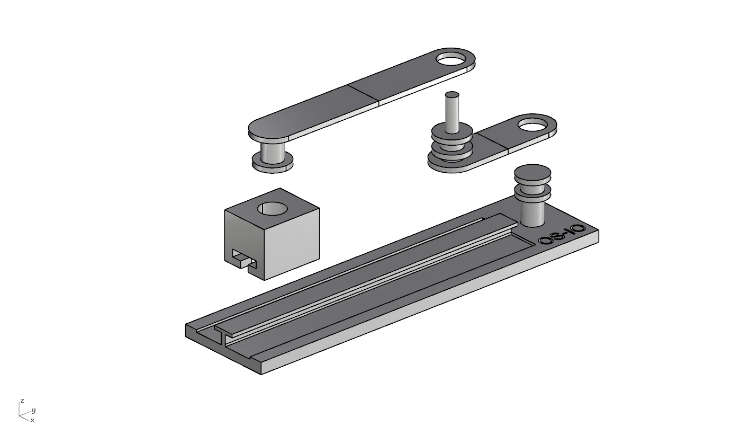

Assembly of componenets nested for the print. This print was an exercise in creating an operating mechanism made as one piece. There is no snap fit.

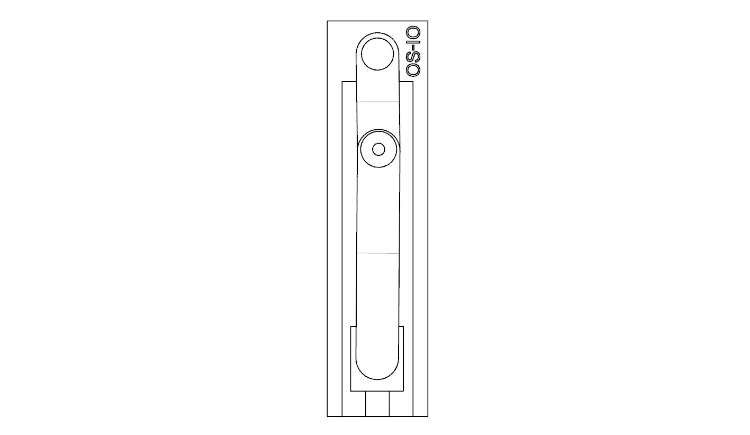

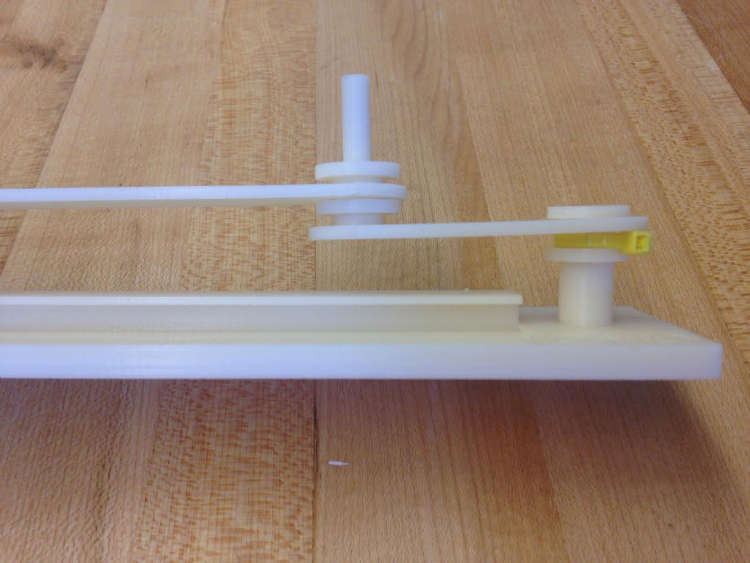

POSITIONING THE PIECE TO MINIMIZE USE OF SUPPORT MATERIAL

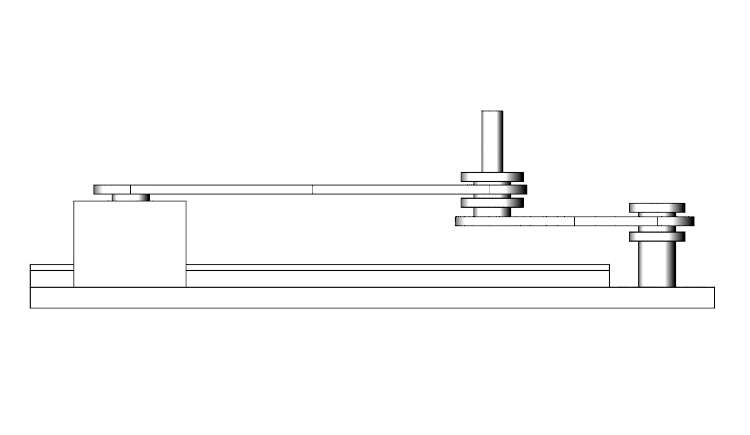

ELEVATION OF THE NESTED ELEMENTS

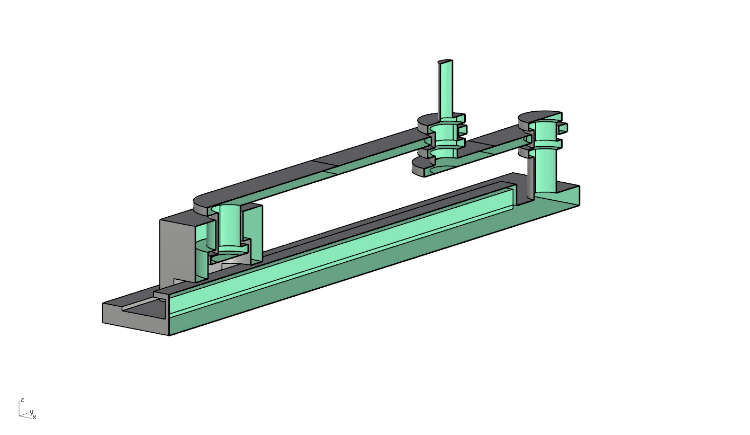

ASSEMBLY

WORKING PRINT!/p>

GIVEN THAT THE CRANK WAS PRINTED AS ALL ONE PIECE, I HAD TO BE LIBERAL WITH THE TOLERANCES, SO THAT THE PLASTIC DIDNT ACCIDENTALLY BIND. CONSEQUENTLY I HAD TO USE A ZIP-TIE IN A STRATEGIC LOCATION TO TIGHTEN THE ASSEMBLY

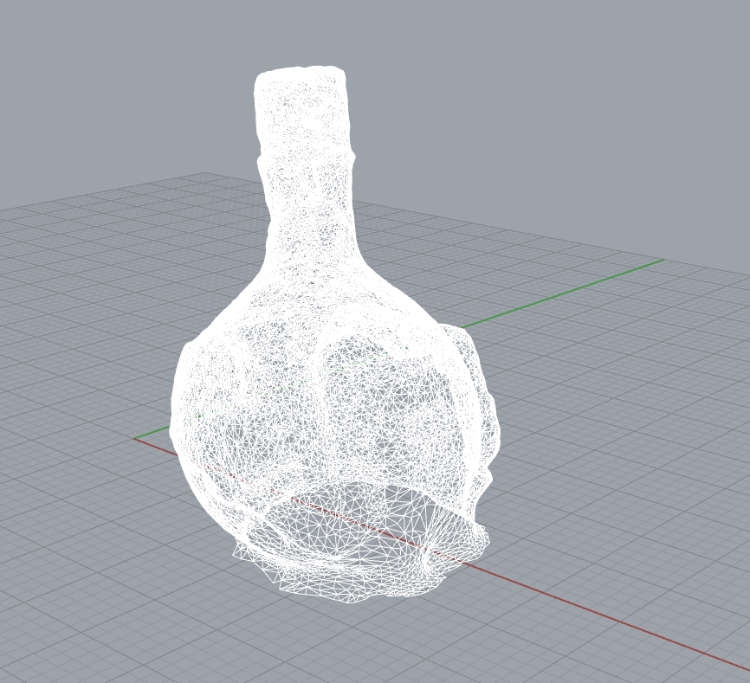

WOW! A 3D SCAN OF AN ARTISINAL BOTTLE ----- WORLDS COLLIDE!

NOT MY CLEANEST MESH - I DECIDED I WANTED TO CHALLENGE THE CAPABILITIES OF 123D CATCH. PRETTY UNDERWHELMING. IF I HAD ADDED A BLOCK OR SOME OTHER REGISTRATION POINT ON THE TABLE THEN I THINK MY OVERALL MESH QUALITY WOULD HAVE BEEN MUCH HIGHER. GIVEN THAT IT HAS MULTIPLE DEPTHS, IT SEEMS CLEAR THE ALGORITHM LOST ITS REFERENCE POINT.