I chose the Valentin board design because I found the snap-off functionality clever. I have never fabricated a PCB before, so this would be a learning experience.

Step 1: CAD/CAM

Milling the board on the Modela was super straight forward. Using the fab module, I only had to set the Z axis myself- everything else was a click or two away from pressing go.

(Note: someone left their tape to the left! I know, I should have cleaned it up. Next time!)

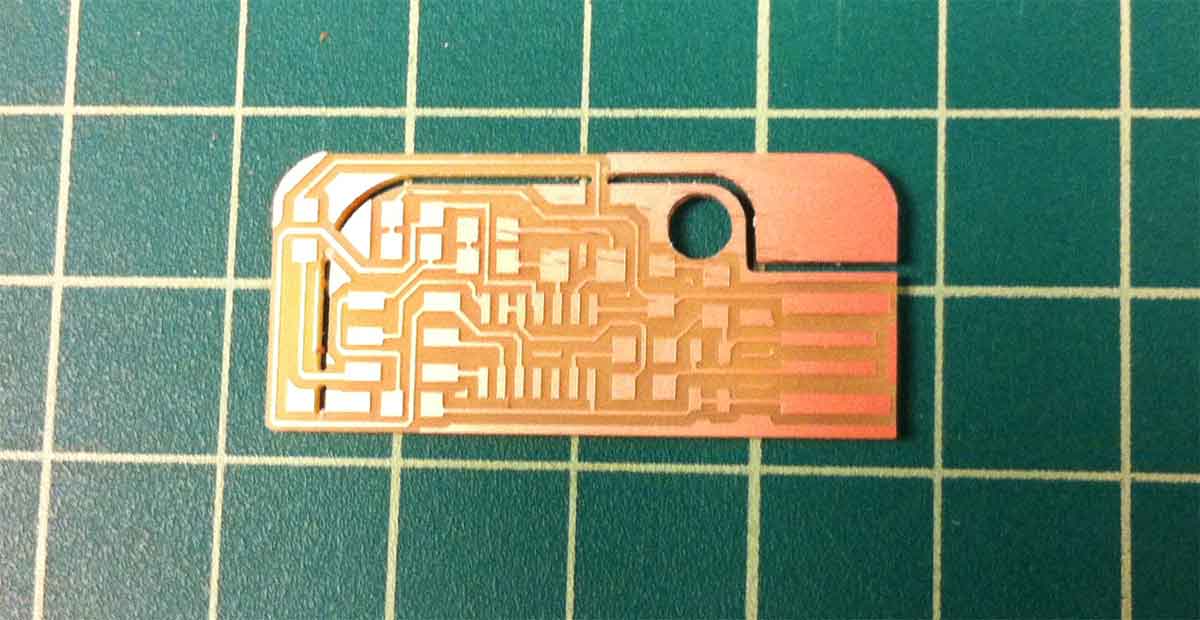

Step 2: Clean/Prep for Stuffing

Cleaning was easy as well, simply scraping away the milled copper with a straight edge ruler, and then washing the board with water.

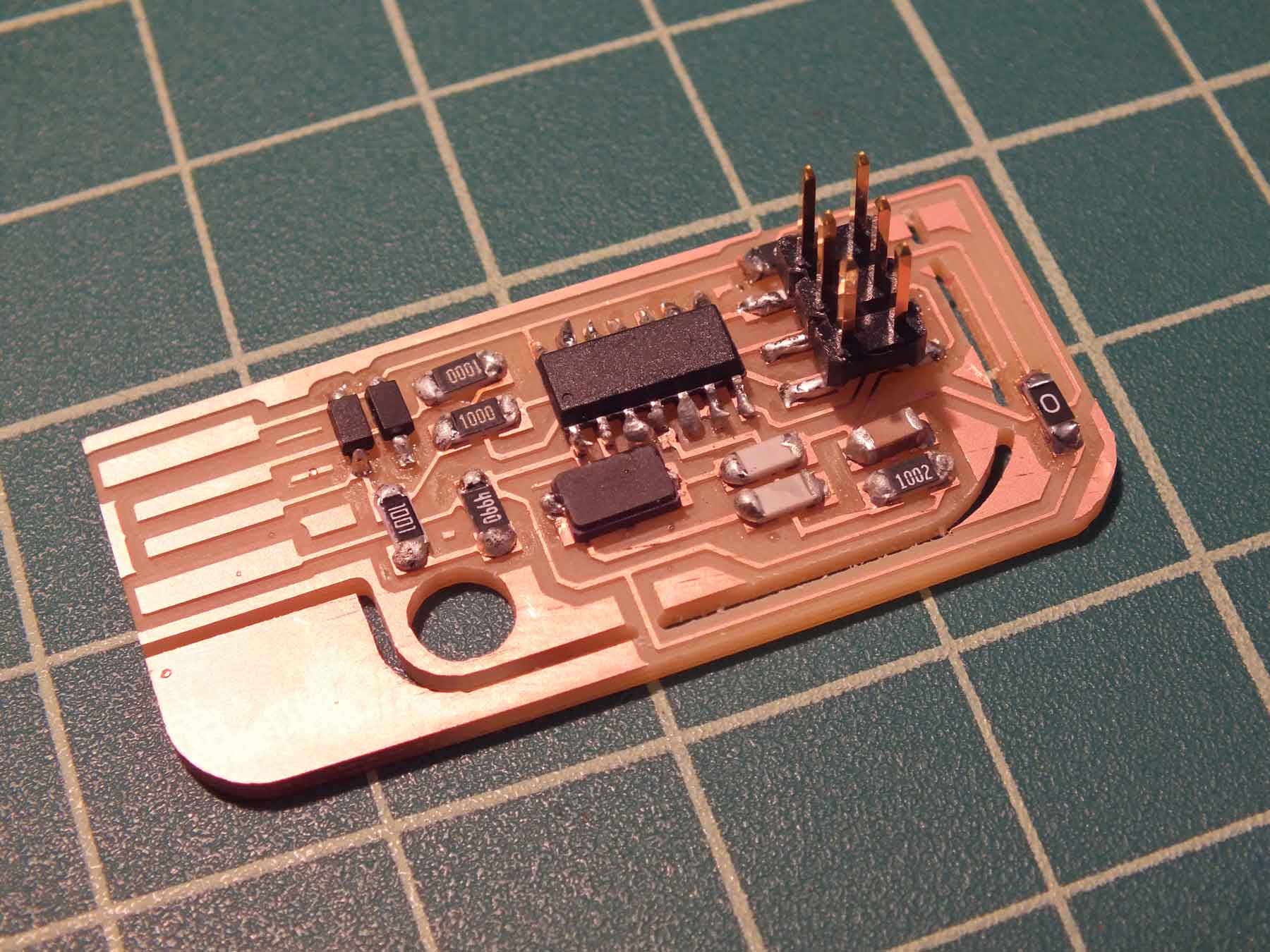

Step 3: Stuff+Solder

Stuffing was fairly easy. Soldering, on the other hand, will need some practice to get more consistent as well as faster. The whole board took me around an hour- should be more like 10-15 min.

I would like my solder connections to be cleaner and smaller, but for now I think they should work.

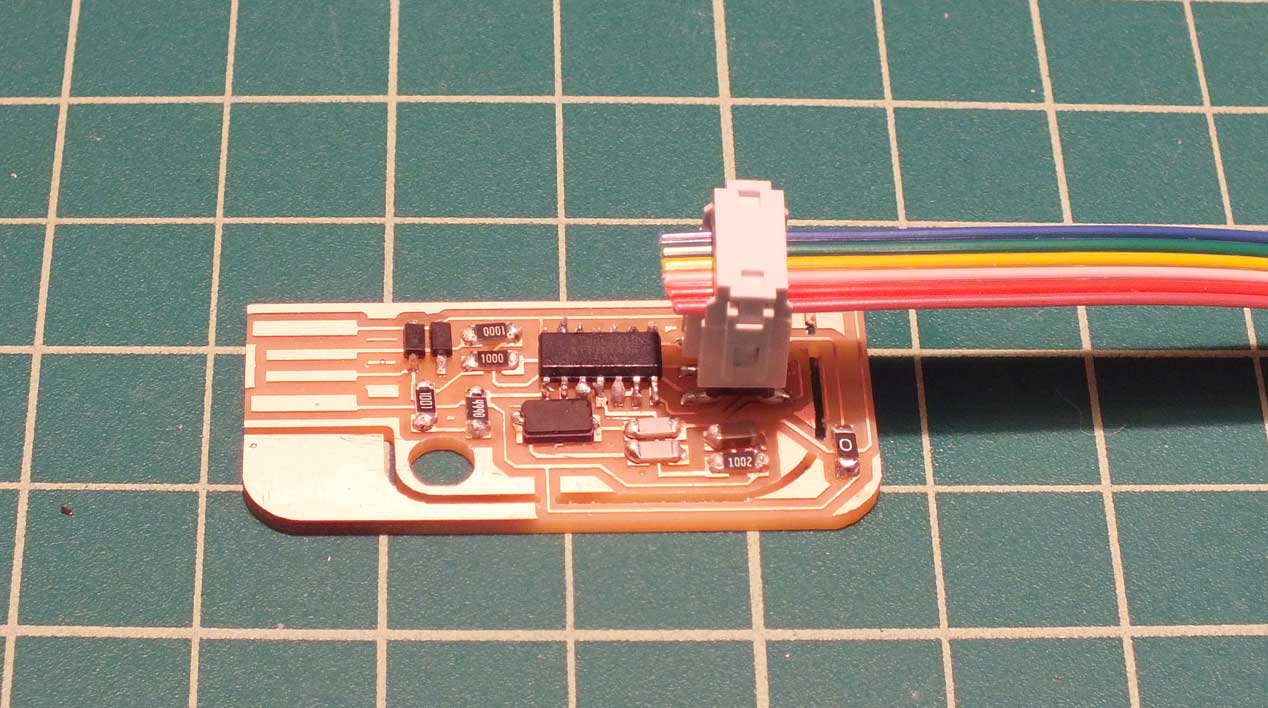

Step 4: Test/debug

To be completed once I locate a programmer!