this week i wanted to continue my investigation into scaling up the lattice element, particularly when considering larger, outdoor applications.

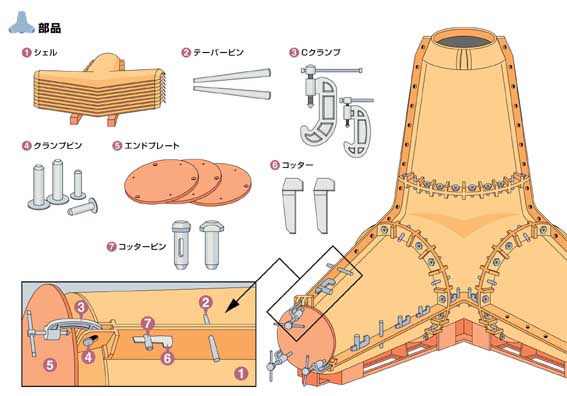

this brings me to a slight tangent on something awesome: concrete armor units.

Primarily used in coastal applications, these structures aggregate in ways that create rapid landscapes and embankments,

constructed on coasts as part of coastal defense or to protect an anchorage from the effects of both weather and longshore drift.

Their mechanical behavior at large scales is quite different: they are aggregates, relying on purely compressive forces.

This, as opposed to vertex connected lattice structures. Regardless, they are an interesting precedent.

They can be pretty big, and their "on demand" aspect is interesting, in terms of both production and deployment.

And their production technique parallels this weeks assignment.

Anyways, cool, and potentially useful as research into large scale on demand infrastructure continues. Back to molding/casting.

Looking at just a column of these lattice elements, loaded in compression, gives us the following FEA results:

In a linear elastic analysis, the diagonal members go into pure compression, while the horizontal members go into pure tension.

So, if this member were made out of concrete, or hydrostone, it would need reinforcement, due to the poor tensile strength of these materials.

At the chosen scale, some back of the envelope calculations reveal some mechanical properties and constraints:

-compressive strength of hydrostone:

10,000 psi

-cross sectional area: 1.125 in2

-compression capacity (not considering buckling): 11,250 lbs

-Force in Tension member = ~1/2 Force in Compression Member

-Fcomp= 11,250 lb, Ftens= 5625 lb

-Tensile strength grade 60 rebar: 60,000 psi

-Req'd cross-sectional area for Ftens= 5625lb/60,000psi= 0.09 in2

-Dia = 0.32" =~3/8" dia= #3 rebar

-Due to clearances, 1/4" dia. chosen, possible to use threaded rod for now.

-cross sectional area: 1.125 in2

-compression capacity (not considering buckling): 11,250 lbs

-Force in Tension member = ~1/2 Force in Compression Member

-Fcomp= 11,250 lb, Ftens= 5625 lb

-Tensile strength grade 60 rebar: 60,000 psi

-Req'd cross-sectional area for Ftens= 5625lb/60,000psi= 0.09 in2

-Dia = 0.32" =~3/8" dia= #3 rebar

-Due to clearances, 1/4" dia. chosen, possible to use threaded rod for now.

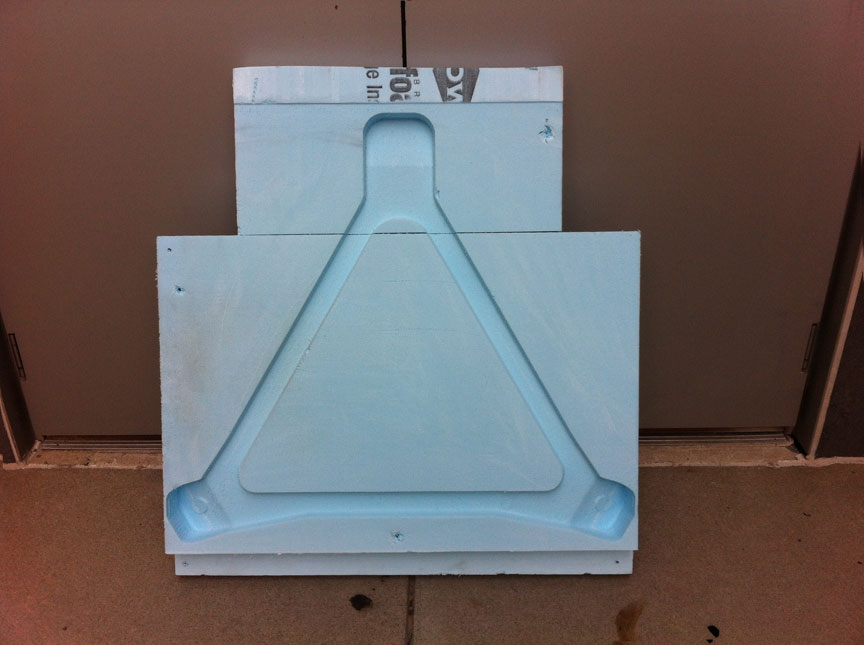

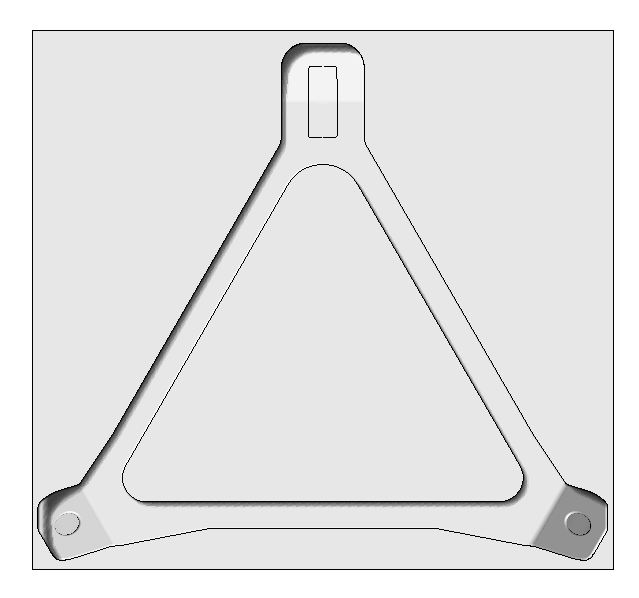

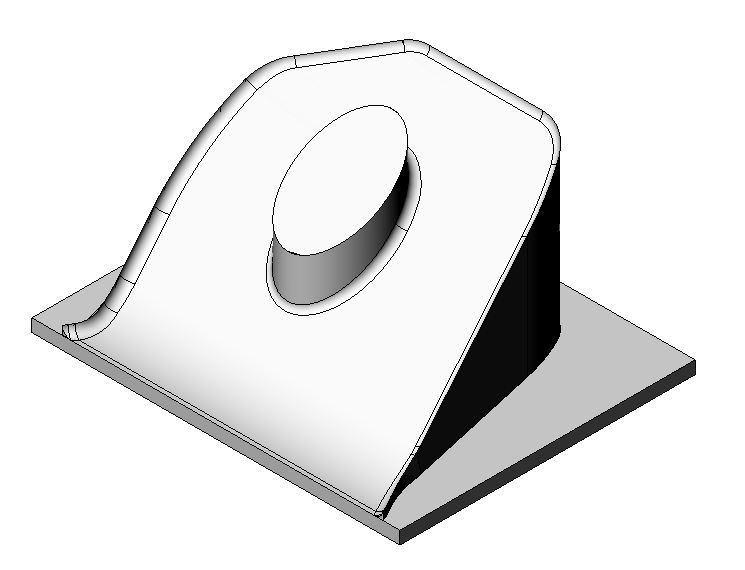

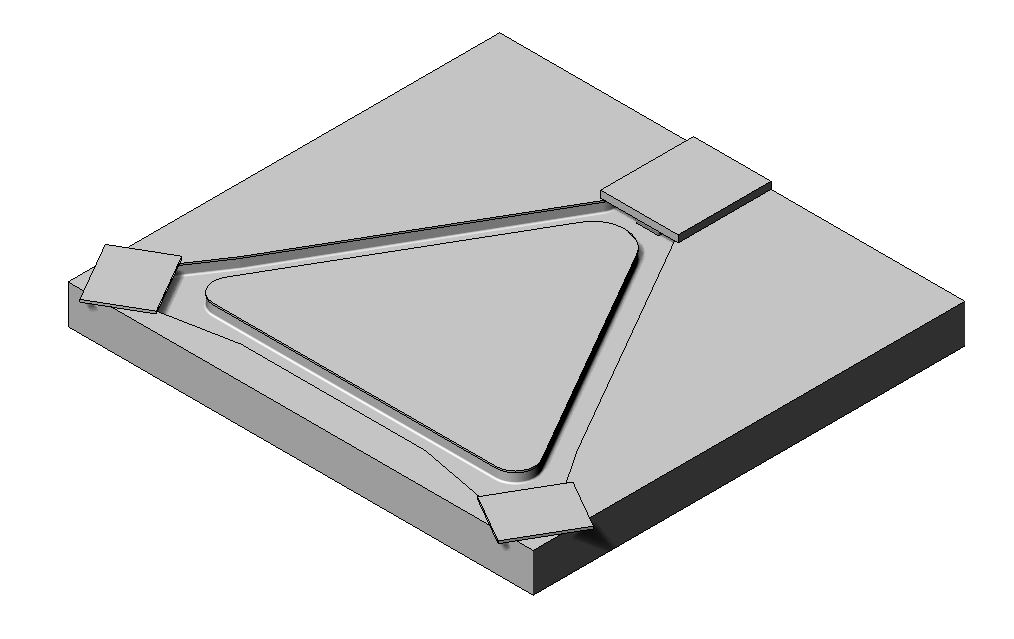

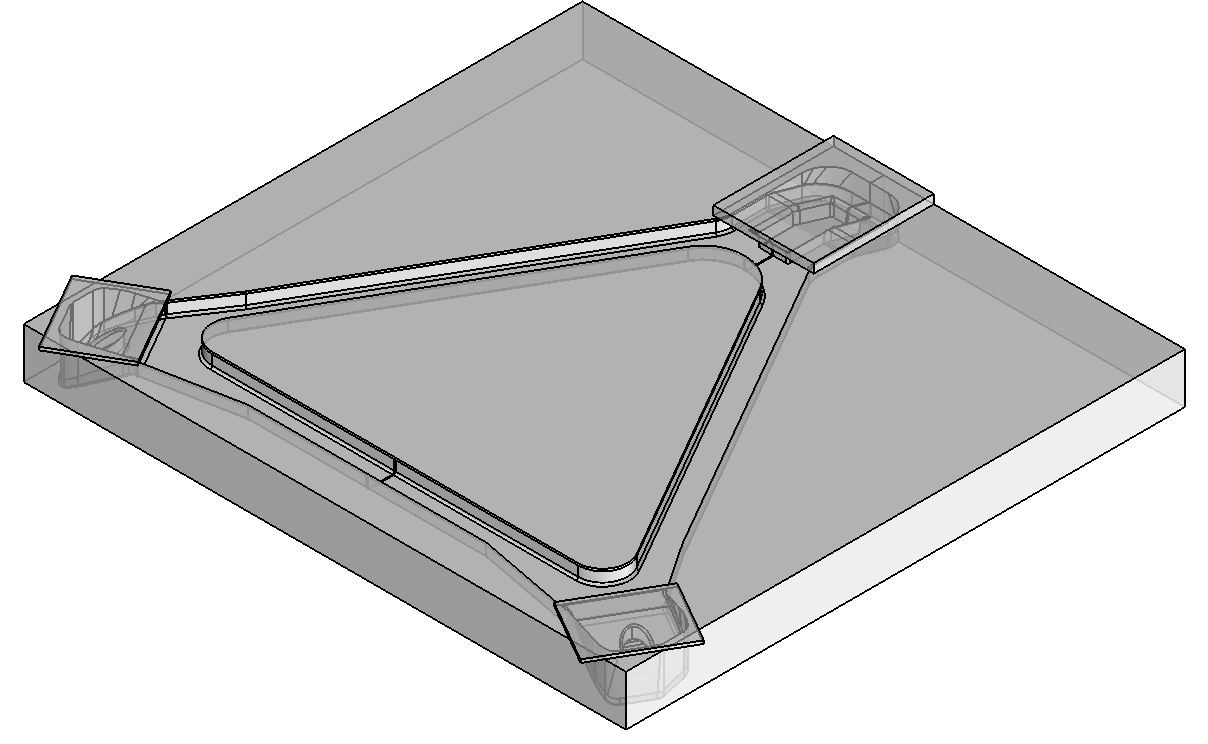

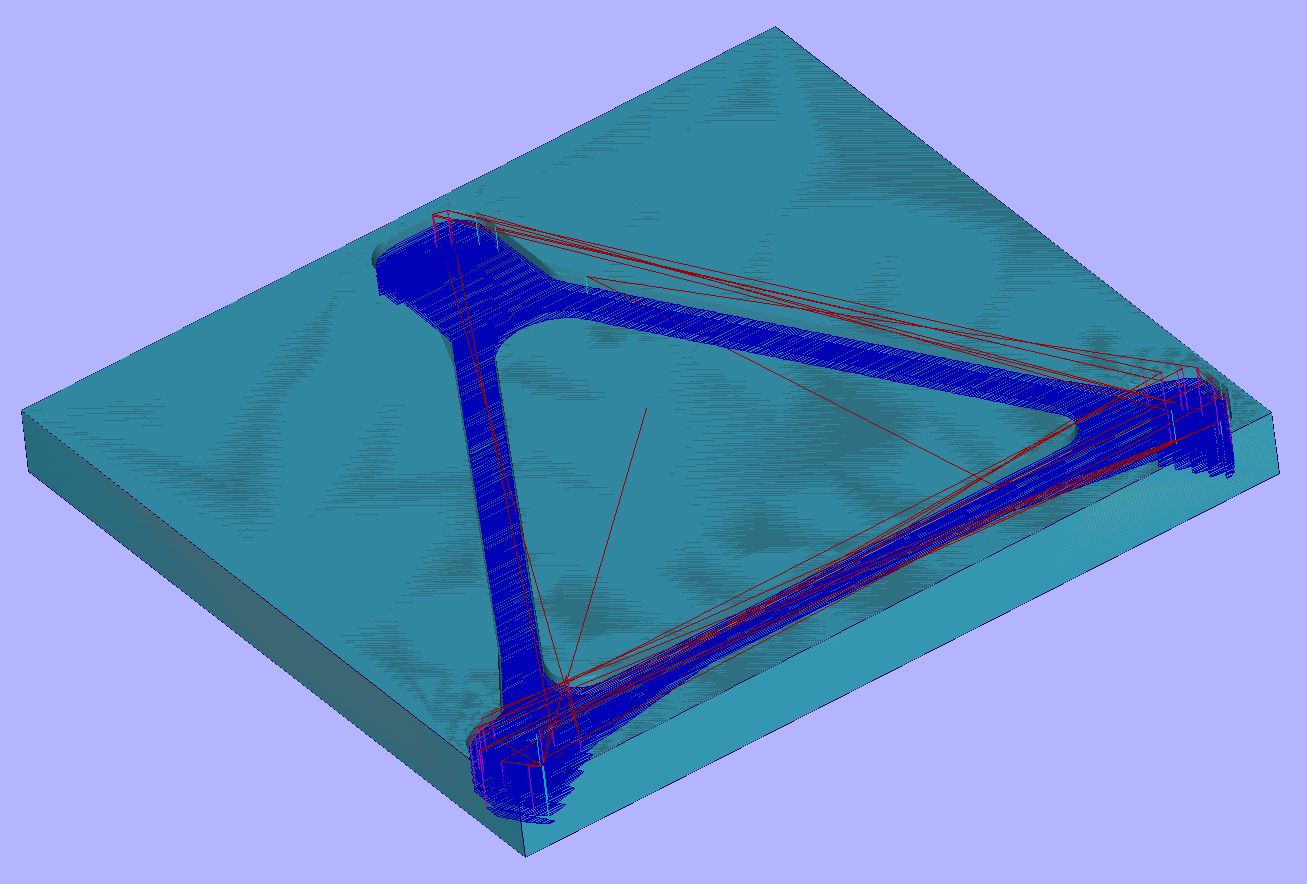

ANYWAYS, here is the

part as seen in Rhino. The plan is to use a "1.5 part

mold" approach:

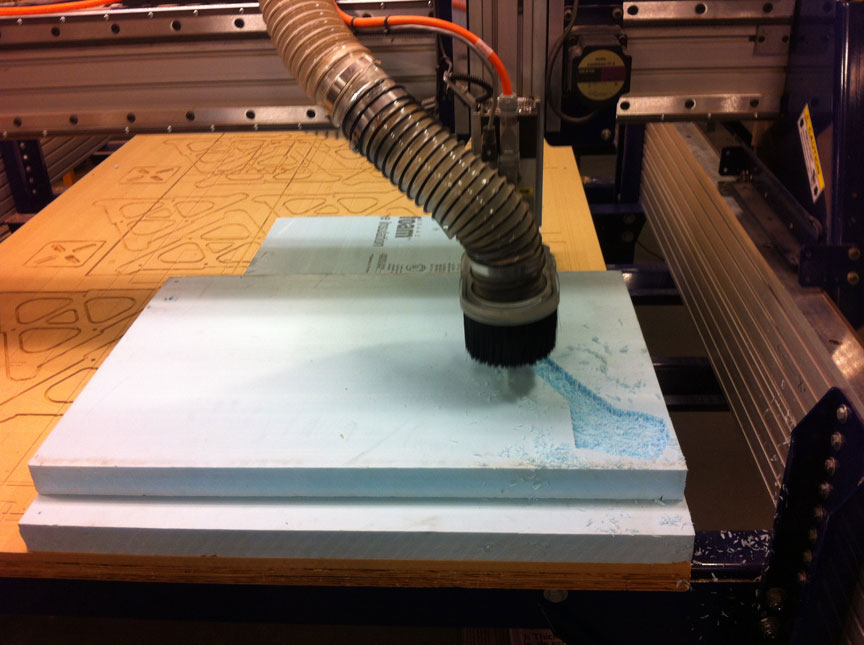

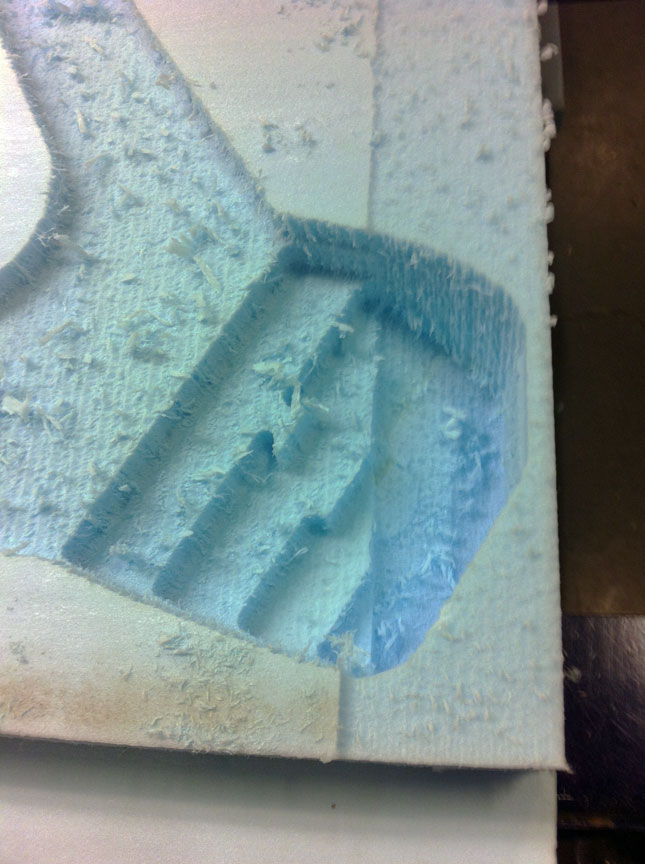

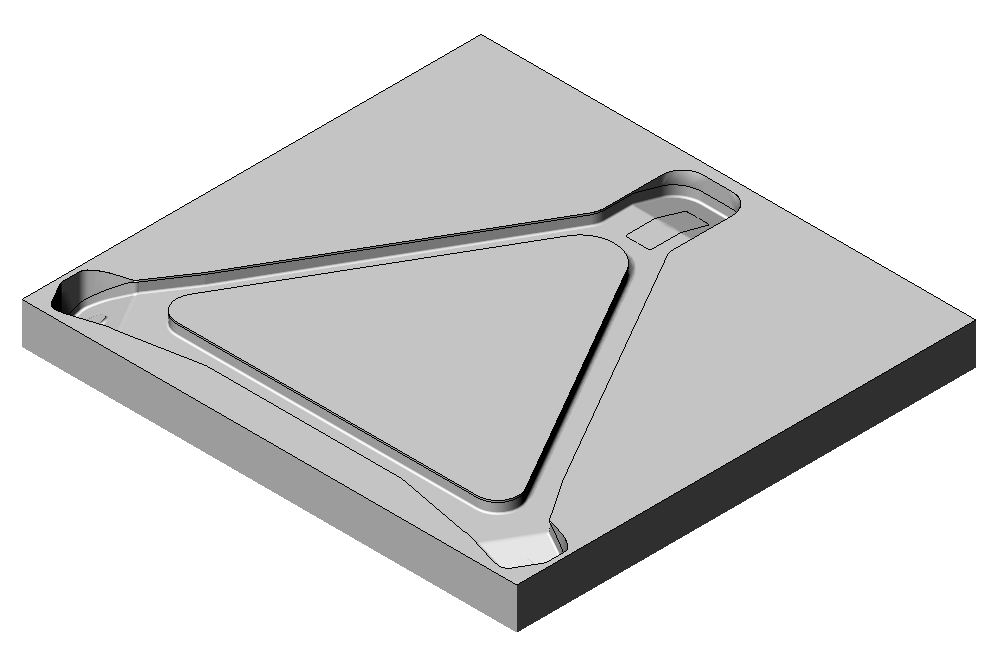

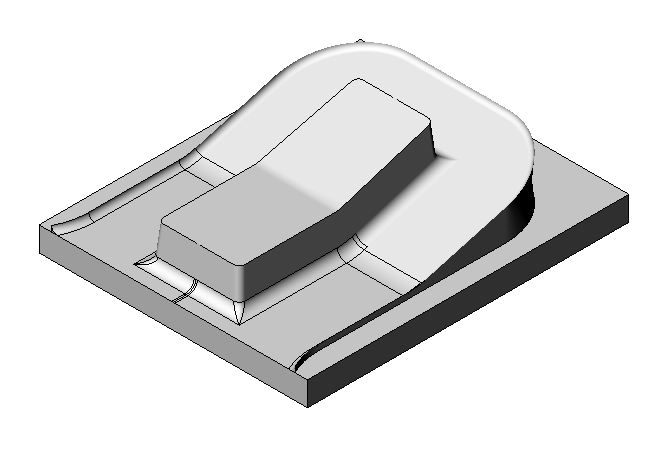

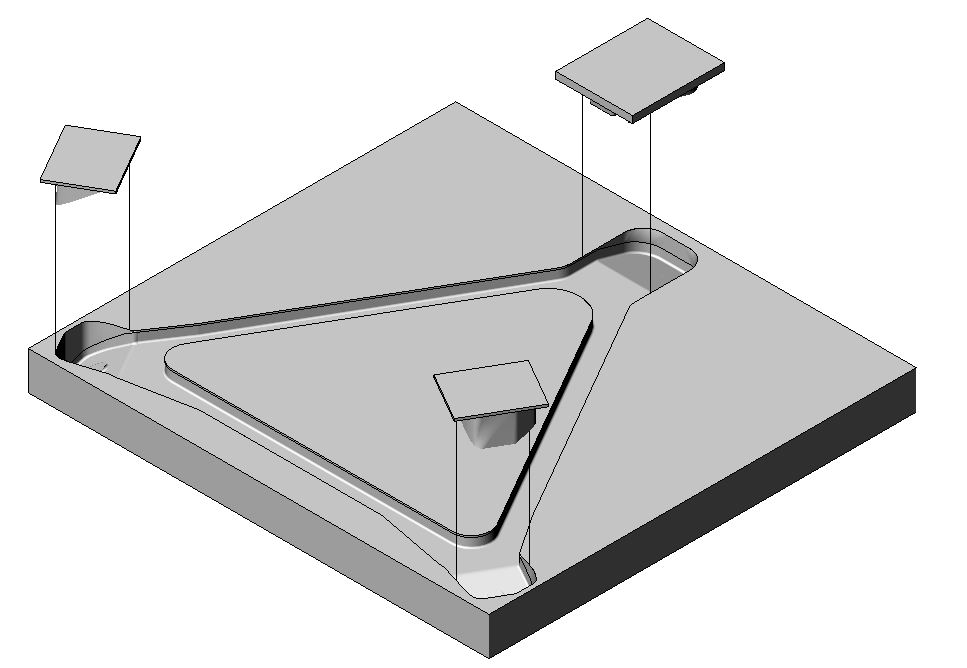

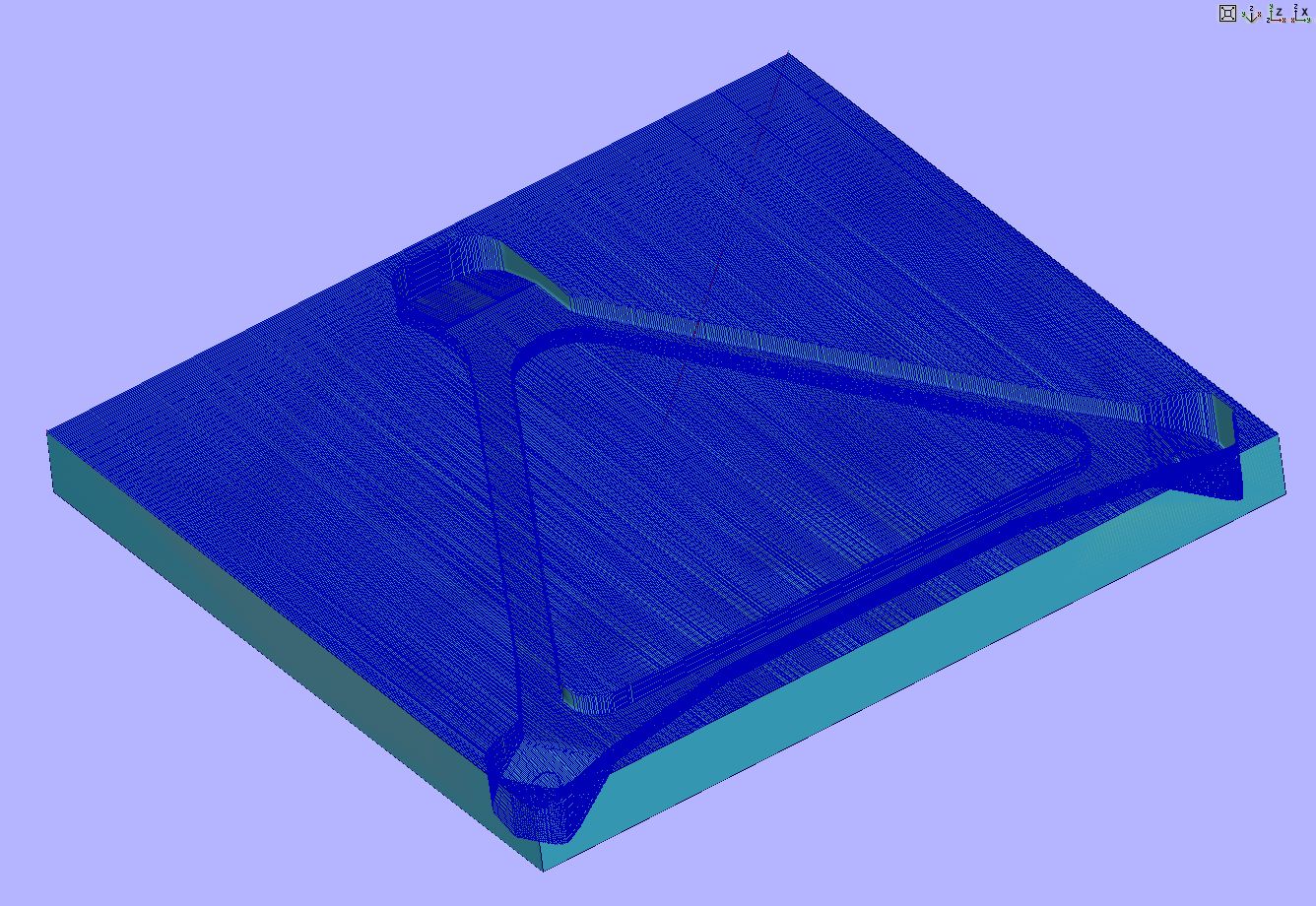

One of the main problems with toolpathing was the finish toolpath- I wasn't able to get a toolpath only within my specified geometry, the software defaults to a blanket finish path, which added several hours. I imagine other softwares are more customizable, so I will look into this in the future.

One of the main problems with toolpathing was the finish toolpath- I wasn't able to get a toolpath only within my specified geometry, the software defaults to a blanket finish path, which added several hours. I imagine other softwares are more customizable, so I will look into this in the future.

Milling was easy- 1/4" ball nose, 6000 rpm, upwards of 250 in/min