my main experience with input devices is with load cells, primarily for mechanical testing of material coupons, normally with an instron machine

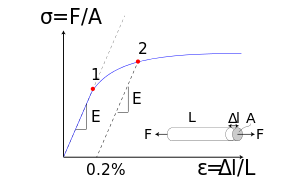

which gives you a readout of the force being applied (tension or compression) and the strain (elongation/original length).

Sometimes you can get away with a rough approximation of the strain, but other times you want accuracy so you use a strain gauge

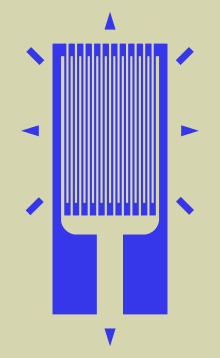

As the gauge is deformed, its electrical resistance changes due to deformation of the thin strips of conductive foil.

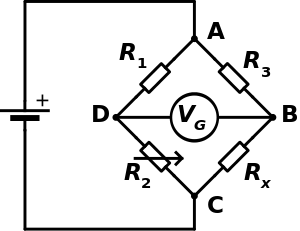

When this resistance change is measured on a Wheatstone bridge, it can give the strain by using the "gauge factor".

Anyways, I was interested in using strain gauges as the input device,

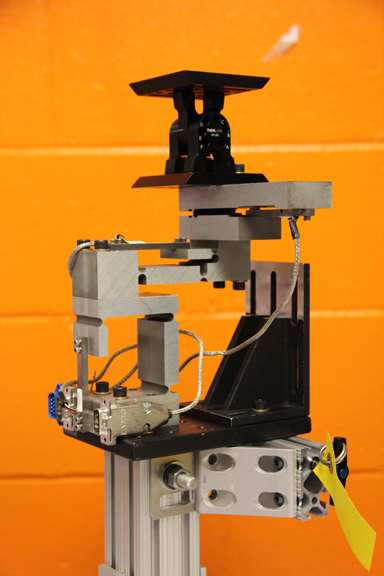

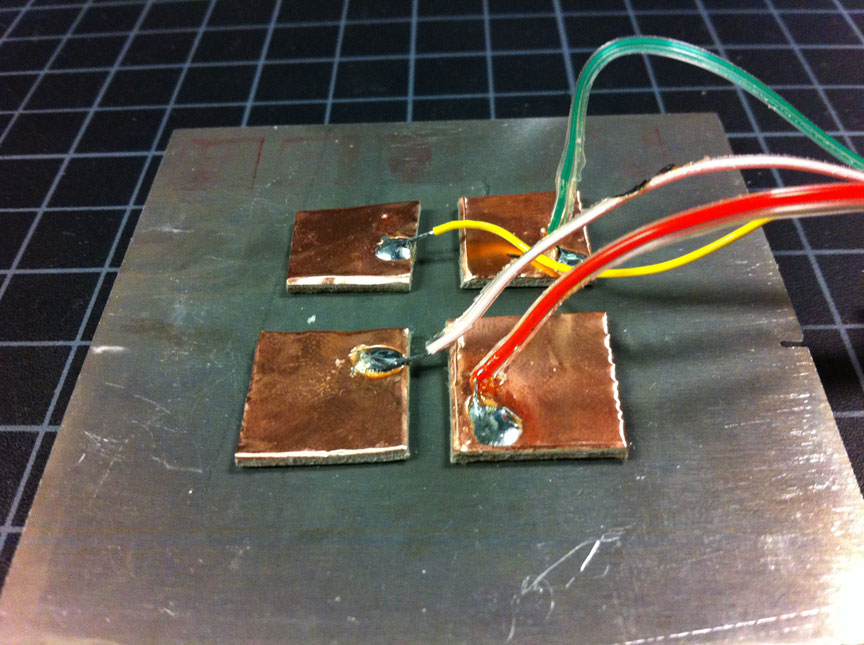

and I was inspired by this 3 DOF load cell I helped build for recent experiments in the MIT wind tunnel

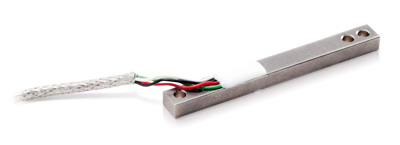

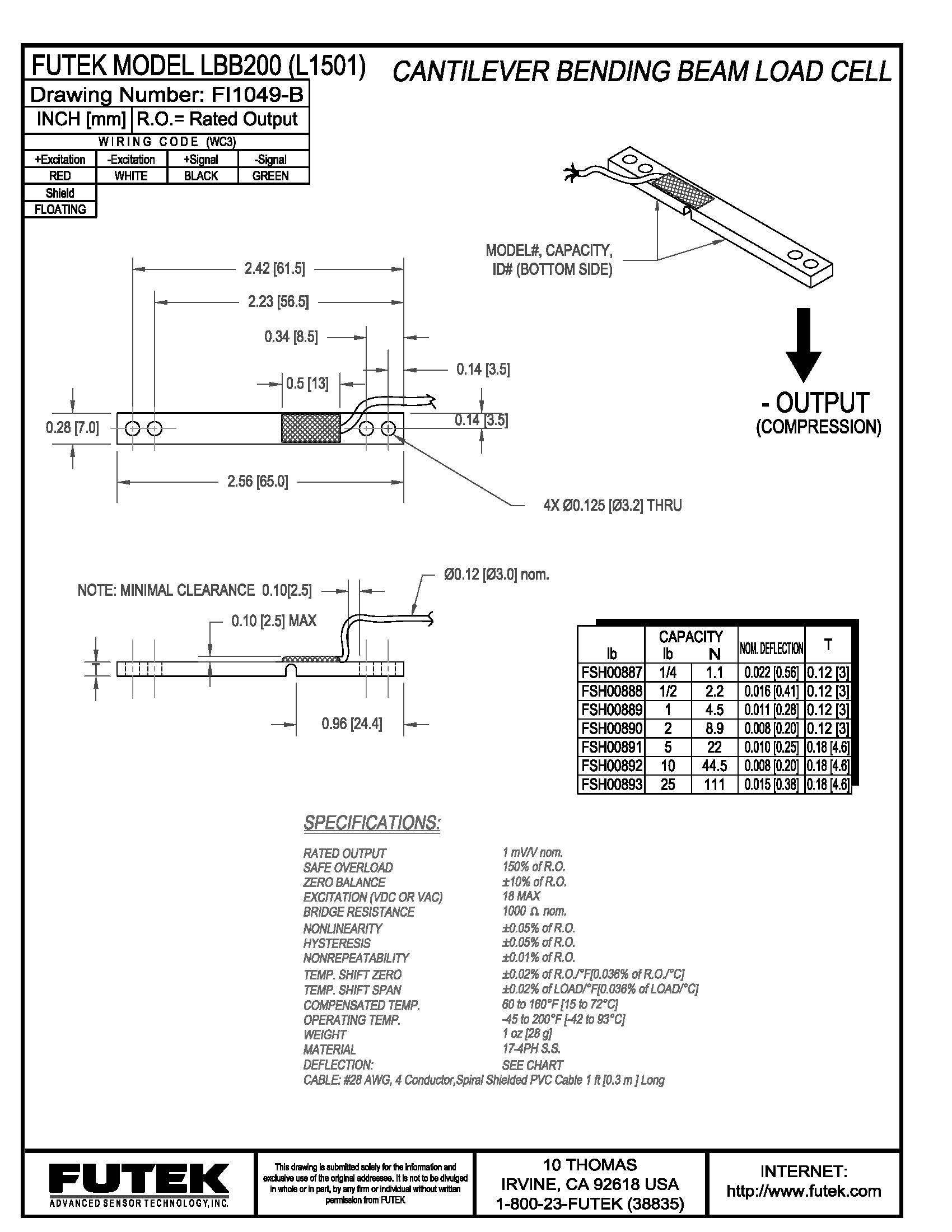

The strain gauges used here are FUTEK LBB200

Because of this 4 wire output, I figured it could be compatible with the 4-pin input and be feasible to read as an input device.

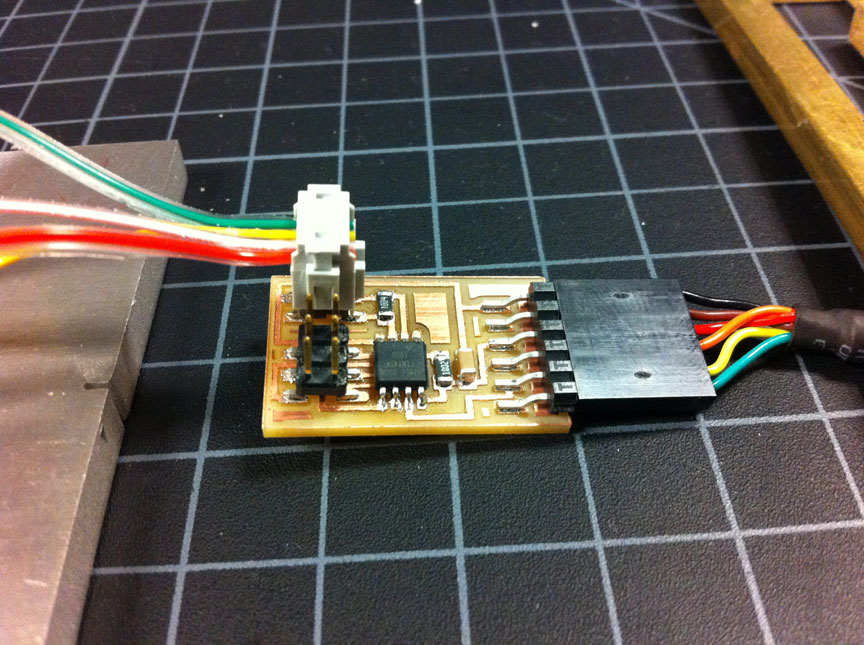

However, as is normally the case with strain gauges, a signal amplifier is needed. This is recommended:

AD7781 20-bit, Pin-programmable, Low Power Sigma-delta Adc

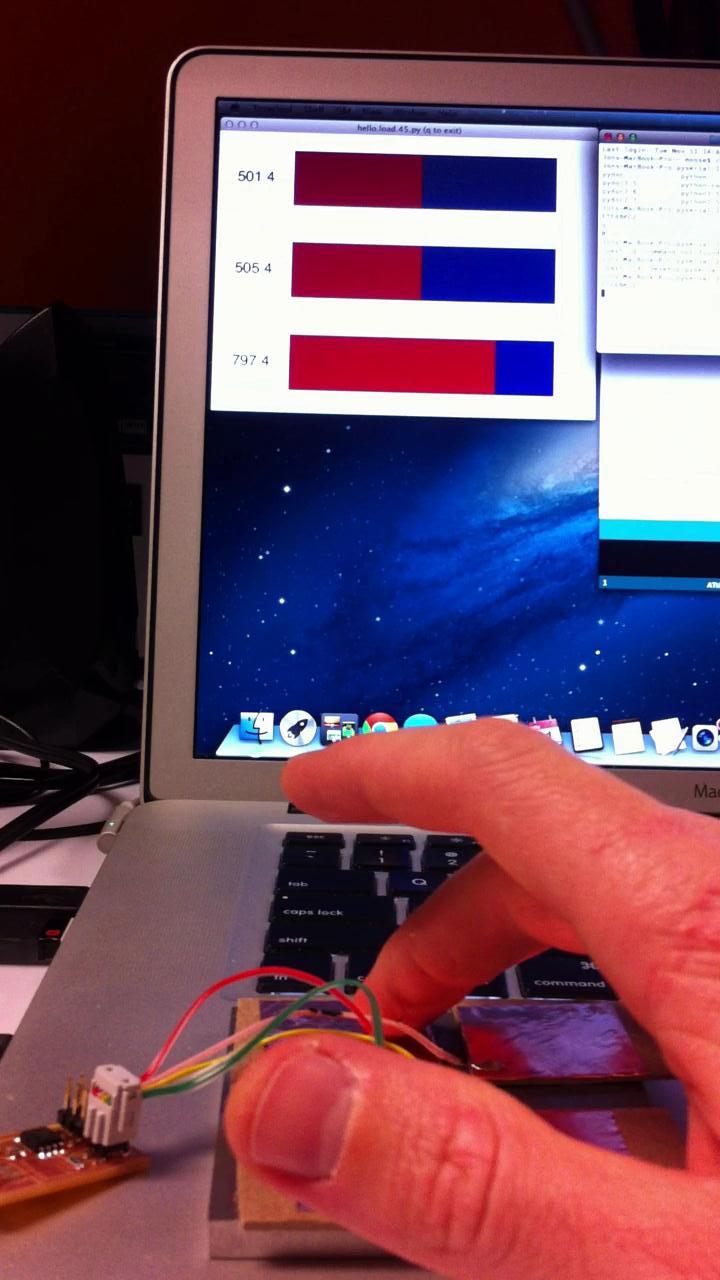

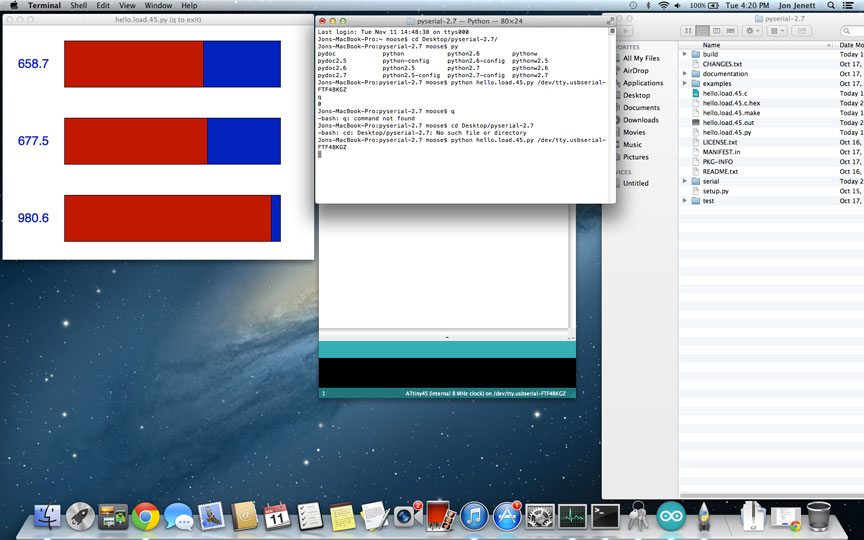

Before jumping into this, I wanted to do a "hello world" test with the loading step response board

click picture for video

Now that I have gone through this, I am planning on using the vinyl cutter to cut flex circuits for strain gauge sensing.

It will be possible to verify their functionality without an amplifier using a benchtop multimeter that can probe in the ~uOhms range