How to Make (Almost) Anything

Project 07

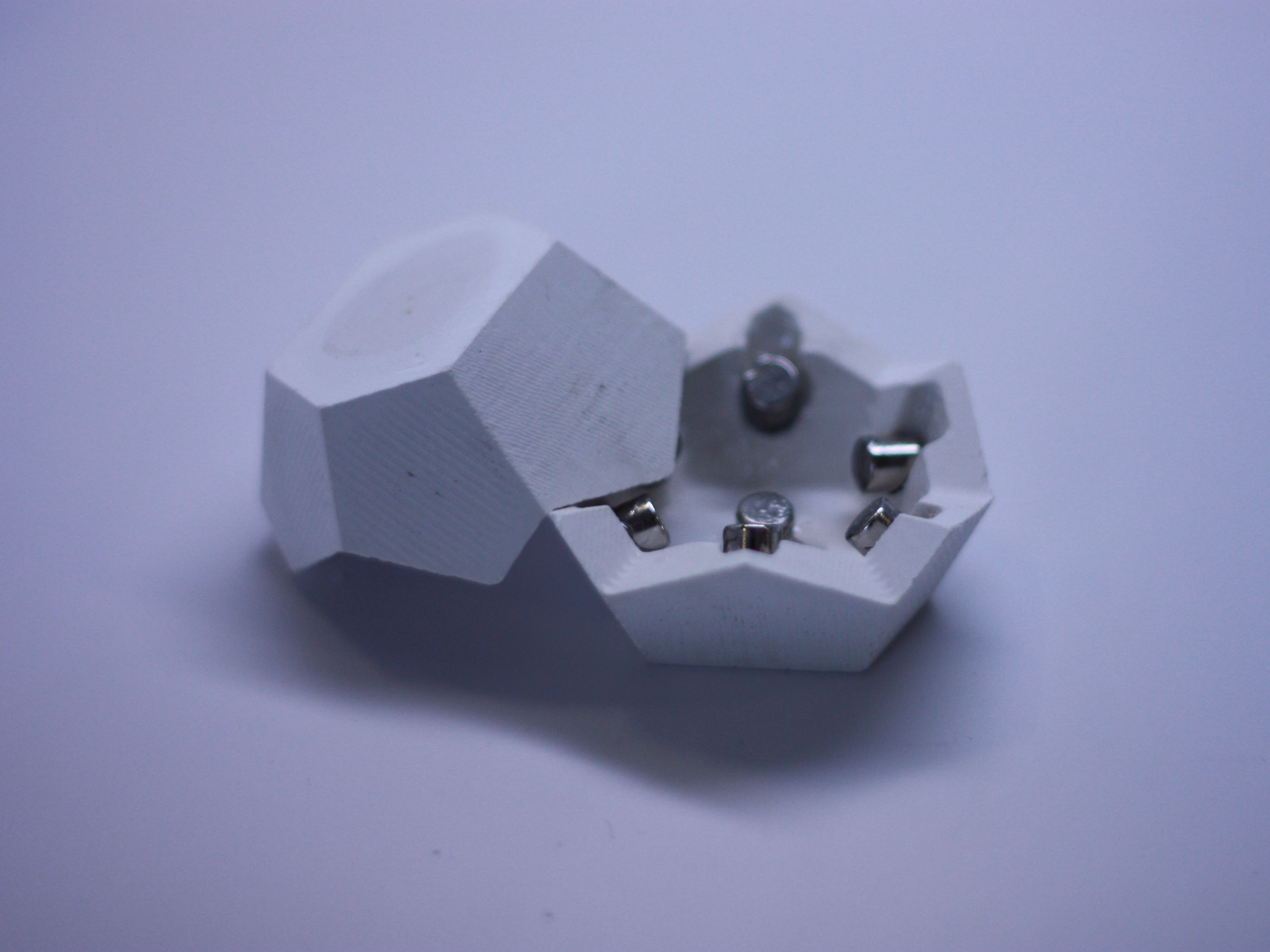

Topic: Molding and Casting

<1>

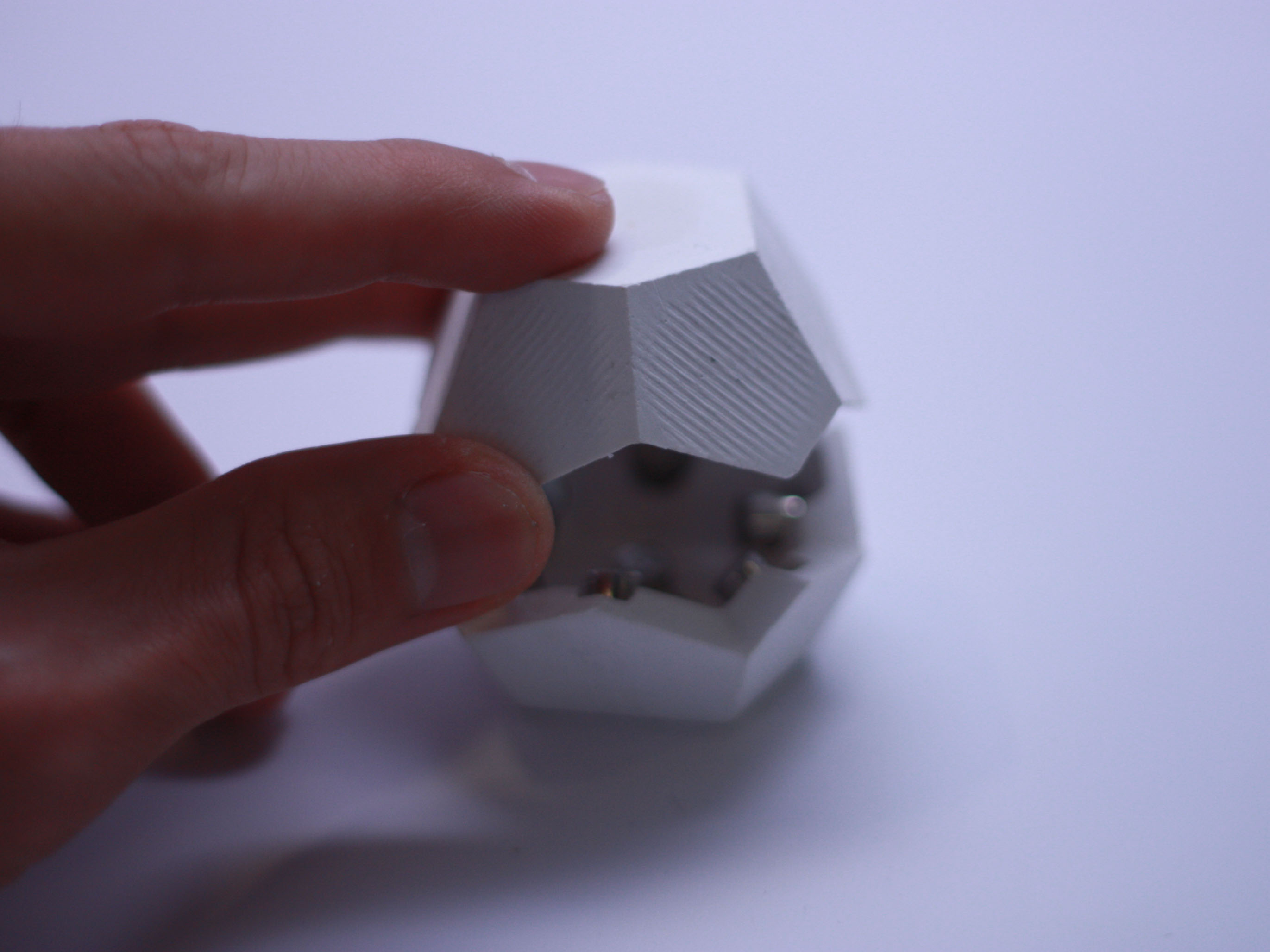

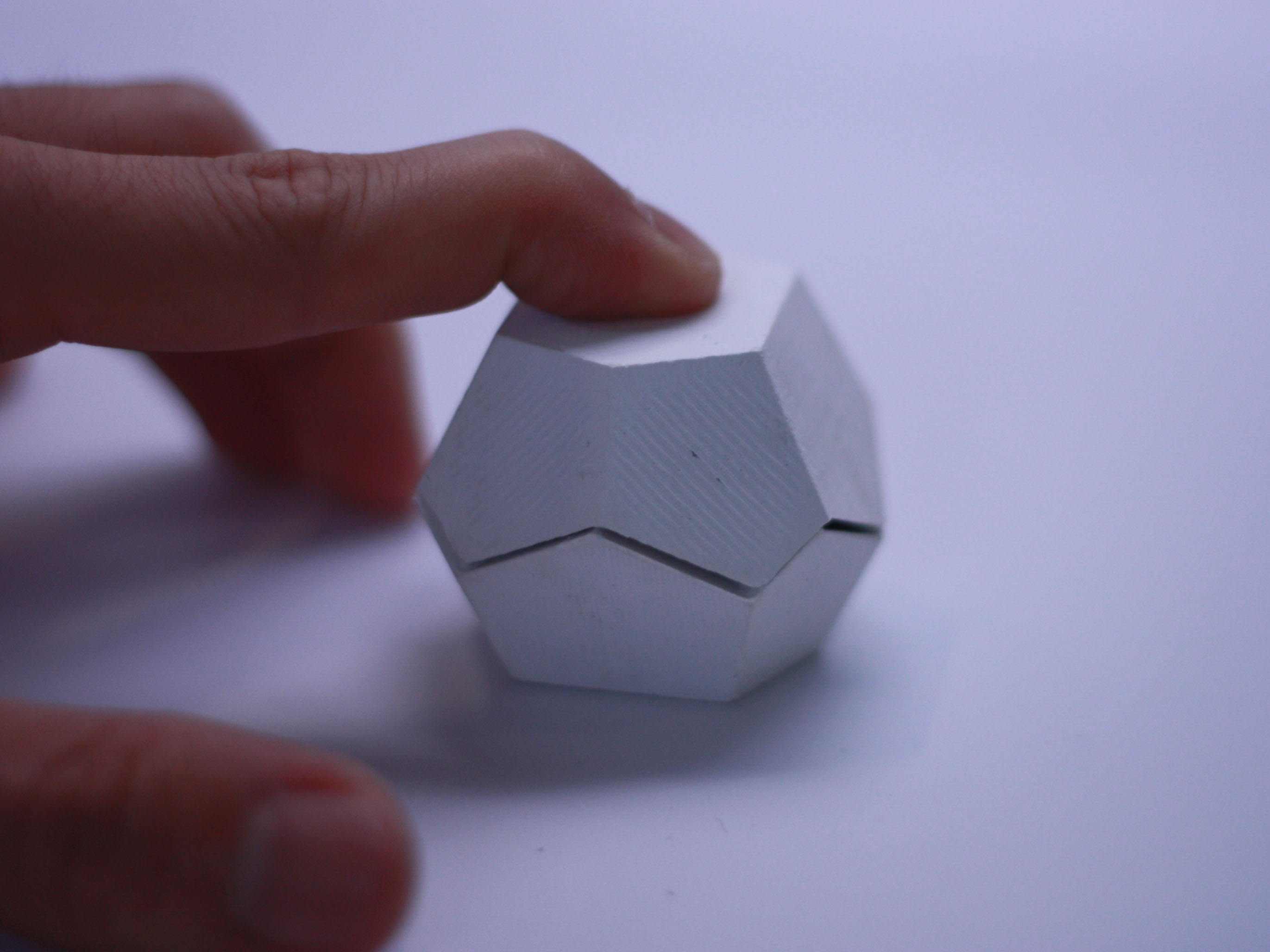

Design: Weaire-Phelan Structure (The Water Cube)

Software: Rhinoceros 5.0

Hardware: Shopbot 3-Axis Milling

Material:

Machinable Wax:

<1>

- Melting Point = 240 F

- Specific Gravity = 0.92

Silicone Rubber / Eleastomer (OOMOO(R) 25/30):

<1>

- Melting Point = None (It burns at the following maximum service temperature)

- Service Temperature > 300 F

- Specific Gravity = 1.18

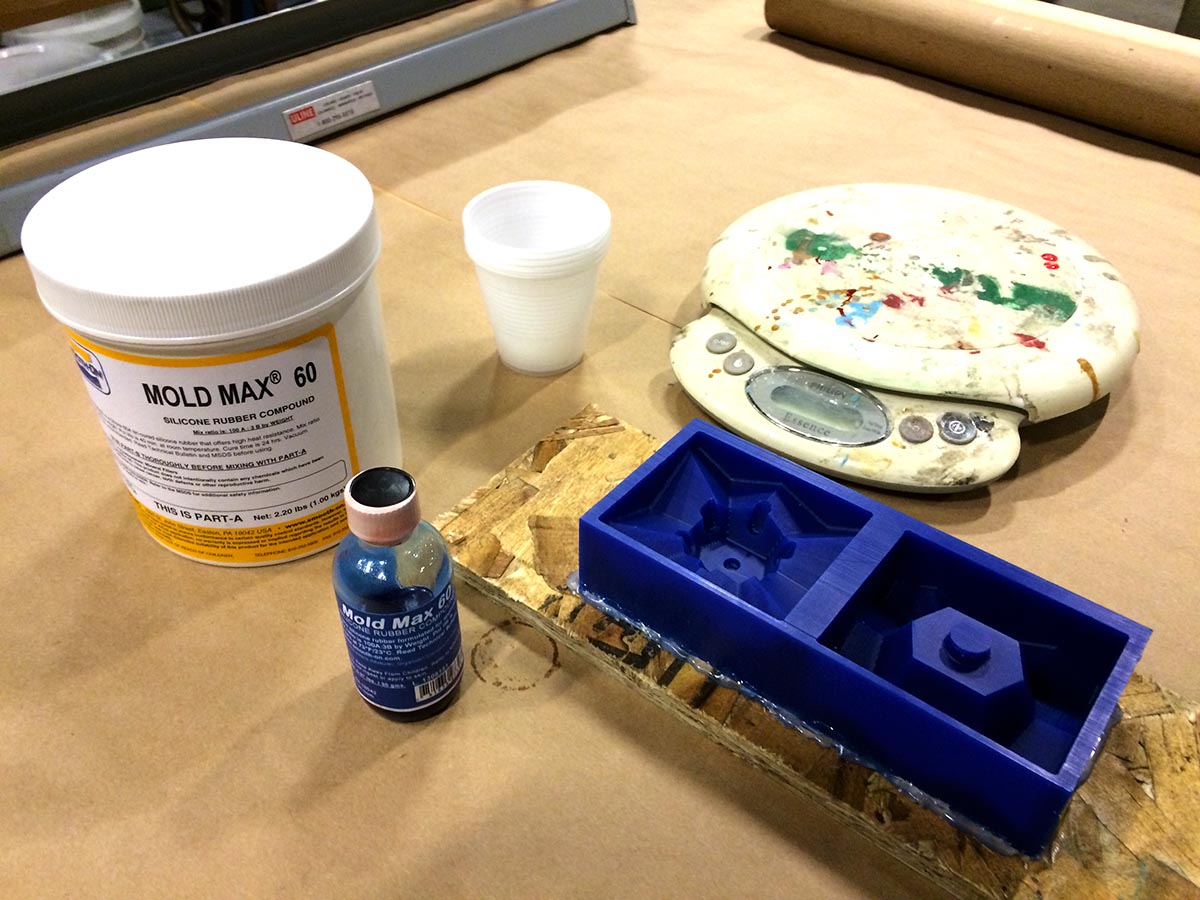

High Heat Resistant Silicone Rubber (Mold Max(R) 60):

- Maximum Service Temperature = 300 C (560 F)

Plaster:

<1>

- Melting Point = 1200 C (2200 F)

- DryStone

<1>

- HydroStone

<1>

Babbitt Metal (White Metal):

<1>

There are many alloys (a material composed of two or more metals or a metal and a nonmetal) of babbitt metals. In general, babbitt metal is made of metal alloy that is soft and low in melting temperature.

- Melting Point = 240 C (460 F)

- Proper Pouring Temperature = 425 C (800F)

Variation of Babbitt Metal Alloy:

- Nickel Genuine = 90% Sn(Tin) + 3% Cu(Copper) + 7% Sb(Antimony)

- Super Tough = 85% Sn(Tin) + 7.5% Cu(Copper) + 7.5% Sb(Antimony)

- Heavy Pressure = 10% Sn(Tin) + 75% Pb(Lead) + 15% Sb(Antimony)

Tutorial:

- Casting Metal Babbitt:

<1>

- Plaster Mold Casting:

<1>

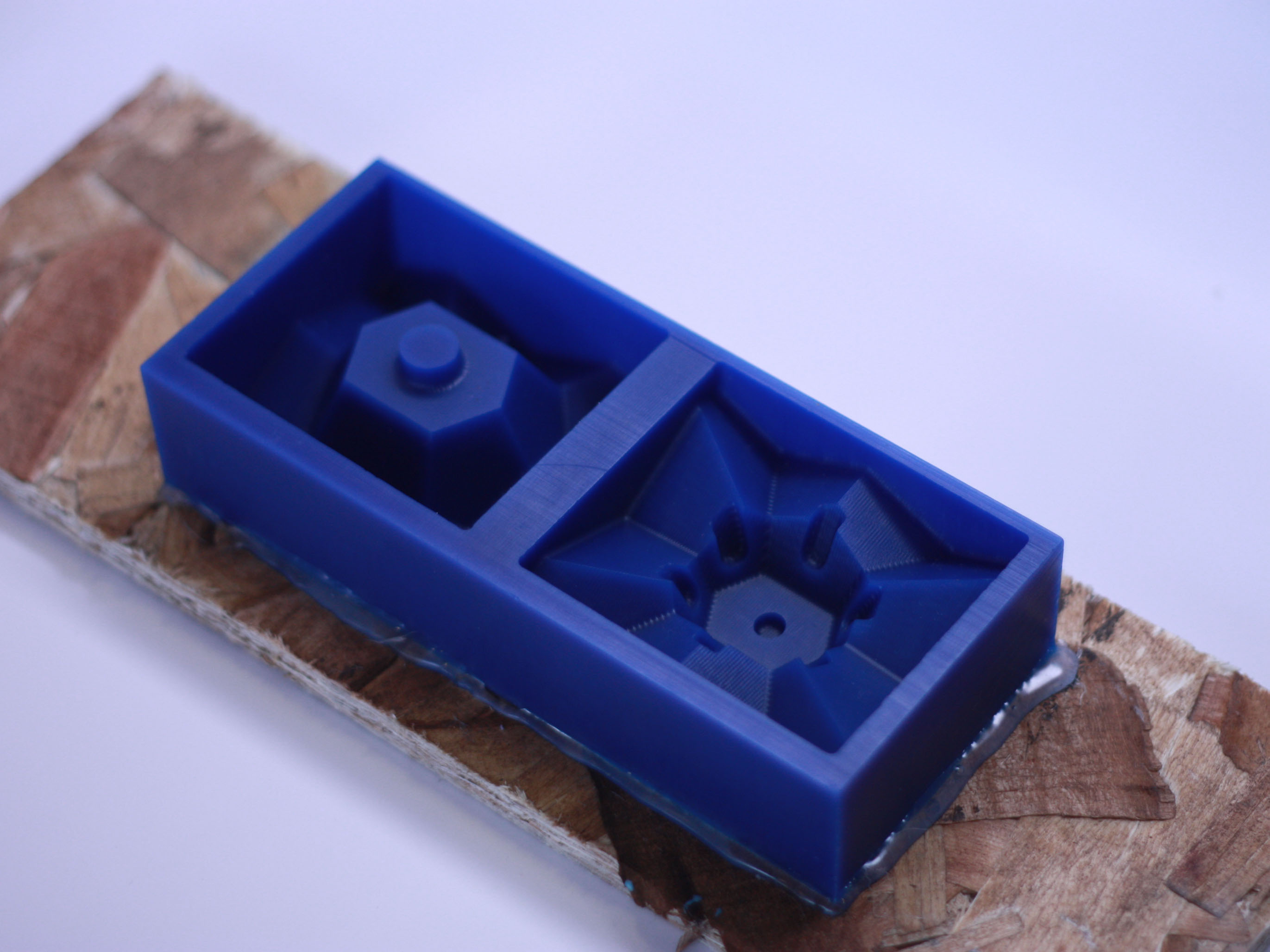

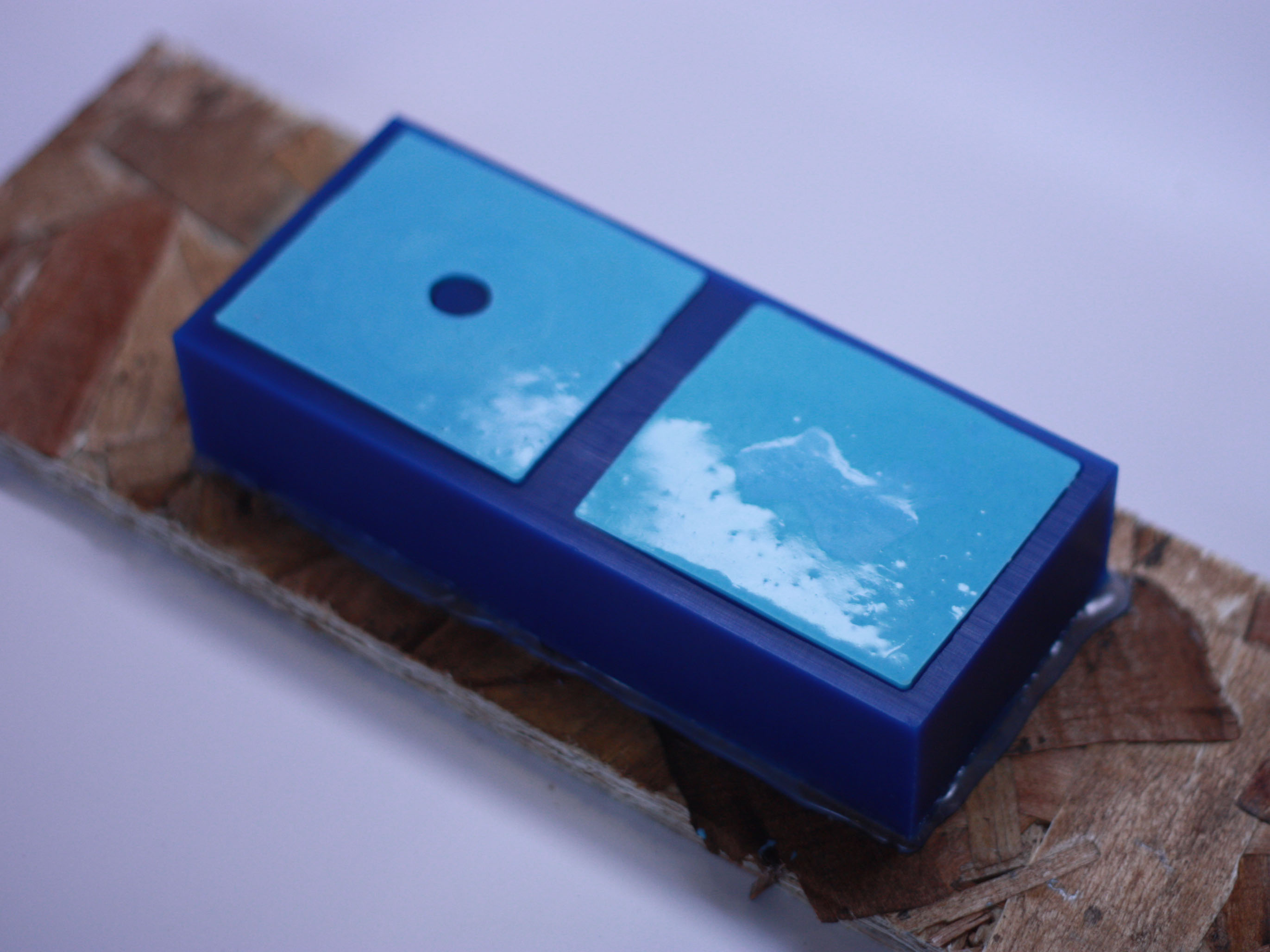

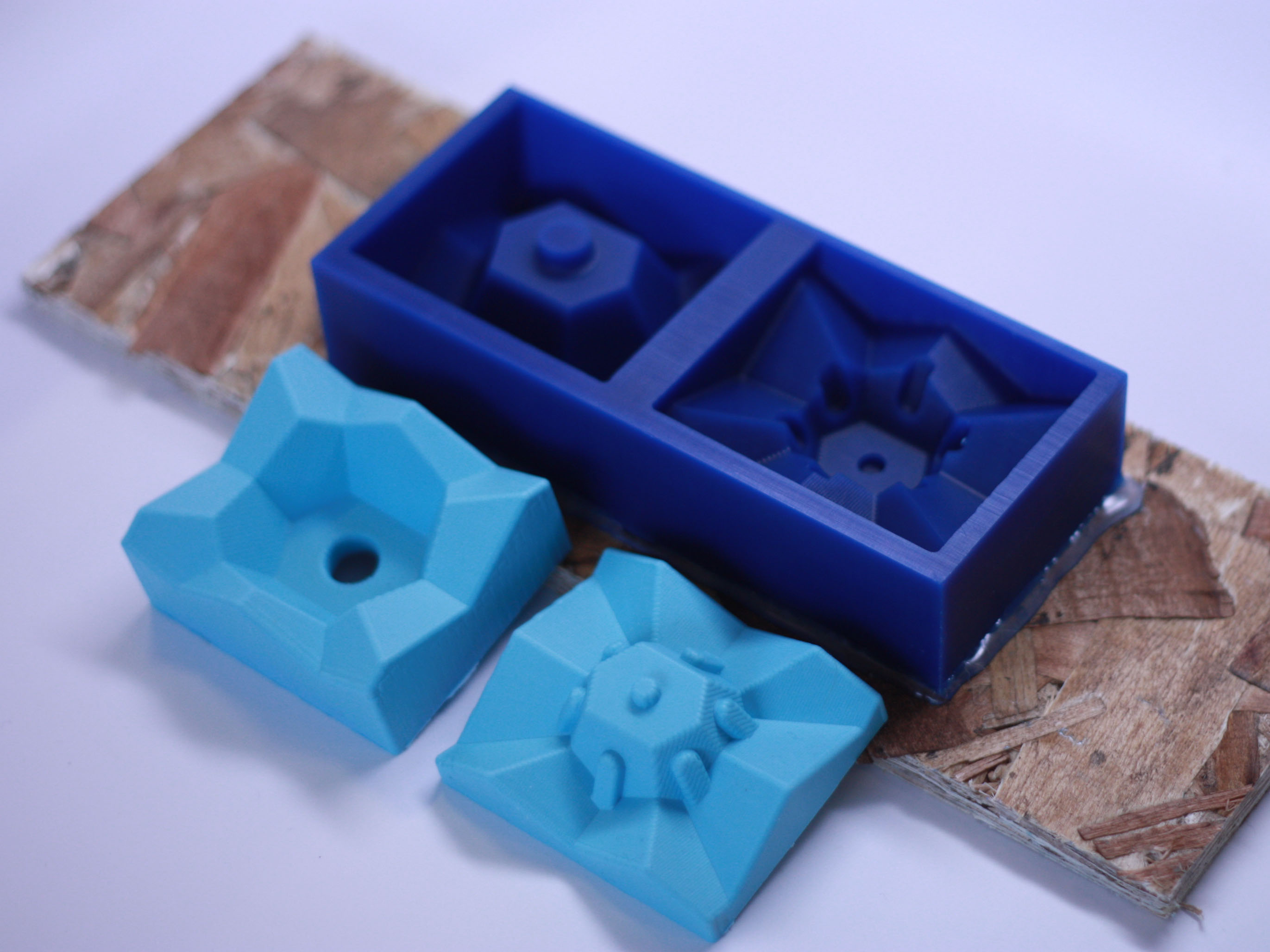

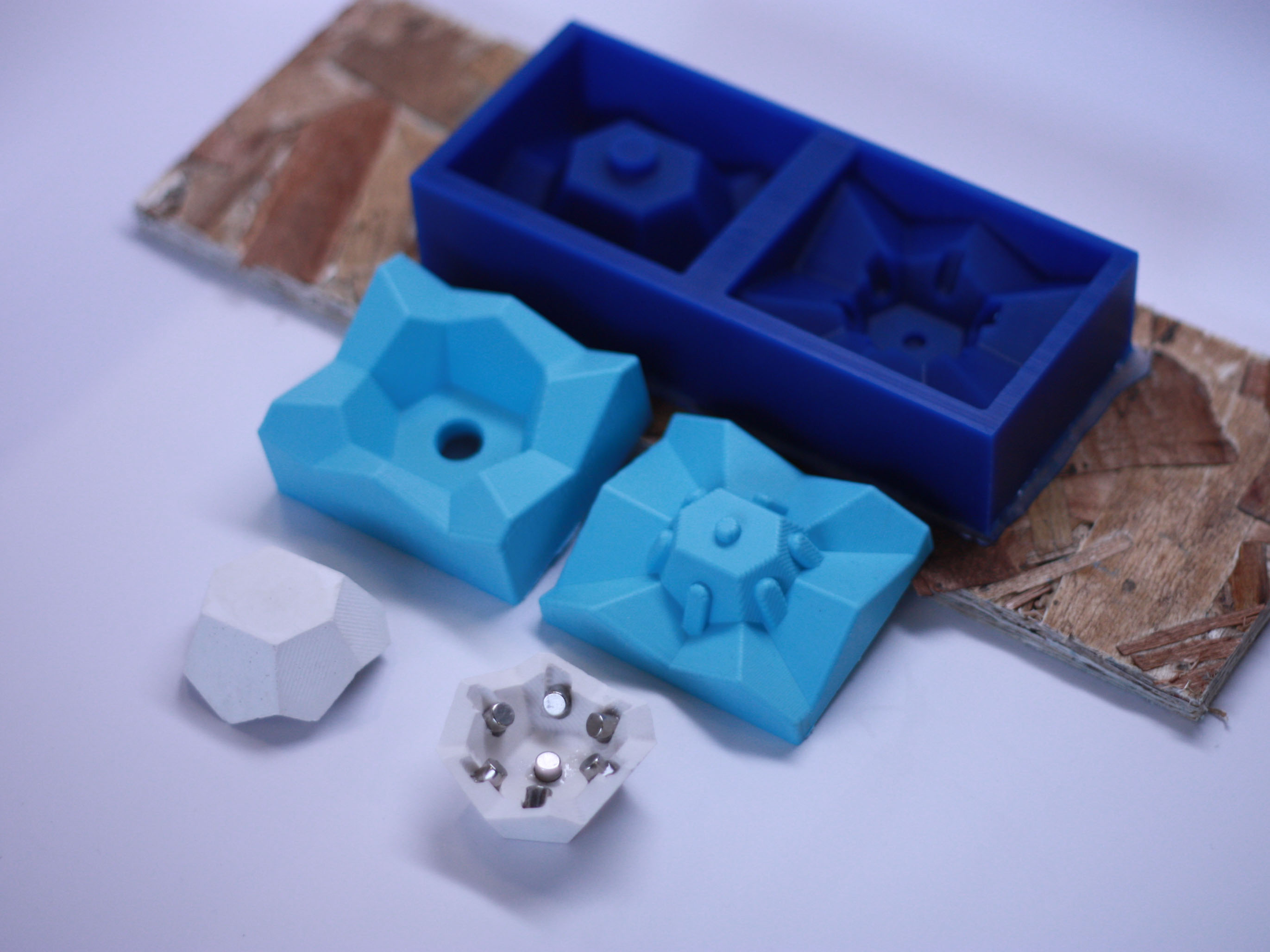

Wax + Silicone + DryStone:

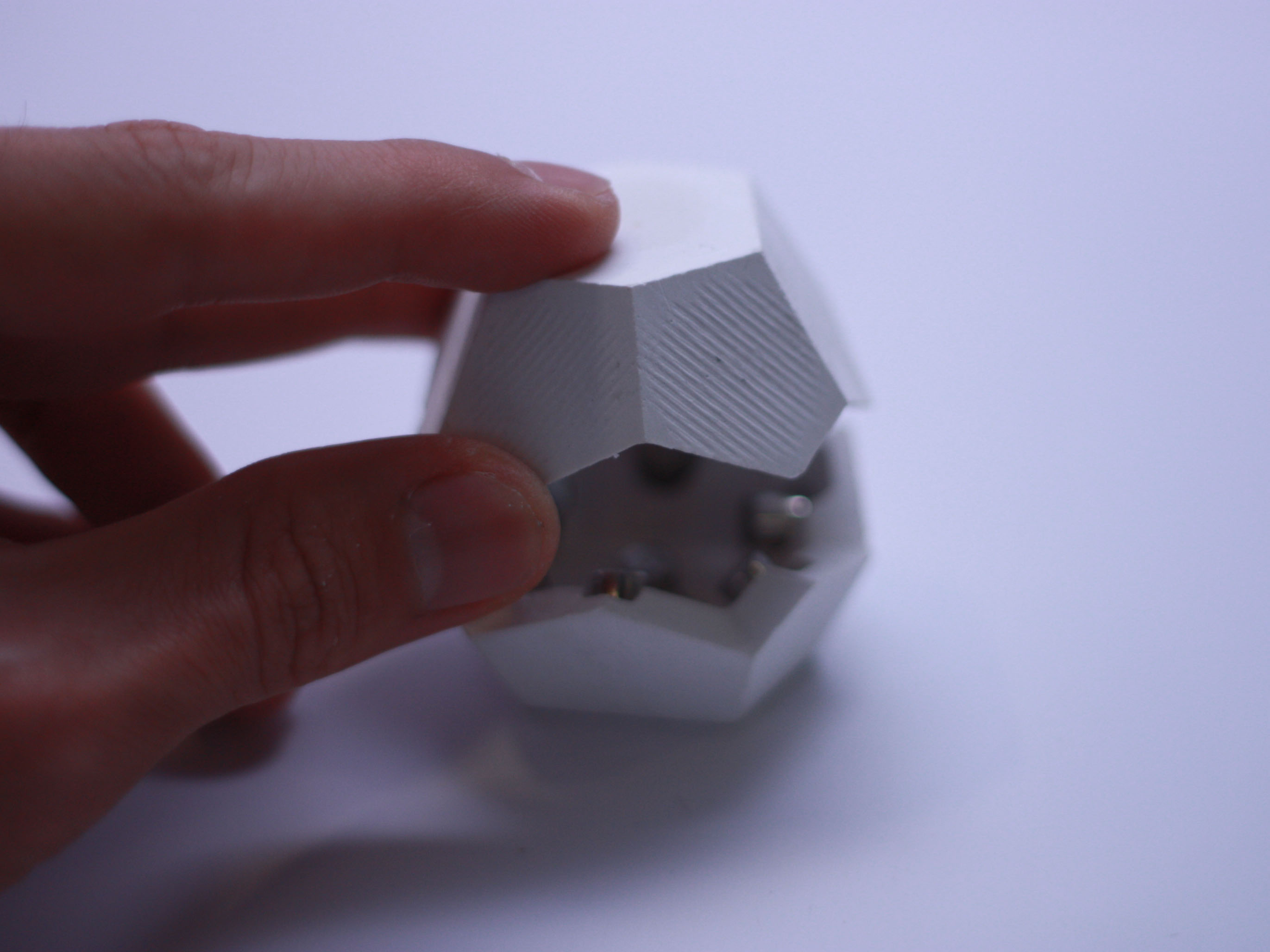

High Heat Resistant Silicone + Babbitt Metal