3D scanning was pretty disappointing. I 3D scanned an RC plane controller, but the result was unimpressive (rather lumpy), and the file was so large I couldn't transport it feasibly. Thus no evidence remains...

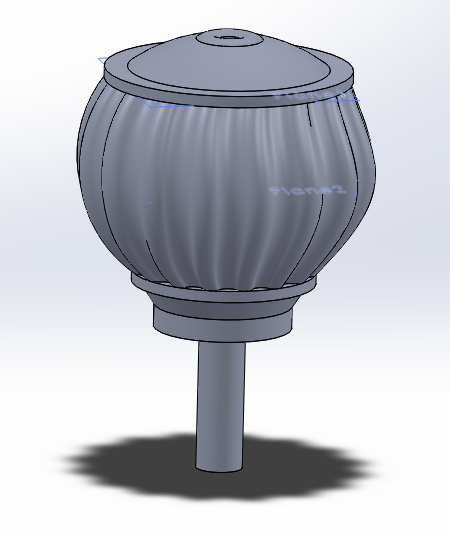

3D printing was much more rewarding! I needed some knobs for a drawer that was missing its originals. I designed them in SOLIDWORKS.

A triply-guided loft and some revolutions.

I wanted it to look real Victorian ornamental, like some fancy cast crystal knob.

It took some wrestling to get it ready for printing. First, it needs to be converted to .stl format. I opened it in eDrawings, a free tool which comes packaged with SOLIDWORKS (thank goodness), and saved it out as an STL. Make sure the units stay consistent, or you may have some scaling to do later.

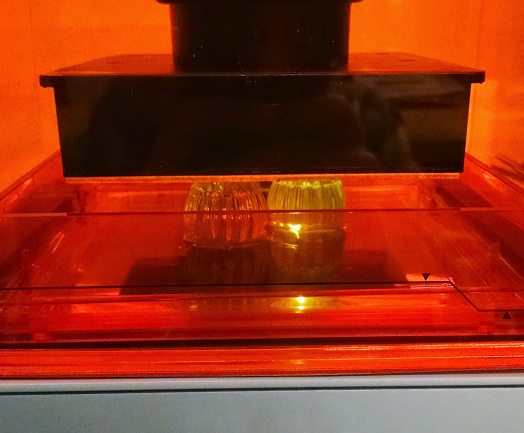

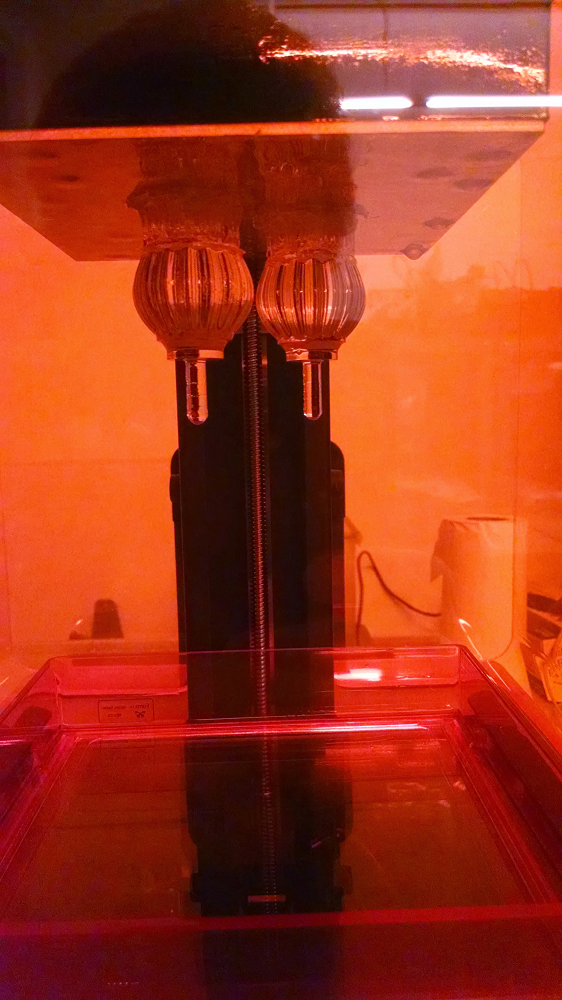

The Form 1 is really cool.

The Form 1 is really, really cool.