Design was in SOLIDWORKS. Again, I used parametric design.

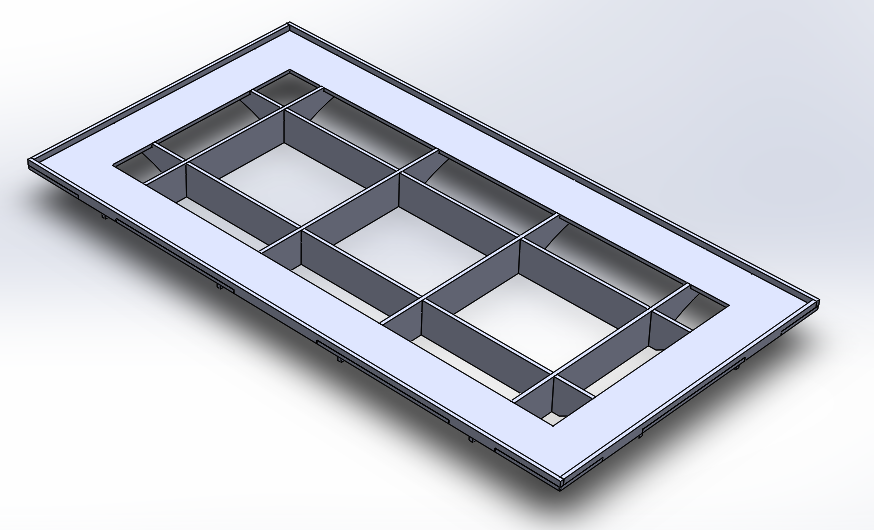

Here's the SOLIDWORKS model.

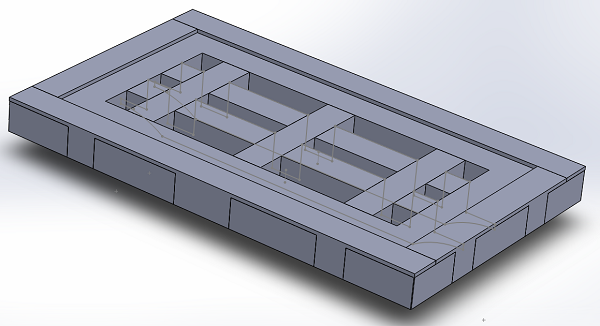

Just to demonstrate the parametric model, here's a rebuild with unrealistically thick material--all the geometry still works out for assembly.

The ShopBot at work...

All parts accounted for.

Note the T-bone extensions on each of the slots designed to accept a tab. Without these T-bones, the tool would not be able to mill the corners of the (exactly sized) slots, and the pieces would not fit all the way together.

T-bones allow enough room for corner-mating parts to fit together.

Fully assembled, waiting for glue to dry.

Glue holds the outside edges onto the large rectangular frame, but the fit at the joints was tight enough that the whole assembly can be broken down in less than a minute into a flat-pack configuration for transportation.

That's how I got it home. At time of writing, it's my bed frame!