I decided I wanted to investigate the mechanical properties of silicone rubber, in case it might be useful as a spring element in my final project. The original aim was to make a variety of even-profiled projections out of the rubber, and test the stress required to deform them with a load cell.

I created a negative mold. My design started in Inkscape, from which I exported a .png image. From there, the Fab Modules transformed it into a toolpath for the Modela.

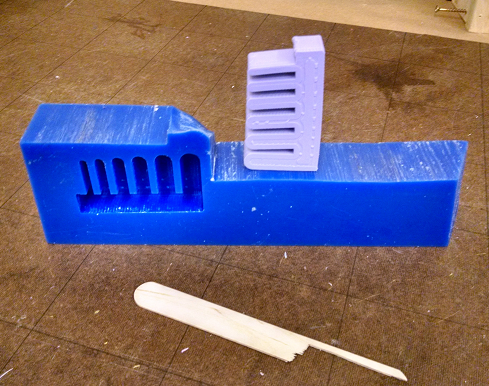

The negative mold, fresh from the Modela, and the Oomoo components ready to mix at a 1:1 volume ratio in separate cups.

24 hours later, yes, the rubber is firm-- in fact, firmly stuck in the mold!

Released from the mold

It took a long and patient encounter with the tool pictured below, a carefully fractured tongue depressor, to free the rubber object from the mold.

Very squishy rubber.

The rubber turned out to be significantly flimsier than I had expected, so I abandoned that line of investigation. I still think it would be cool to mill a Wheatstone bridge out of a double-sided PCB to make a load cell, though.