This week I’ve been watching and helping others use the ShopBot more than using it myself. The experience leads me to eschew the OSB in favor of foam core board.

A recent conference left scores of 1/2″ thick 5’x8′ foam core boards, some ten of which were saved as stock. The ShopBot Buddy can cut a 4’x4′ piece, so I used that as my size limit for making a truncated icosahedron, or soccer ball shape.

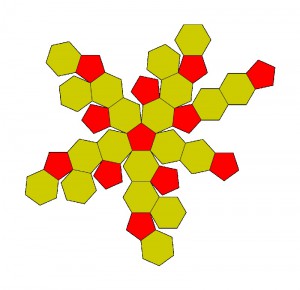

I downloaded an unfolded net of the shape from http://en.wikipedia.org/wiki/Truncated_icosahedron, with an eye to identifying the subsets of faces to cut from my board.

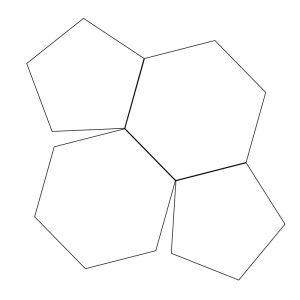

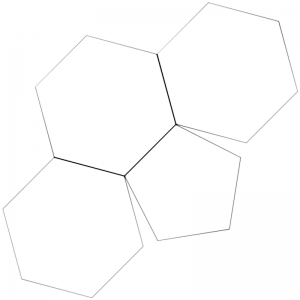

The truncated icosahedron is made of 20 hexagons and 12 pentagons. These can be divided evenly into four sets of 5 hexagons and 3 pentagons, but the shape would be too small if each of the sets was cut from a 4’x4′ board. Dividing further makes for two different sets, one with 3 hexagons and 1 pentagon, and one with 2 hexagons and 2 pentagons.

I made the shapes in Inkscape, and scaled them so the larger (3,1) shape just fit on the 4’x4′ sheet. I also traced the outline to make a cut-out path.

As a test, I printed out four of each of the shapes at 9% on paper, cut out the shapes and taped them together into a little version. Doge is not convinced, but it looks good to me.

With a mat knife, I cut the large foam core sheets into 4’x4’s. I used nine gaffer tape loops at the corners, sides, and center, to hold the sheet to the sacrificial layer.

The boards have a green side and a white side, which I used for the outsides of shape (2,2) and shape (3,1) respectively. For cutting, the outside is taped down to the sacrificial layer, so I took care to coordinate color with cut list.

The bit was the 1/2″ 60° V at 12,000 rpm and a feed rate of 4″/sec. The first cut was an outline of all the shapes at a depth of 0.450″, and the second cut was the silhouette of the shape at 0.525″, just outside the line. The cut through was only successful on one of the eight boards, leaving me to cut out the shapes with the mat knife.

Once all the pieces were cut, I began to tape them into 3D forms.

Pulling the sides together on the inside with gaffer tape made the 3D shape, and clear packing tape on the outside seams held them securely.

Pulling the sides together on the inside with gaffer tape made the 3D shape, and clear packing tape on the outside seams held them securely.

I taped all of the parts and stacked them, with the thought that I would carry all eight pieces to class and assemble them there.

A quick assembly test made it clear that putting eight par ts together would take too long. Perhaps assembling the whole, and taking pictures would be the way to go. Taking the parts out into the hallway, assembly with packing tape took about half an hour.

ts together would take too long. Perhaps assembling the whole, and taking pictures would be the way to go. Taking the parts out into the hallway, assembly with packing tape took about half an hour.

My plan to bring it to class involves cutting the finished object into two equal segments which will fit in a van, and an elevator. Once in the classroom, the segments will be taped together to make the big truncated icosahedron.