For my final project, as outlined in my Week 1 proposal, I wanted to build a “replica plating” device for mammalian cells.

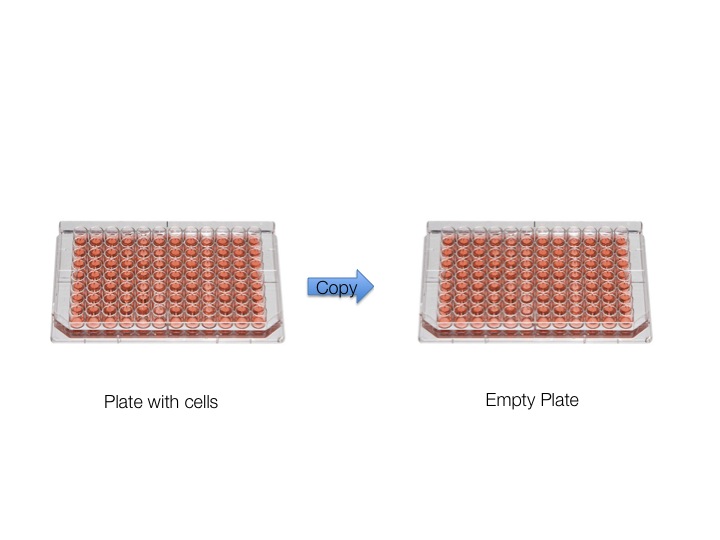

For certain high-throughput experiments, cells are grown in 96 well plates.

Each well is a separate experimental condition so a 96 well plate has 96 different conditions or cell types. One problem with this setup is that it is hard to split these cells into another 96 well plate, which you often want to do.

I would like to build a device that can do this mechanically, avoiding the need to pipet. This would be particularly useful for adherent cells.

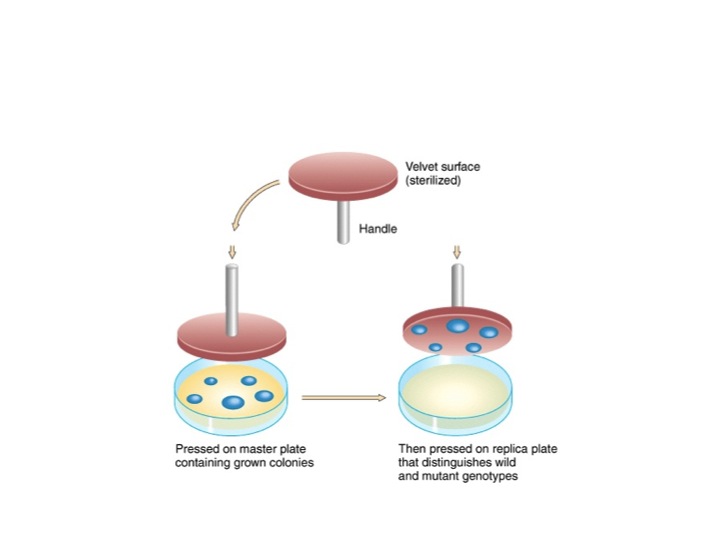

For bacteria or yeast, an analogous procedure can be done, called replica plating.

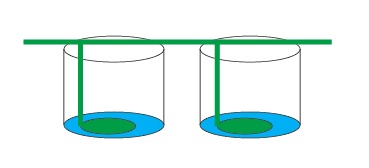

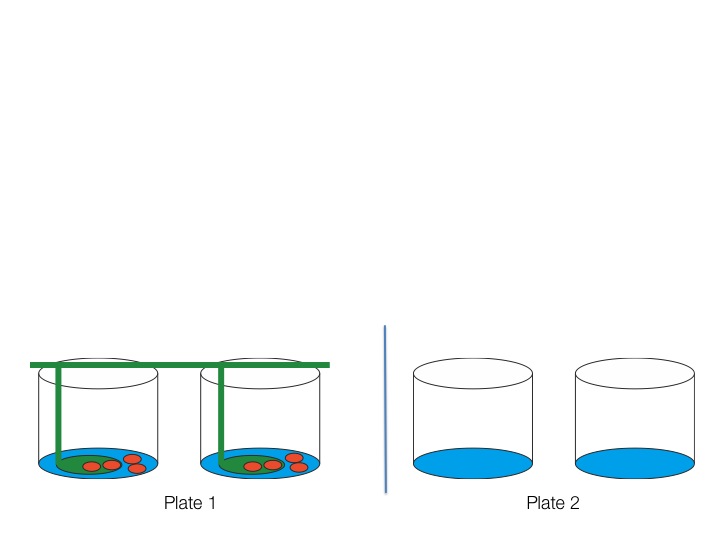

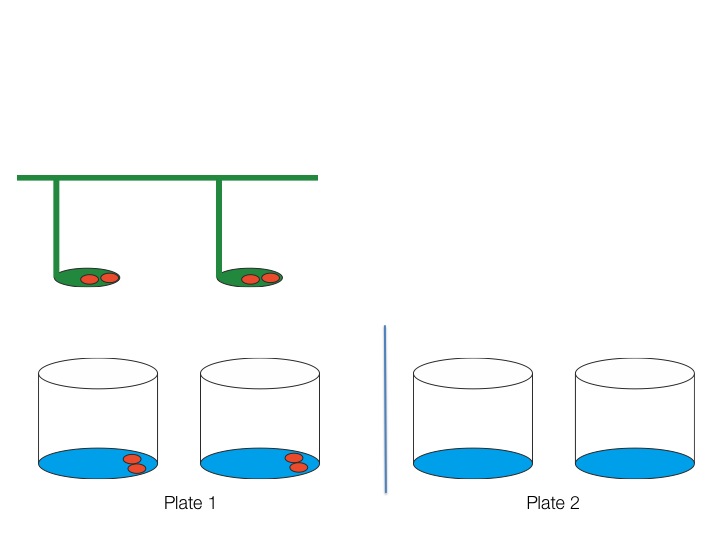

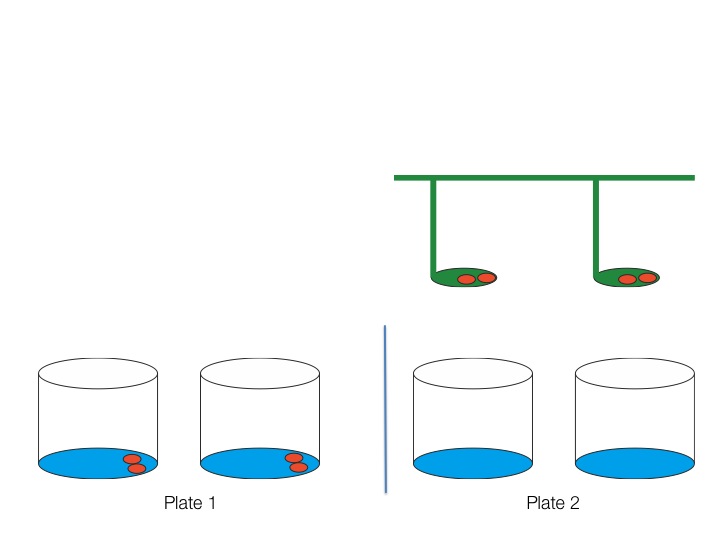

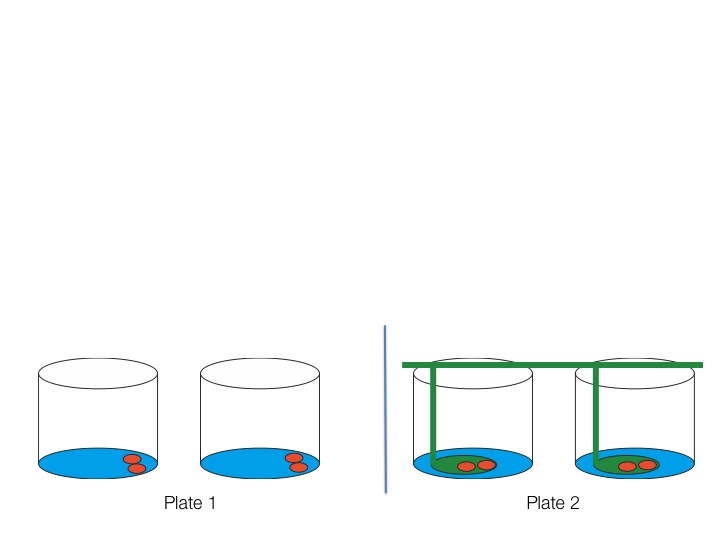

In the diagram below, the device is in green. It is basically a set of 96 small coverslips upon which the cells could grow, but connected to all of the other cover slips (illustrated here for 2 wells).

The idea would be to lift the connected coverslips and place them in a new 96 well plate, effectively making a copy of the original 96 well plate.

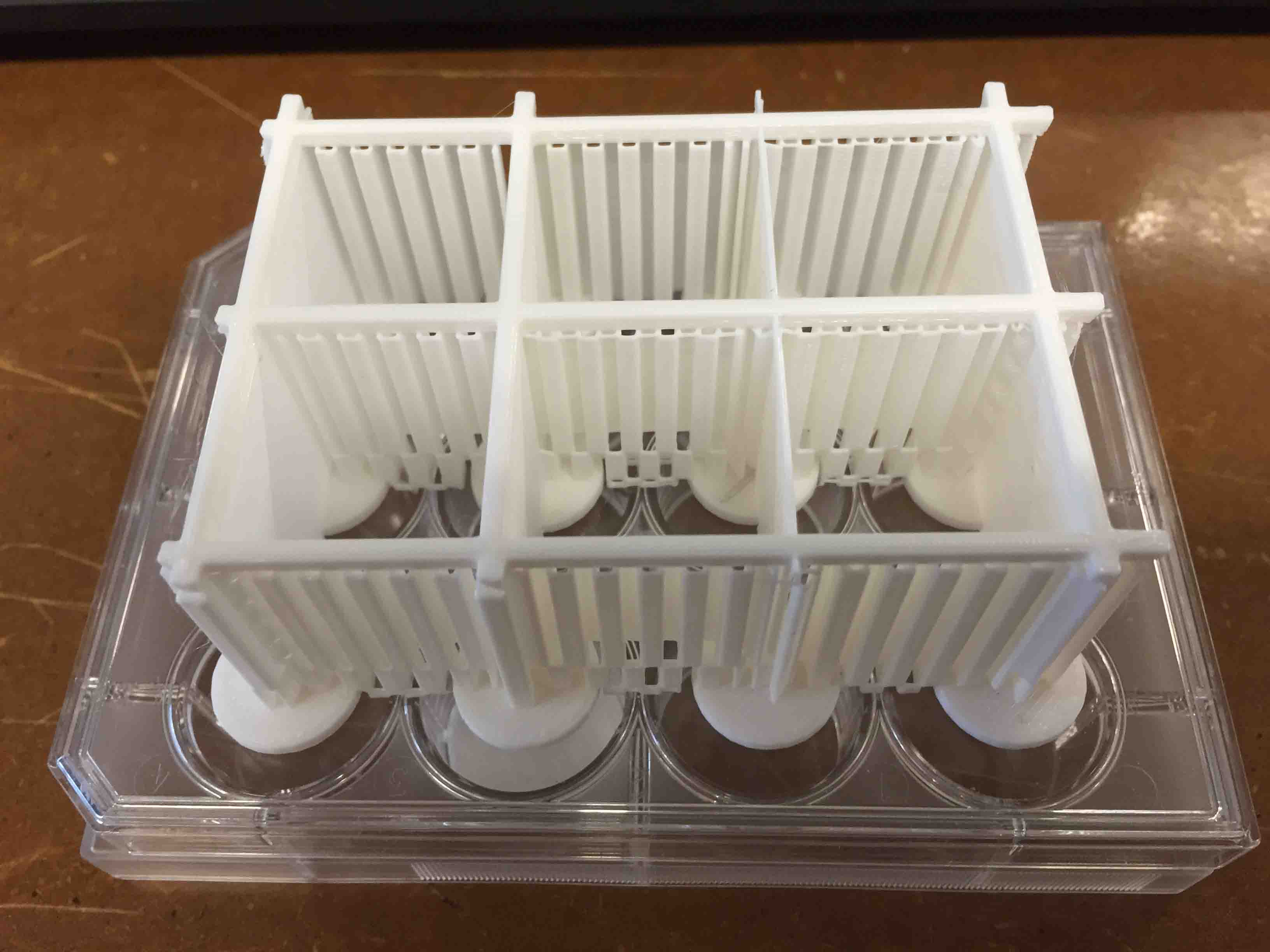

I decided to build a device for a 12 well plate instead of a 96 well plate here becuase I wasn't sure the resolution of the 3D printer in the Harvard lab, the MakerBot Replicator, would be good enough. The device would have to fit almost perfectly in the plate to work.

I designed my device in AutoCAD.

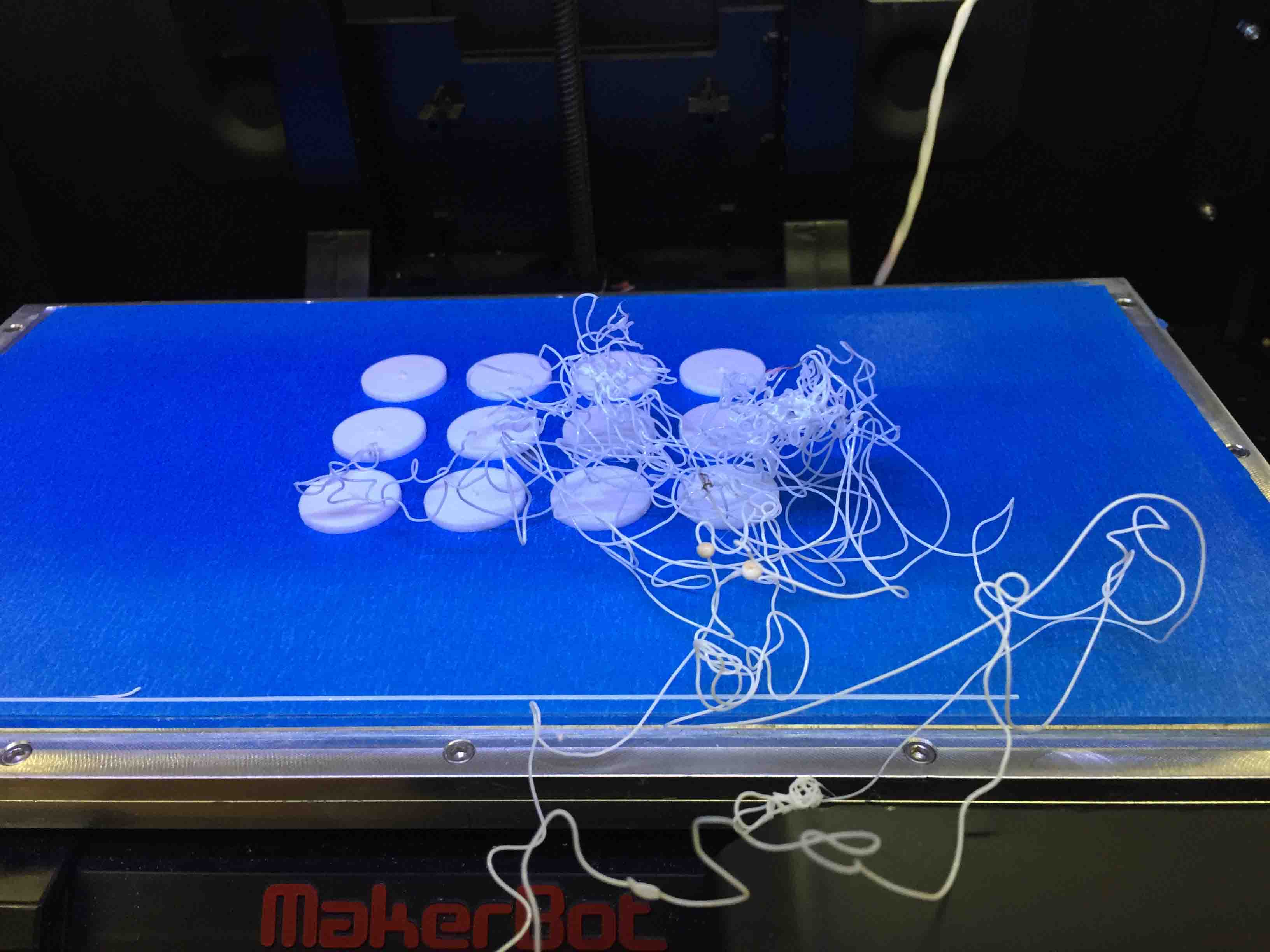

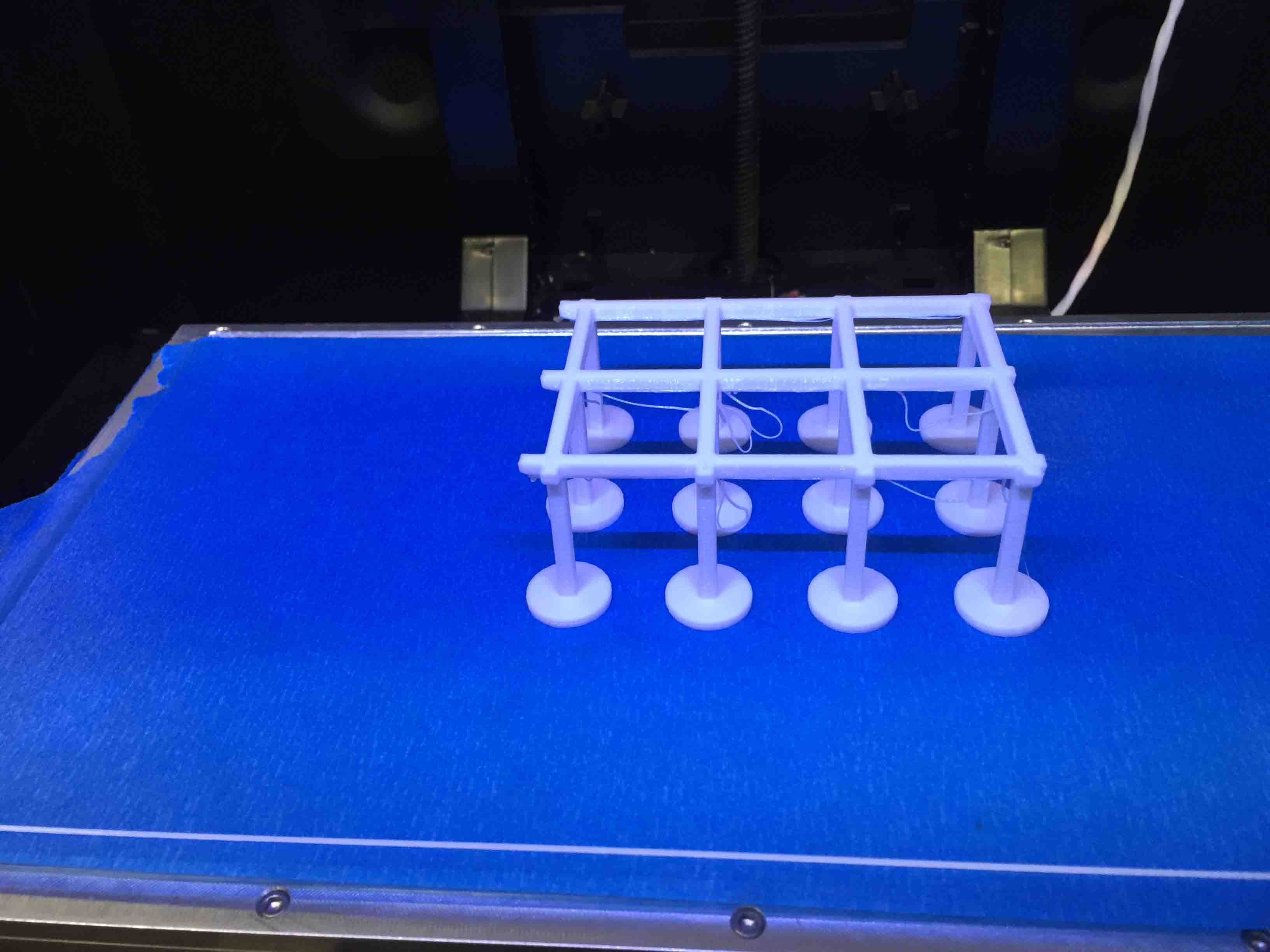

The first printing attempt failed. I think this may have been because the vertical rods were too thin.

I tried printing again with supports this time.

This worked but the supports were really bulky and difficult to take off without damaging the rest of the structure.

I modified my design to make the vertical rods thicker and printed without supports.

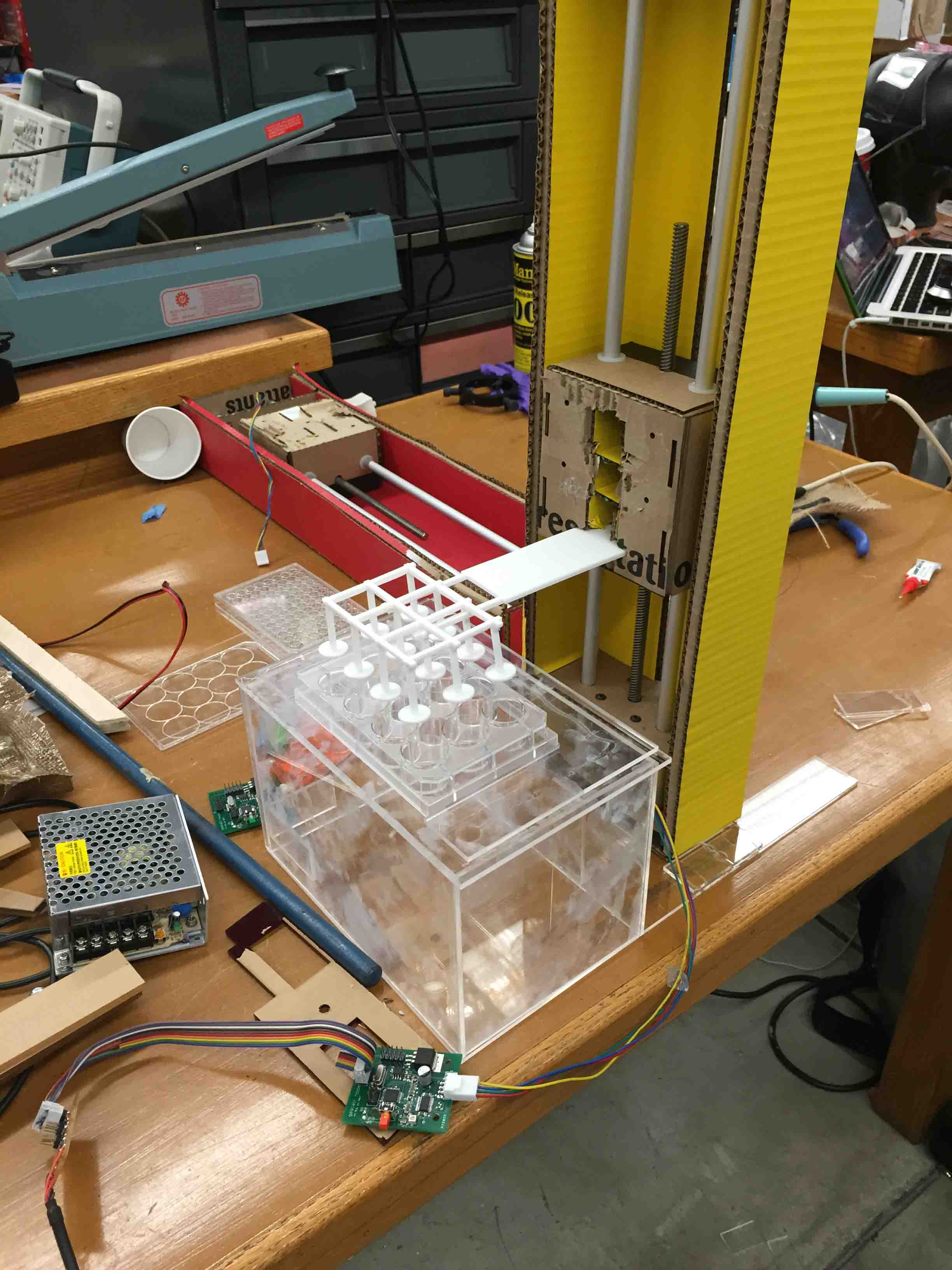

This finally worked. Then I designed the lifting device (for picking up my other device), also in AutoCAD.

I designed the parts of my stand in Adobe Illustrator.

And I cut them out using a laser cutter.

I attached the pieces using Super Glue. I had a piece that was exactly the width of my plate so that it would align correctly.

I tried progamming my bipolar stepper motor board from week 12. This was not successful. I, thus, resorted to using part of the device we made for the group project instead.

I could then use the stepper motor we used for the group project to lift the device.

The device worked in doing what I designed it to do.

The next step is to test that cells stick to the device (and can grow on the 3D printed material I used).