Electronics

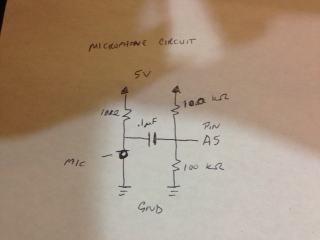

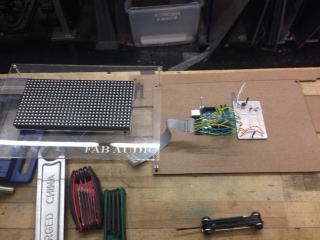

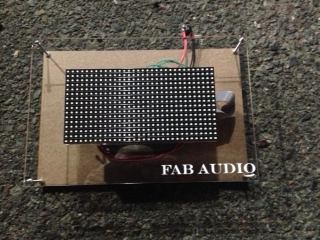

The electronics for this project weren't overly complicated. The components list is above. The link to the Adafruit website has an explanation on wiring the Matrix which I followed exactly and is much better documentation than what I would be able to do for it here. Below is a picture of the circuit I laid out for the microphone. It was a last minute addition...an attempt at a solution for the code problems I'm about to talk about. So basically on the electronics side of the house, switching over to using just Arduino meant that I had a couple of options. I could either take an analog input from some sort of device and run that through the FFT and matrix code, or I could probably work out a mono input but then depending on my computer I may or may not be able to generate that sound simultaneously if I plug in another set of speakers to the laptop. I didn't really have what I felt I needed on hand or time wise to attempt this so I went for the input device. I was concerned about having a lot of uncontrolled variables with an electronics heavy project, which is not my strong suit, so I chose to use an Arduino Uno that I already had on hand, rather than run a risk with the Fabduino. Although it would be nice to make one in the near future, I already had a mini circuitboard I was going to be stuffing anyway, and just like the Arduino the Fabduino isn't something I designed, so it didn't seem to matter to me which I used aside from saving some time soldering and praying that it wouldn't act up on me. The LED matrix I ordered was a little bit annoying...this is obviously a project that other people have undertaken before. There's plenty of articles I skimmed on instructables and youtube videos I filtered through to see it up and running. A key difference though was that my board from Adafruit doesn't use the HT1632C driver chip that a lot of other people had in their boards, so I wasn't able to apply a few things code wise and was working off of different libraries as well obviously. I originally had thought about building the matrix myself, but Charles said that hand soldering 512 LEDs to a scrap of copper wasn't really worth the time in the overall scope of the assignment. The other problem I'd have encountered with that is if I wanted the HT1632C driver chip (which I really did want) then it's not manufactured in the US. We looked everywhere--it would have gotten here from China some time in February.