Lessons Learned

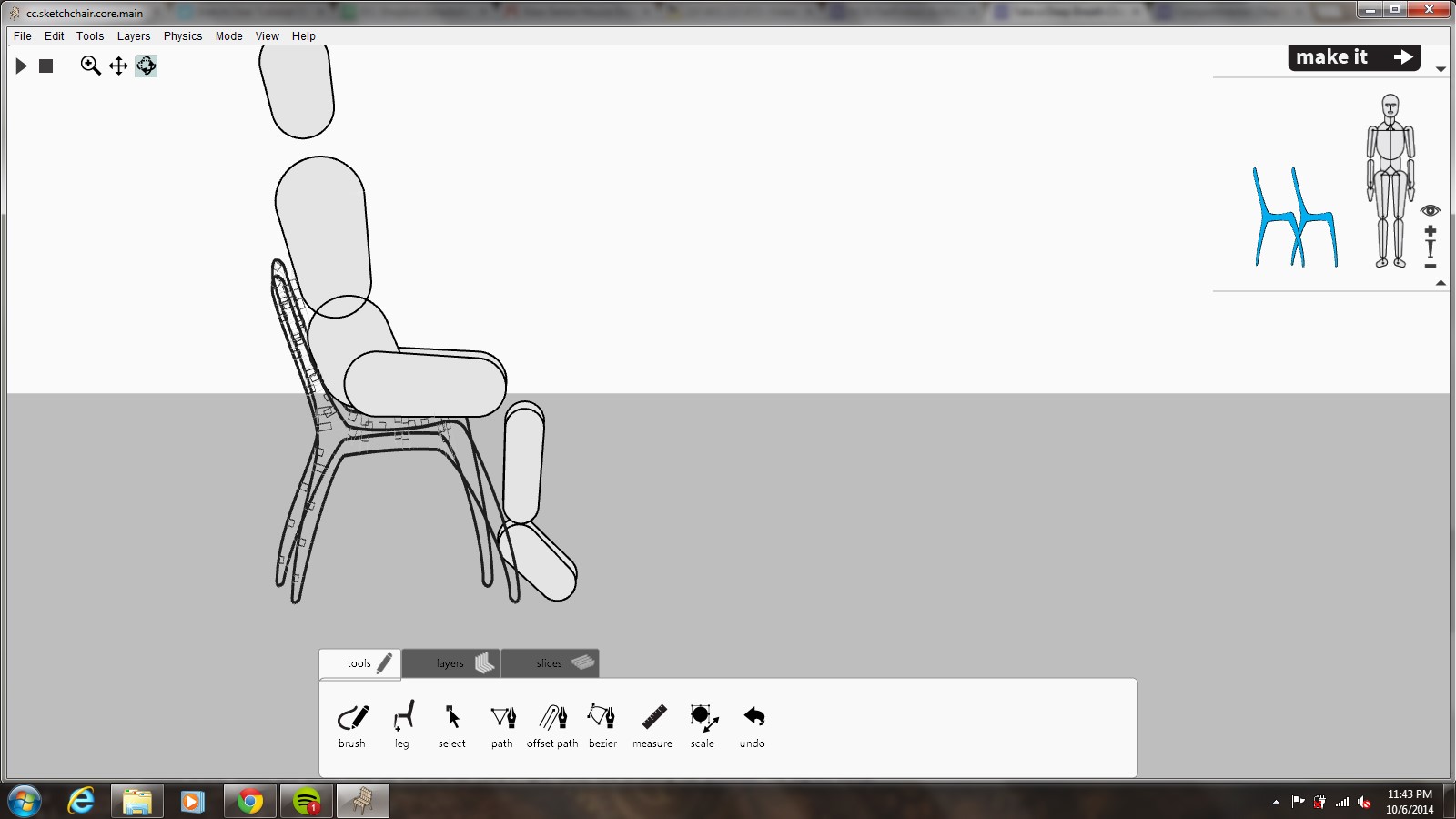

I definitely learned more this week about trouble shooting than I think I learned any other week...even the laser cutter and website development week. Here's my laundry list of problems and how I solved them: The very first problem that I had was generally struggling to learn how to use Sketchchair. Ultimately it was fine, but the lesson learned was that if I don't feel as though I have the time, it may be good to become particularly proficient on one high end program that can do everything I need to do (Solidworks for example). The problem with using Sketchchair was that I think it's a relatively new bit of software, and so it doesn't have a lot of tutorials or support developed for it yet. You're definitely on your own to learn it. The next problem I had was transferring the job and developing the tool paths. For whatever reason, my design uploaded with some open vectors (random missing small chunks of lines) that were tedious to find and made it so that the function wouldn't trace the tool path. Fortunately for me, I was able to actually edit it on the spot using a vector drawing tool, and trimming tool to cut out excess I no longer needed. With that you can link vectors to make it one single path. My next problem came from entering the wrong x-y dimensions. The job shut down halfway through because I was essentially telling it to move 8 feet horizontally on a bed that is no where near that big. So I had to go back into the tool path screen and flip the dimensions. Then I had to move some pieces around so they'd fit again and retrace all the tool paths. I didn't have to take the wood out of the bed fortunately, because I was able to keep the first part I cut the same. My final issue came from a poor assumption I made. I thought that the machine had saved the xy zero location. Apparently when you reset, this is not the case. So when I just went to run my project, it immediately started cutting off the bed with it's preset zeros. I actually may have done the zeroing location, but then forgotten to actually hit the zero button. Regardless, the mistake cost me a piece of material and I had to abort the job, reset it and run it again. After this though, smooth sailing and I got a decent looking chair out of it. Doesn't support me, but my cat sat in it the other day and apparently it can support her weight at least. In typical cat fashion though, she jumped out when I went to take a picture and I haven't been able to catch her in it since.