Molding and Casting

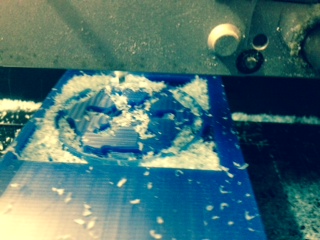

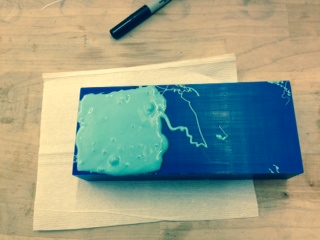

So this week we had the opportunity to try out some molding and casting. I've been a bit interested in this for awhile because work on a previous project had me strongly consider it as a way to cast a sleeve into a shell I was working with. Ultimately that's not what I ended up doing for several reasons, but I watched many very cool demonstrations on YouTube that made me want to try it out in some other context. This week was a bit difficult in terms of time because there were a lot of issues with the west section modela, and scheduling time to get on the machines due to how long the projects take also was tedious. Ultimately though I came out with a finished product that I'm relatively pleased with given that this is my first attempt. I am also going to add in a note that I forgot to take into account this week: It's to my benefit to pull often even if I'm not updating. Otherwise it takes forever and a second to get an updated version on my computer so I can merge/add/push whatever I'm doing with my information.