I started with a standard block of purple foam. As you can see I've already started to make the rough shape of it. To make the mold I decided to use a ghetto (no offense Charles it's still awesome and functional!) hot wire built by Charles Guan his freshman year as an undergrad at MIT. I ran it at 12 V and alternated between 2.7 and 3.3 Amps depending on how fine a cut I needed. The higher the current, the hotter and less precise the cuts get. The max current is 4.3 Amps which I definitely did not need for this project.

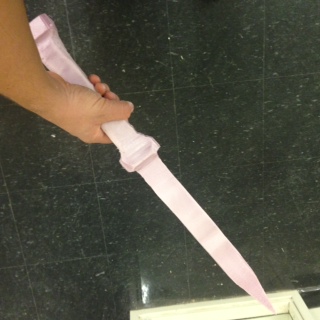

Final product before composite wrapping. Honestly I wish different foam had been on hand. I would have liked something a little bit firmer. I tried to clean this one up and shape the hilt to be more cylindrical with sand paper but the properties of the material weren't particularly conducive to that and small chunks came off at times.

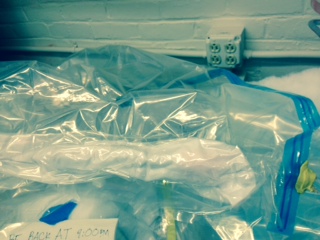

And here's the mold wrapped up and in the bag. I used the Epoxy 100 because it supposedly has a much shorter cure time. 2:1 ratio of that to the hardener. I slicked up the burlap with it and wrapped the entire mold. Then I followed up with the red sheet around it and two layers of cotton/cloth wrapping. The bag I chose to use was the vacuum sealing ziploc bag, but because of shopvac issues I used the continuous vacuum hooked up to it instead and made a seal with the yellow putty/tape. Hopefully it turns out relatively okay as a final product but we'll see tomorrow. This is going to be sitting overnight.